Femtosecond laser fabrication device and method for sampling fiber Bragg grating SFBG

A technology of Bragg grating and femtosecond laser, which is applied in cladding optical fiber, optical waveguide and light guide, laser welding equipment, etc., can solve the problem that the sampling period and duty cycle cannot be continuously adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

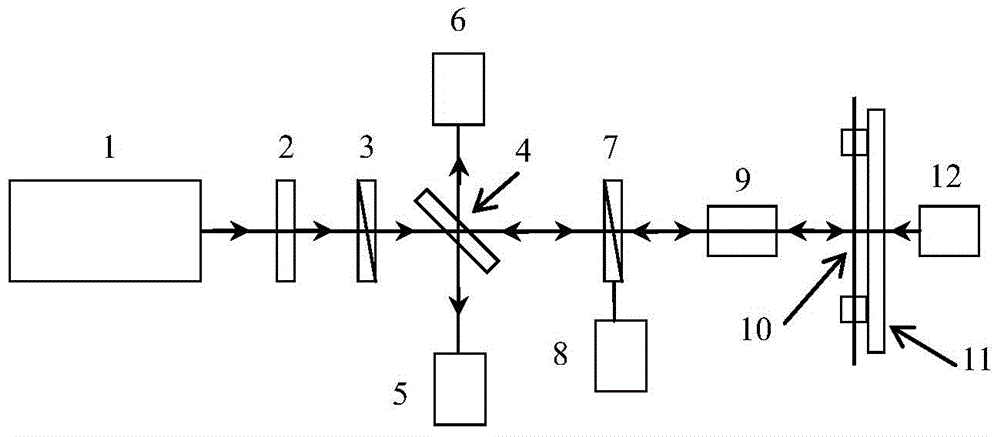

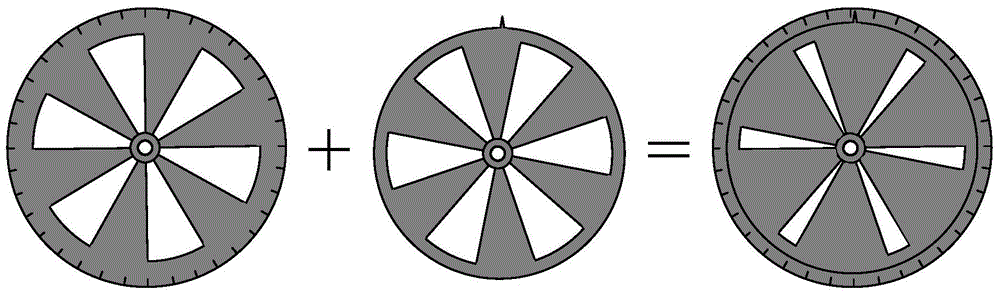

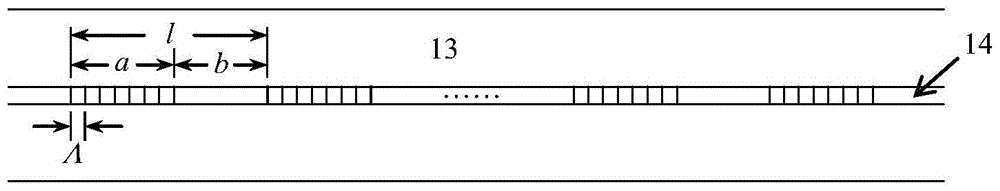

[0036] Embodiment of the present invention: the femtosecond laser output from the titanium-doped sapphire femtosecond laser system is combined with a 1 / 2 wave plate and a polarizer to adjust its energy, and then split into beams by a half-transparent and half-mirror. The reflected laser light is received by an optical power meter for monitoring the energy of the femtosecond laser light. The laser beam passing through the half-mirror is modulated by an optical chopper, and the modulated femtosecond laser is focused by a high-magnification microscope objective lens, so that the focus of the focused beam is located on the fiber core, and the fiber is held by two fiber holders It is fixed on a high-precision three-dimensional micro-displacement platform, and the optical fiber is moved at a constant speed along the longitudinal direction (perpendicular to the laser be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com