Embedded double-fluid efficient energy-saving deamination system

A high-efficiency, energy-saving, dual-fluid technology, used in ammonia compounds, degassed water/sewage treatment, sustainable manufacturing/processing, etc. Solve the effect of large equipment footprint, low equipment processing capacity, and reduced wastewater treatment costs

Active Publication Date: 2014-10-08

JIANGSU HUASHAN ENVIRONMENTAL PROTECTION TECH

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing stripping process has many shortcomings, such as large equipment footprint and high energy consumption, especially in terms of steam unit consumption, resulting in high cost of ammonia nitrogen wastewater treatment, which makes enterprises unwilling or unable to bear the treatment costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0013] Adopt the present invention to treat ammonia nitrogen waste water import ammonia nitrogen concentration 3500mg / L, processing capacity 5t / h. Nessler's reagent colorimetric method (GB7479-87) was used for analysis, and the concentration of ammonia nitrogen in the treated wastewater was 12mg / L. The steam consumption is 35kg / t.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

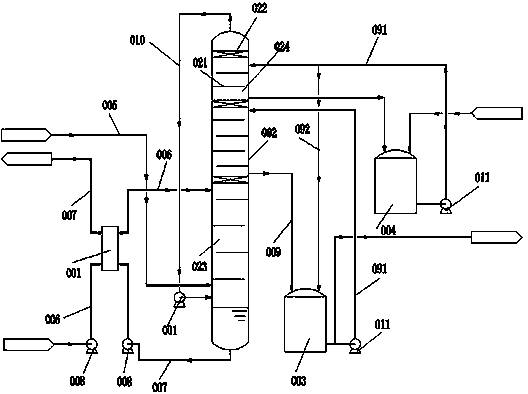

An embedded double-fluid efficient energy-saving deamination system belongs to the technical field of sewage processing. Equipment mainly comprises a lifting pump, a circulating pump, a heat exchanger, a flow-pushing pressurizing blower fan, and an embedded double-fluid efficient energy-saving deamination tower. In a technological process, ammonia-nitrogen wastewater subjected to heat exchanging enters the tower body, and subjected to deamination by flow-pushing pressurizing steam and fresh steam; and at the same time, ammonia-containing steam is absorbed by circulating ammonium sulfate and circulating dilute sulfuric acid and an ammonium sulfate solution is obtained, and purified steam is cycled for usage by a flow-pushing pressurizing kettle. The invention provides the ammonia-nitrogen wastewater processing equipment which is high in efficiency, low in steam consumption and small in occupied space, and also provides the ammonia-nitrogen wastewater processing technology.

Description

technical field [0001] The present invention relates to the field of manufacturing industrial wastewater separation equipment, in particular to a process technology involving the use of a tower-type steam push-flow pressurization and an embedded dual-fluid process technology to achieve simultaneous treatment and resource utilization of ammonia-nitrogen wastewater and recycling hot system. Background technique [0002] Ammonia nitrogen pollution is mainly caused when the concentration of ammonia nitrogen in the water body increases, which will lead to eutrophication of the water body and cause a large number of aquatic organisms to grow. When these organisms die, they are decomposed by microorganisms in the water and consume a lot of oxygen, resulting in severe hypoxia in the water, resulting in the death of a large number of aquatic organisms, and the corrupted water quality makes the microorganisms reproduce in large numbers, resulting in turbidity and stench in the water, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/20C01C1/242

CPCY02P20/10

Inventor 李祖华郭瀚程苏小明朱建平

Owner JIANGSU HUASHAN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com