Phosphorus-containing fire retardant as well as preparation method and application thereof

A flame retardant, flame retardant finishing technology, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of poor water solubility, poor smoke suppression, difficult application, etc., and achieve the effect of good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

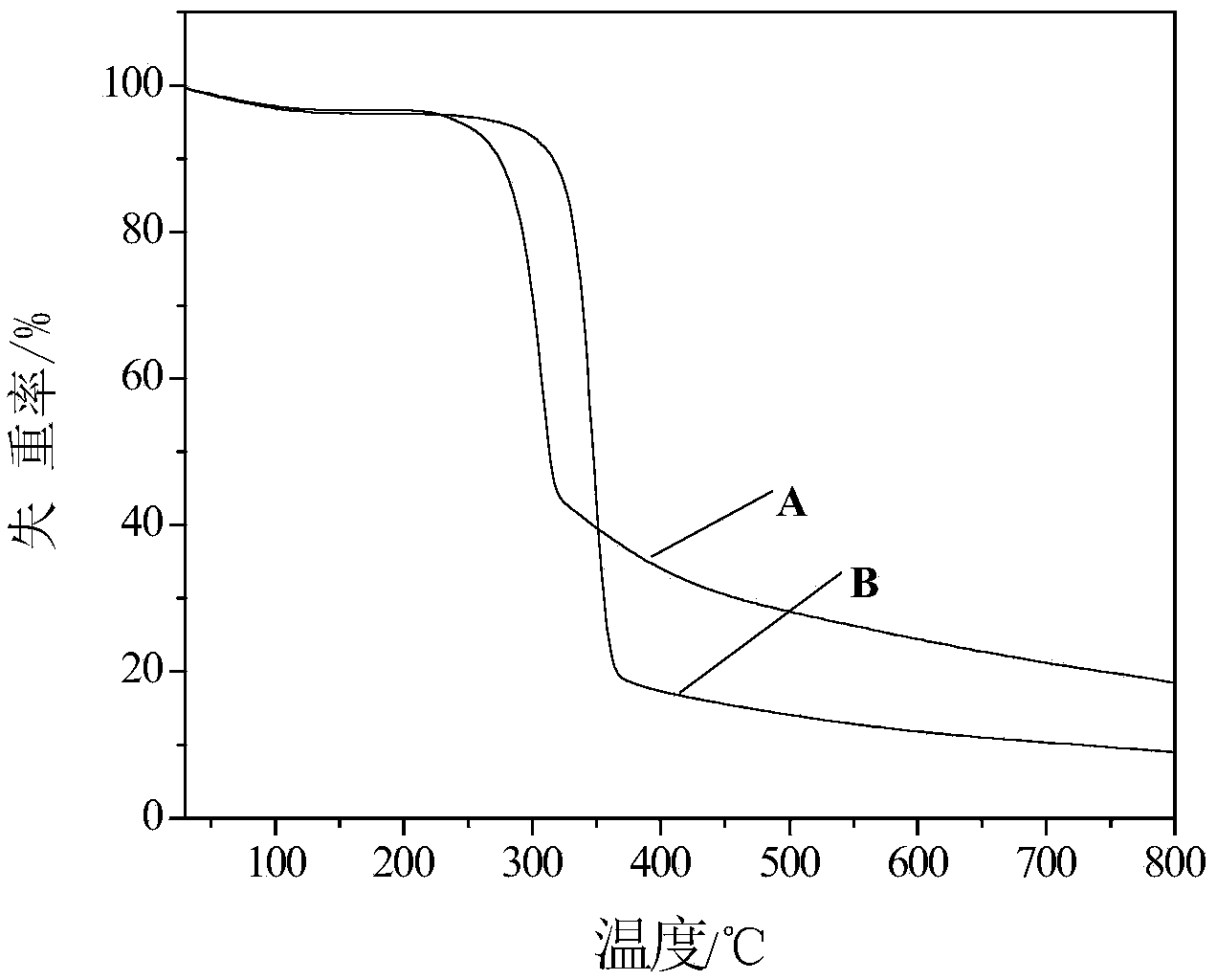

Image

Examples

specific Embodiment approach 1

[0025] Specific implementation mode 1: A phosphorus-containing flame retardant of this embodiment, a general structural formula of a phosphorus-containing flame retardant is:

[0026] Said n is 8-16.

[0027] This phosphorus-containing flame retardant is a cyclophosphazene degradable chitosan derivative JCHP.

specific Embodiment approach 2

[0028] Specific embodiment two: the preparation method of a kind of phosphorus-containing flame retardant described in this embodiment is carried out according to the following steps: mix hexachlorocyclotriphosphazene and diethyl ether and stir to dissolve to obtain mixture A, and then add it to mixture A Adding chitosan and pyridine degraded with a mass concentration of 6% hydrogen peroxide, and stirring and reacting for 14h to 20h at a temperature of 20°C to 25°C and a stirring speed of 500rpm to 700rpm to obtain a mixture B, Then add absolute ethanol to the mixture B and let it stand for 12h-24h, suction filter to obtain the crude product, wash the crude product with diethyl ether for 3-5 times, and then use the volume percentage of 30%-50% methanol solution as the extraction The agent is subjected to Soxhlet extraction and purification, Soxhlet extraction and purification for 24h-48h to obtain the pure product, and finally the pure product is vacuum-dried at a temperature o...

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment is different from Embodiment 2 in that: the degree of polymerization of chitosan degraded by 6% hydrogen peroxide is 8-16. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com