Ultrahigh-voltage charged insulator cleaning agent and preparation method thereof

A cleaning agent, ultra-high pressure technology, applied in detergent compositions, chemical instruments and methods, non-surface active cleaning solvents, etc., can solve the problems of incomplete removal, corrosion of components, corrosion of silicone rubber components, etc. The effect of preventing flashover phenomenon, easy realization, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

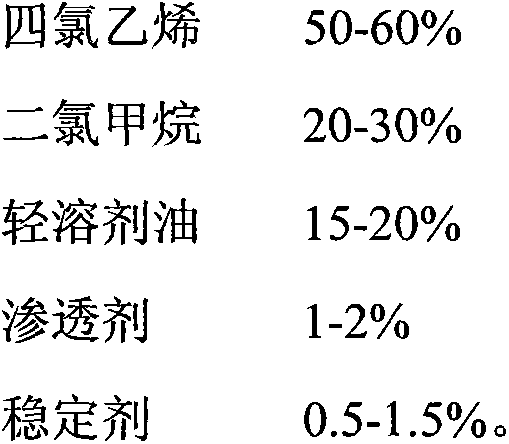

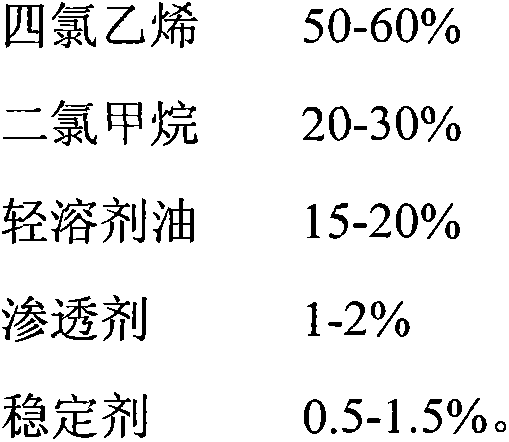

[0017] (1) Prepare 100kg ultra-high voltage live insulating cleaning agent:

[0018] 50kg of tetrachlorethylene, 30kg of dichloromethane, 18kg of light solvent oil, 1kg of penetrant and 1kg of stabilizer;

[0019] (2) Put the above-mentioned raw materials into a stainless steel stirring tank and stir for 25 minutes, then put them into a stainless steel storage tank at 20° C. and react for 4 hours.

[0020] The light solvent oil is 200# solvent oil, the penetrating agent is ethyl silicone oil, and the stabilizer is a mixture of heptane, cyclohexane, dodecane and decane. Among them, 0.2 kg of heptane, 0.3 kg of cyclohexane, 0.2 kg of dodecane, and 0.3 kg of decane.

Embodiment 2

[0022] (1) Prepare 100kg ultra-high voltage live insulating cleaning agent:

[0023] 60kg of tetrachlorethylene, 20kg of dichloromethane, 16.5kg of light solvent oil, 2kg of penetrant and 1.5kg of stabilizer;

[0024] (2) Put the above-mentioned raw materials into a stainless steel stirring tank and stir for 20 minutes, then put them into a stainless steel storage tank at 10° C. and react for 4 hours.

[0025] The stabilizer is a mixture of heptane, cyclohexane, dodecane and decane. Among them, 0.3 kg of heptane, 0.2 kg of cyclohexane, 0.5 kg of dodecane, and 0.5 kg of decane.

[0026] All the other are as embodiment 1.

Embodiment 3

[0028] (1) Prepare 100kg ultra-high voltage live insulating cleaning agent:

[0029] 55kg of tetrachlorethylene, 25kg of dichloromethane, 18kg of light solvent oil, 1.5kg of penetrant and 0.5kg of stabilizer;

[0030] (2) Put the above-mentioned raw materials into a stainless steel stirring tank and stir for 25 minutes, then put them into a stainless steel storage tank at 15° C. and react for 3 hours.

[0031] Described stabilizer is decane.

[0032] All the other are as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com