A complex trajectory research and throwing equipment for natural diamond knife blade grinding

A diamond tool and equipment technology, applied in the field of precision and ultra-precision machining, can solve the problems of unsatisfactory machining stability, single running track, easy aging of equipment, etc., achieve system stability and good economic practicability, and improve sharpening quality. , the effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

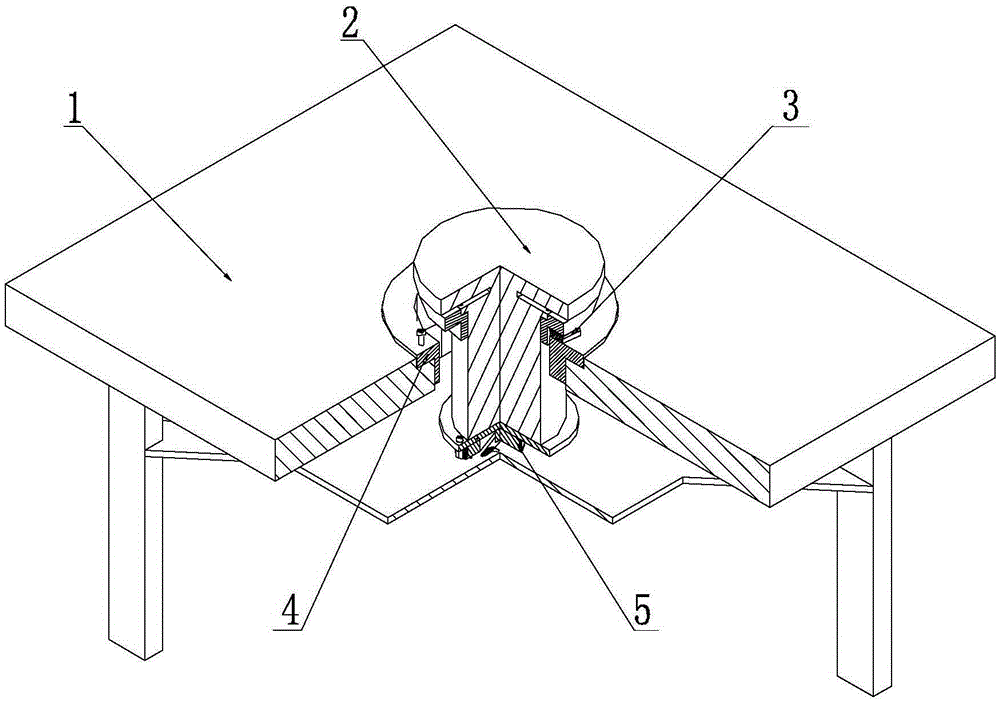

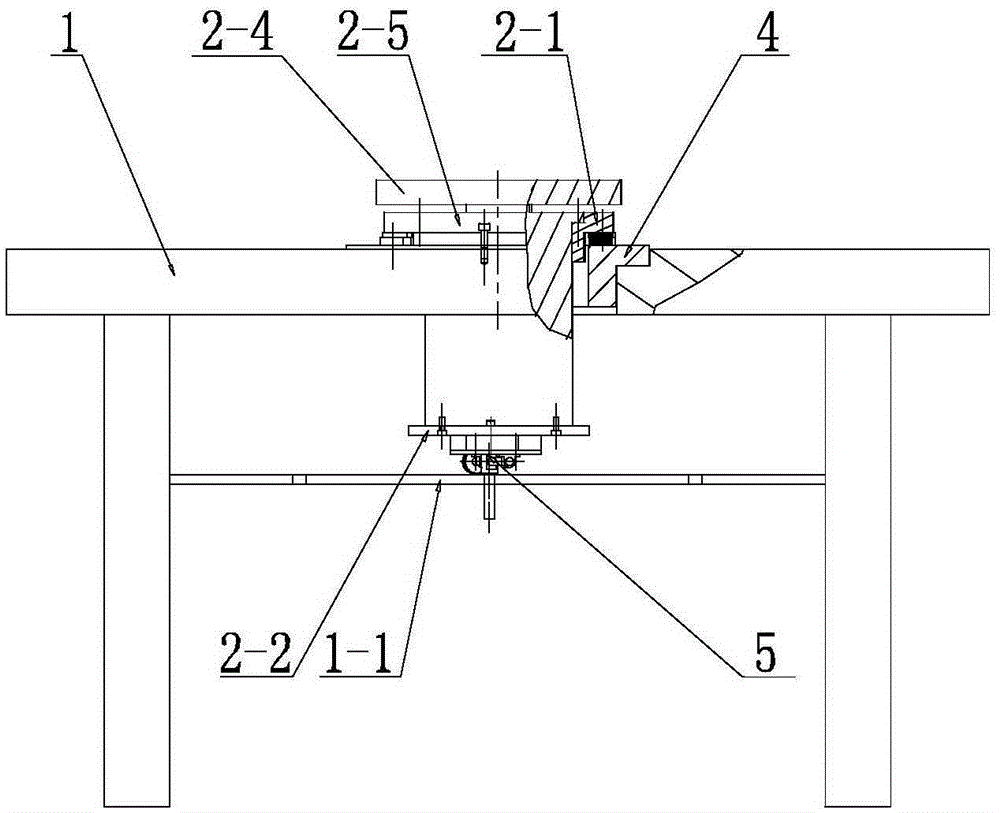

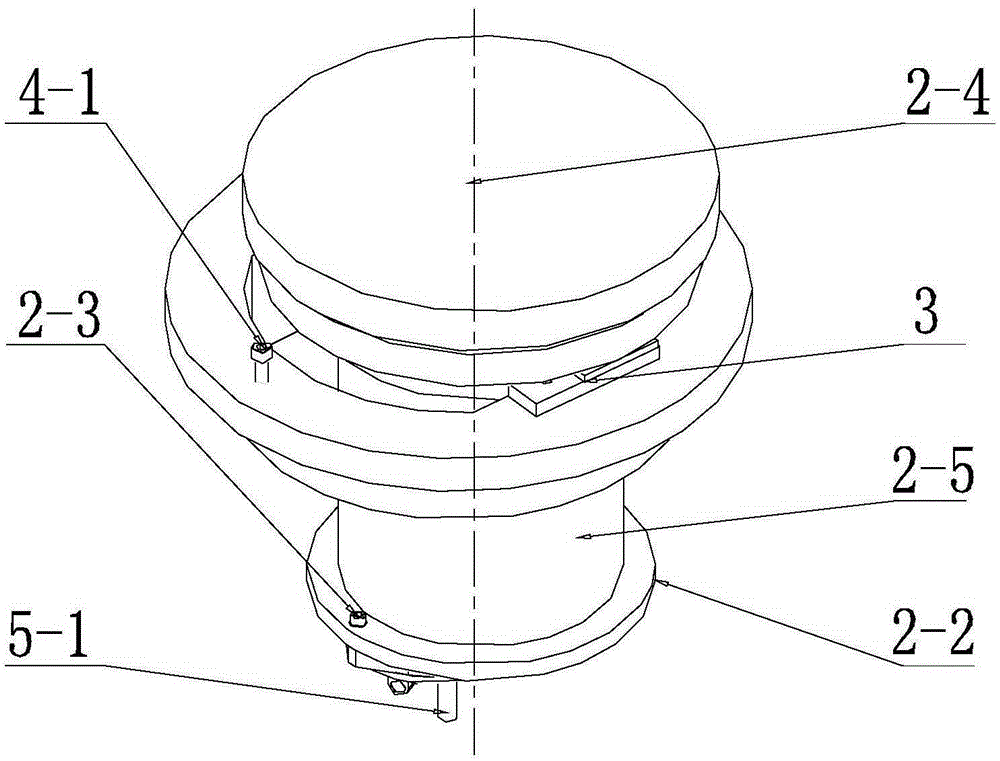

[0020] Specific implementation mode one: combine Figure 1-Figure 4Describe this embodiment. The equipment in this embodiment includes a bed 1, an air-floating spindle shaft system 2, a precision guide rail pair 3, a thrust air-bearing bearing 4, and a mechanism control component 5. The air-floating spindle shaft system 2 includes The supporting plate 2-1, the main shaft lower supporting plate 2-2, the first positioning locking screw 2-3 and the main shaft 2-5, the mechanism control part 5 includes the drive shaft 5-1, the self-aligning screw 5-2, Locking support 5-3, connecting rod 5-4 and eccentric wheel 5-5;

[0021] A thrust air bearing 4 is installed on the bed 1, an air bearing spindle shaft system 2 is installed inside the thrust air bearing 4, an upper spindle supporting plate 2-1 is installed on the upper part of the spindle 2-5, and a spindle upper supporting plate 2 -1 is installed together with the thrust air bearing 4 through the precision guide rail pair 3, and ...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the equipment of this embodiment further includes a grinding and polishing disc 2-4, and the top end of the main shaft 2-5 is installed with the grinding and polishing disc 2-4. Other implementation manners are the same as the specific implementation manner 1.

[0024] Working principle: When the first positioning locking screw 2-3 fixes the eccentric wheel 5-5 and the connecting rod 5-4 as one and the second positioning locking screw 4-1 is loosened, due to the drive shaft 5-1 and the installation The thrust air bearing 4 with the precision guide rail pair 3 has a certain amount of eccentricity. Through the coupling of the linear motion of the precision guide rail pair 3 and the circular motion of the thrust air bearing 4, a rotary guide rod mechanism is formed to realize air bearing The main shaft shaft system 2 is in the compound motion form of sinusoidal and circular superimpositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com