An automatic load shedding system and method for ultra-high voltage long-distance transmission line faults

A line fault and load shedding technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as difficult to avoid switching off orders, heavy operations by operators, and fire extinguishing of units, so as to reduce hardware investment cost, improve system stability, and reduce operational intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following describes the ultra-high voltage remote transmission line fault automatic load shedding system and its method according to the embodiments of the present invention with reference to the accompanying drawings.

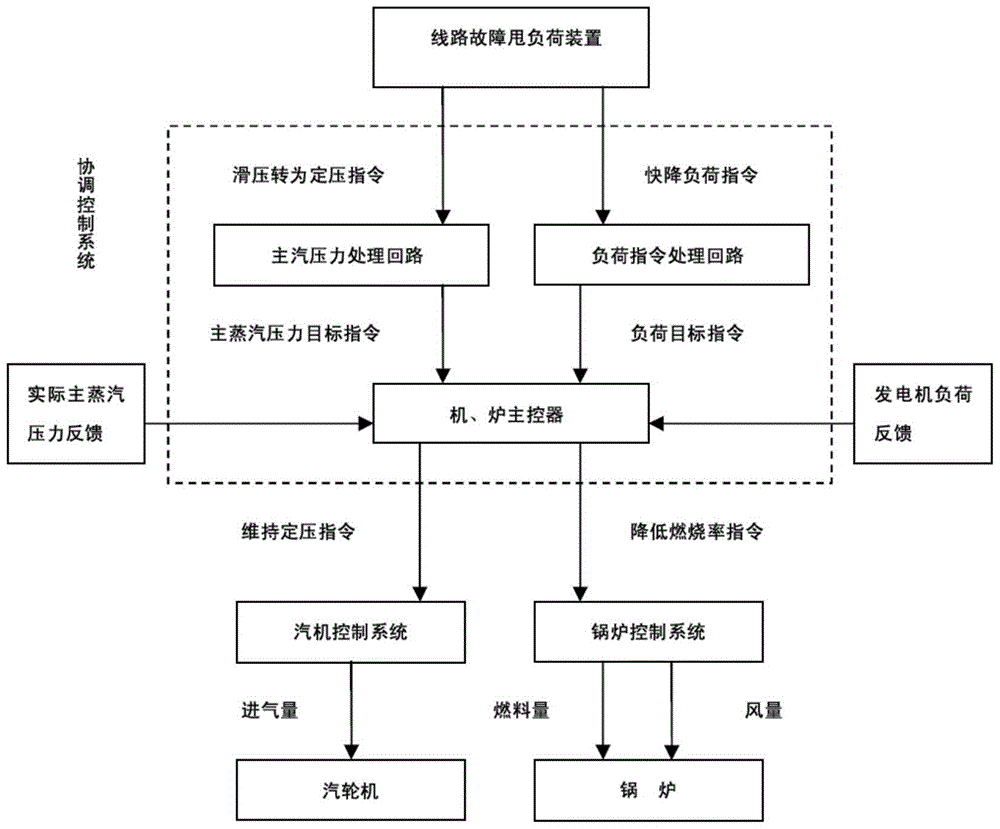

[0034] figure 1 It is a structural schematic diagram of an ultra-high voltage long-distance transmission line fault automatic load shedding system according to an embodiment of the present invention.

[0035] like figure 1 As shown, the line failure unit automatic load shedding system includes: line failure load shedding device, coordination control system, boiler control system, steam turbine control system, boiler, steam turbine.

[0036] The line fault load shedding device includes a start button. When the start button is pressed, the line fault automatic load shedding function will be triggered. The line fault load shedding device will automatically generate a line fault quick load reduction command and a sliding Commands are sent to the coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com