Bonding wire annealing system

A bonding wire and annealing technology, used in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problem that the annealing system is difficult to meet the demand, and achieve the effect of high smoothness and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

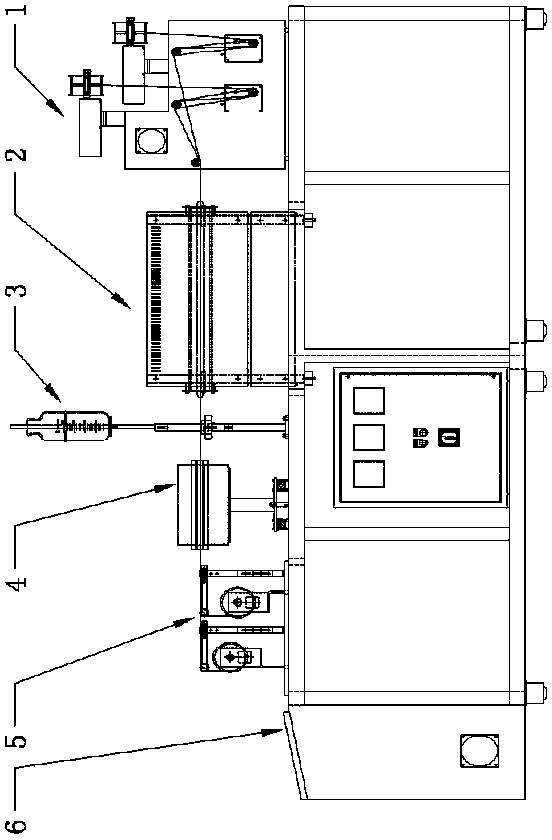

[0038] Such as figure 1 As shown, it is a preferred embodiment of a bonding wire annealing system of the present invention. This machine is mainly used for annealing gold wires of Φ0.015 to Φ0.05mm and other metal wires, etc., including: a wire-feeding system 1, composed of The metal wire released by the pay-off system enters an annealing furnace 2 for annealing, and the annealed metal wire is cooled by a drop device 3, and the cooled metal wire enters a dryer 4 for drying, and the dried metal wire is The wire enters a take-up system 5, and all the above-mentioned systems are controlled by a main control system 6, which is composed of PLC and touch screen.

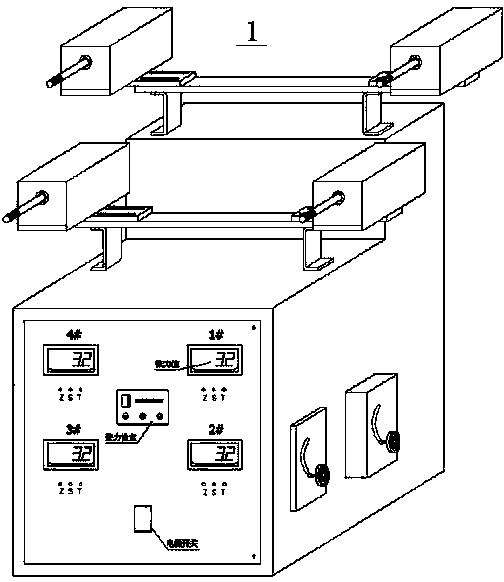

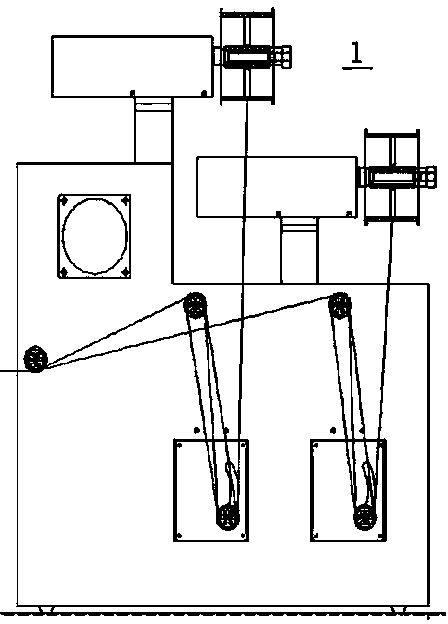

[0039] Such as figure 2 , image 3 As shown, it is the outline drawing of the pay-off system and the winding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com