Modified asphalt waterproofing coiled material with self-adhering layer and preparation method thereof

A technology of waterproofing membrane and modified asphalt, which is applied in the directions of bituminous material adhesives, bitumen layered products, chemical instruments and methods, etc. Good thermal performance, waterproof performance and good extension performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

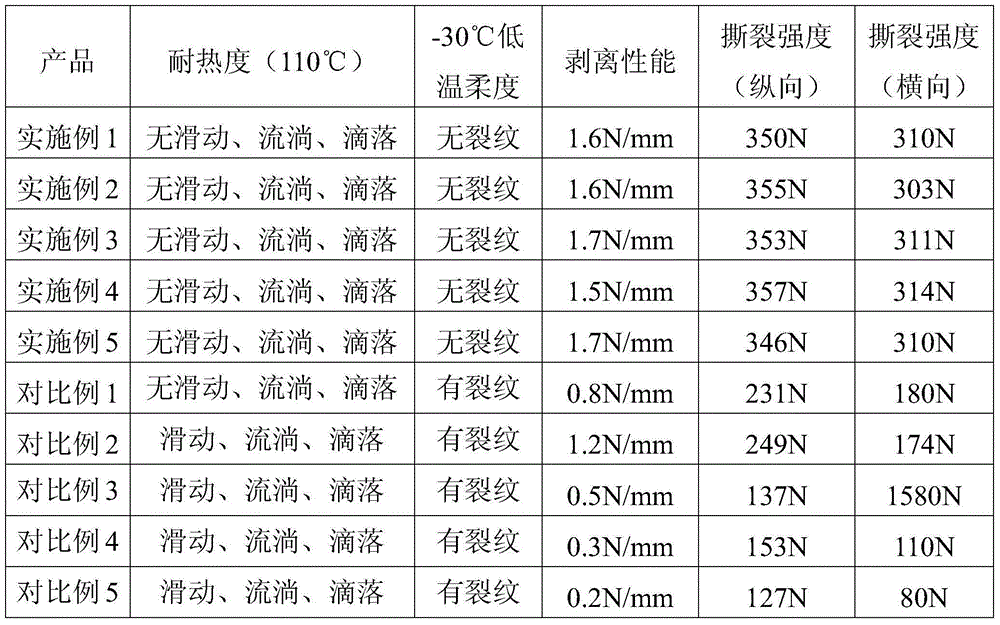

Examples

Embodiment 1

[0023] a. Preparation of self-adhesive layer: take 2250kg90 # Asphalt is heated to 200℃, then add 600kg of 40 mesh rubber powder while stirring, heat up to 255℃, stir at constant temperature for 2 hours, cool to 190℃, add 450kg naphthenic oil, stir for 8 minutes, then add 260kg SBS and 150kg SBR, at 180℃ Stir for 1 hour under the conditions, then grind for 1 hour, then add 125kg of hydrogenated petroleum resin, 800kg of 200 mesh stone powder, 8kg of ultraviolet absorber and 3kg of antioxidant, and stir for 1 hour at 180°C to obtain a prepared self-adhesive layer;

[0024] b. Preparation of asphalt layer: take 1200kg10 # Asphalt and 1000kg90 # After the asphalt is mixed, heat up to 200°C, add 800kg of 40 mesh nylon rubber powder, heat up to 260°C, stir at constant temperature for 2 hours, cool to 190°C, add 360kg minus three-line engine oil, mix well, add 200kg SBS, 100kg APP and 200kg at 180°C 100kgPP is oxidized for 1.5 hours, and then ground for 1.5 hours. Add 1400kg of 200 mesh...

Embodiment 2

[0027] a. Preparation of self-adhesive layer: take 2000kg90 # The asphalt was heated to 195°C, then 500kg of 40 mesh rubber powder was added while stirring, heated to 250°C, stirred at constant temperature for 2.5 hours, cooled to 185°C, 400kg naphthenic oil was added, stirred for 5 minutes, and then 200kg SBS and 130kg SBR were added at 185°C Stir for 1.5 hours under the conditions, then grind for 1.5 hours, then add 100kg of hydrogenated petroleum resin, 850kg of 200 mesh stone powder, 10kg of ultraviolet absorber and 1kg of antioxidants, and stir for 0.5 hours at 175℃ to obtain a prepared self-adhesive layer;

[0028] b. Preparation of asphalt layer: take 1300kg10 # Asphalt and 900kg90 # After the asphalt is mixed, heat up to 205°C, add 900kg of 60 mesh nylon rubber powder, heat up to 265°C, stir at constant temperature for 2.5 hours, cool to 195°C, add 320kg minus three-line engine oil, mix well, add 250kg SBS, 120kg APP, and Oxidize 80kg PP for 1 hour, then grind for 1.5 hour...

Embodiment 3

[0031] a. Preparation of self-adhesive layer: take 2500kg90 # The asphalt was heated to 205°C, then 700kg of 40 mesh rubber powder was added while stirring, heated to 260°C, stirred at constant temperature for 2.5 hours, cooled to 195°C, 500kg naphthenic oil was added, stirred for 10 minutes, and then 300kg SBS and 170kg SBR were added at 175°C Stir for 0.5 hour under conditions, then grind for 1 hour, then add 150kg hydrogenated petroleum resin, 750kg 200 mesh stone powder, 5kg ultraviolet absorber and 5kg antioxidant, and stir at 175℃ for 1.5 hours to obtain the prepared self-adhesive layer;

[0032] b. Preparation of asphalt layer: take 1100kg10 # Asphalt and 1100kg90 # After the asphalt is mixed, heat up to 195°C, add 700kg of 80 mesh nylon rubber powder, heat up to 255°C, stir at constant temperature for 1.5 hours, cool to 185°C, add 400kg minus three-line engine oil, mix well, add 150kg SBS, 80kg APP and 150kg at 175°C 120kgPP is oxidized for 2 hours, then ground for 1 hour,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com