Centrifugal model test wave cyclic loading simulating device and testing method thereof

A technology of centrifugal model test and simulation equipment, which is applied in the direction of impact test, machine/structural component test, measuring device, etc. It can solve the problem that the wave force cannot be simulated for a long time, the existing technology is difficult to achieve accurate control, and the unfavorable geotechnical centrifugal model layout and other issues, to achieve the effect of convenient regulation, large amplitude and long duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 - Geotechnical centrifuge model test research of box-type foundation breakwater.

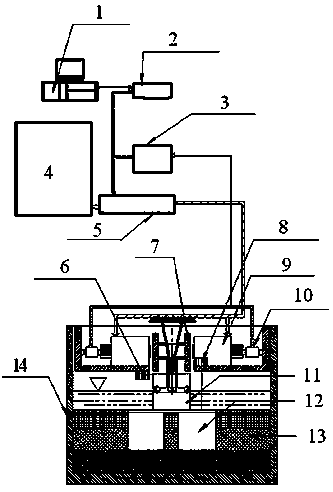

[0041] See figure 1 As shown, the equipment consists of three parts: control part, drive part and output part. The control part is composed of industrial computer, control software, data acquisition card, signal conditioning and adapter, which is used to issue instructions, receive signals from the drive part and output part, and control the characteristic values of the simulated wave force (amplitude, frequency, Wave pressure to wave suction ratio, action time); the driving part includes the driving power supply and the driving power amplifier; the output part includes the exciter, laser displacement sensor, force sensor and armature. In the figure, industrial computer and its control software 1, acquisition card 2, signal conditioning and transfer 3, driving power supply 4, driving power amplifier 5, horizontal displacement laser displacement sensor 6, armature 7, settlemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com