A pouring system for metal ultra-thin shell

A gating system and metal melt technology, which is applied in the field of gating systems for metal ultra-thin shells, can solve the problem of the lack of high fluidity of the metal melt, the inability to achieve stable and orderly filling, and the impact on the quality of metal ultra-thin castings To achieve the effect of improving product yield, enhancing filling ability and stability, and balancing flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described in conjunction with the following examples.

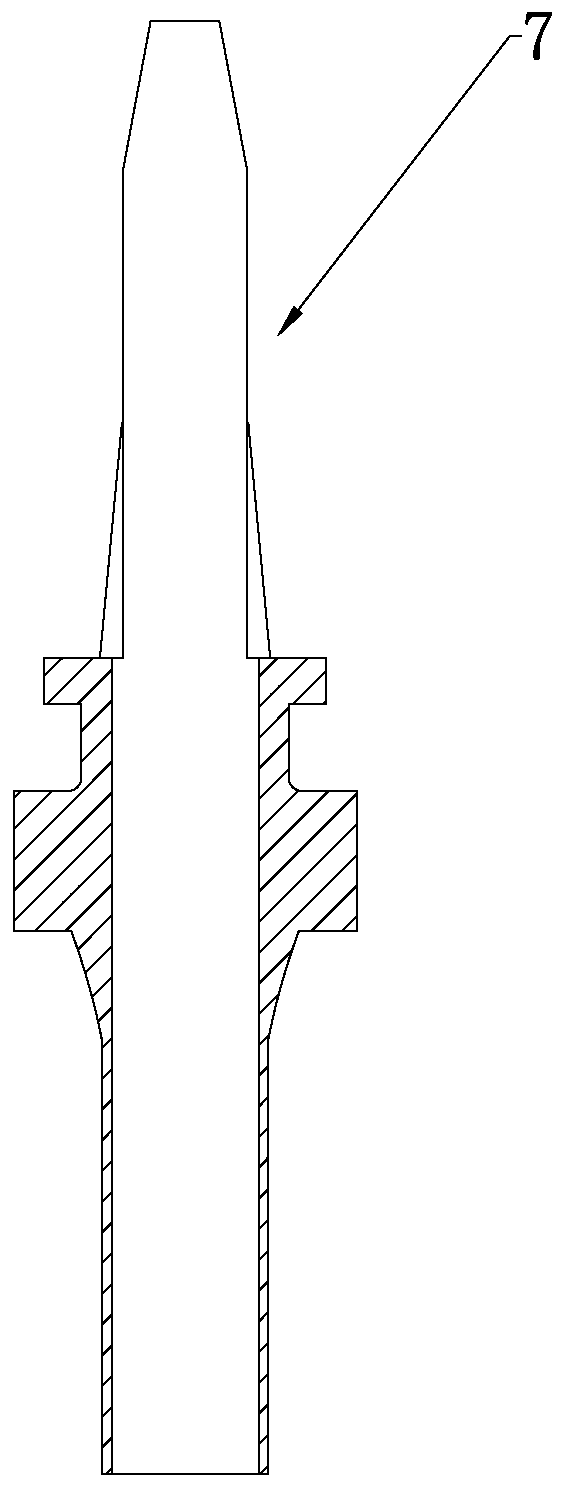

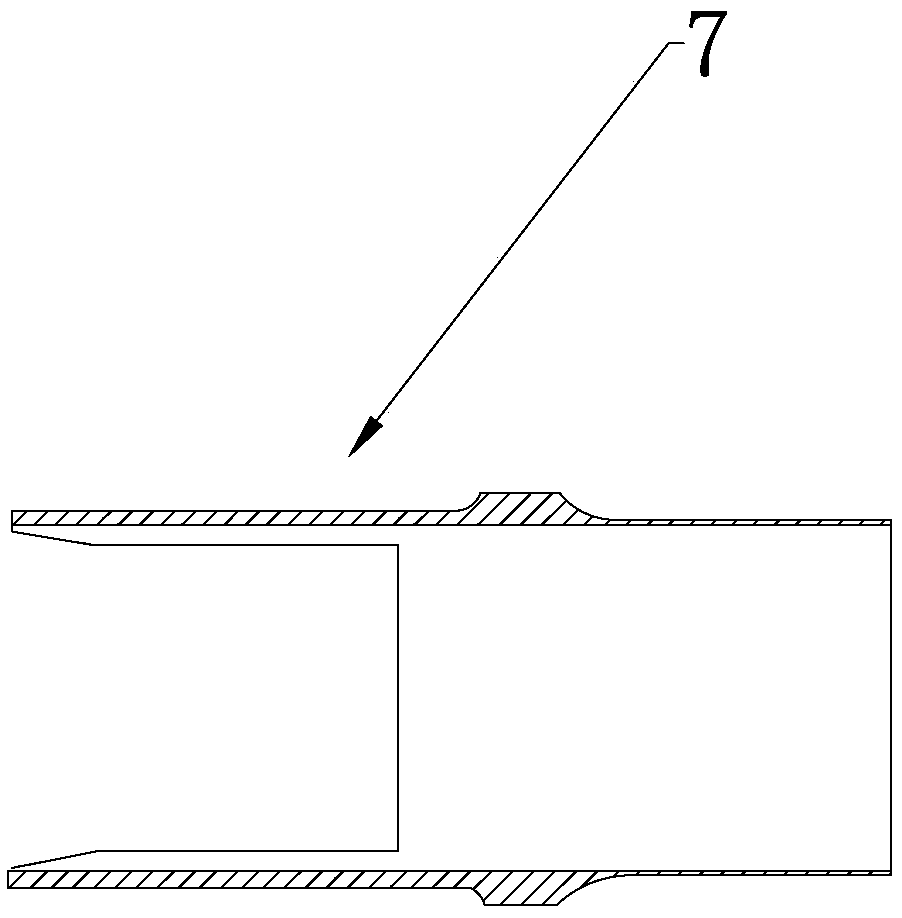

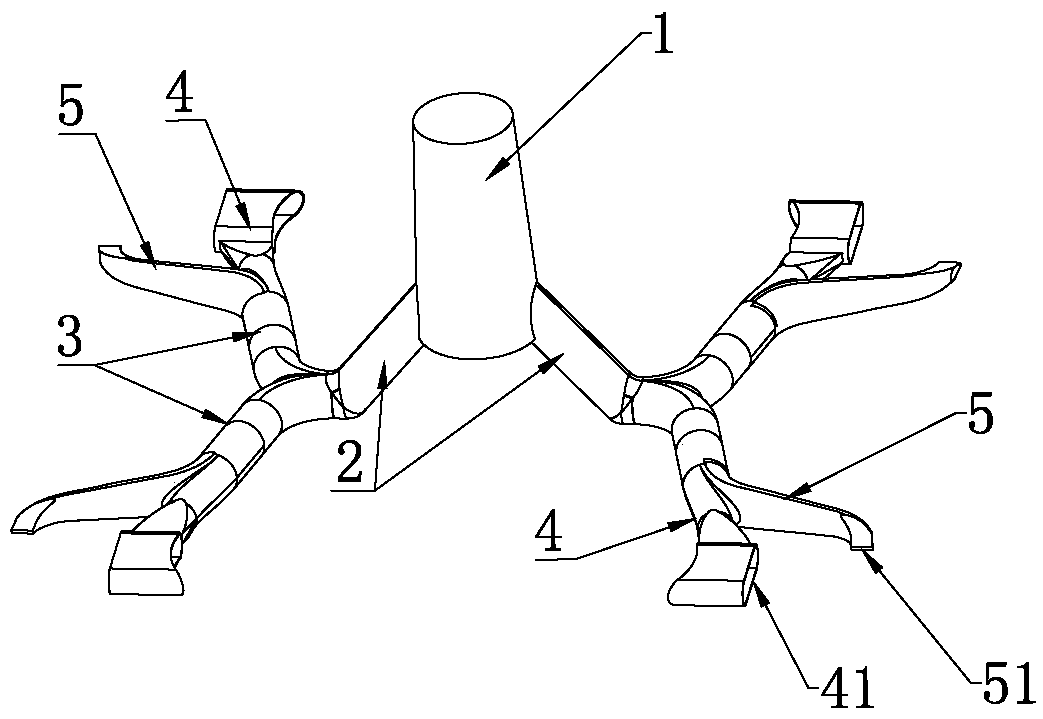

[0032] The gating system of a metal ultra-thin shell in this embodiment is as follows: image 3 and Figure 4 As shown: it includes a runner structure, a metal ultra-thin shell 7 and several overflow bags 6, and the runner structure includes a sprue 1, a runner 2, an ingate and an ingate connected in sequence, in order to improve Production efficiency, the sprue 1 is extended with two runners 2, each runner 2 is extended with two sub-runners 3, and each sub-runner 3 is extended with two inner runners, the sprue 1. The runner 2, the sub-runner 3, and the inner runner are all connected in turn by the arc runner, and the cross-sectional areas of the sprue 1, the runner 2, the sub-runner 3, and the inner runner are in order Gradually decrease to ensure that the molten metal entering the cavity 8 is stable and orderly.

[0033] Such as image 3 and Figure 4 As shown, one end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com