A method for preparing building ceramic tiles by wet casting of granite waste

A granite waste, pouring and molding technology, applied in the field of architectural ceramics, to alleviate the increasing shortage problem, broad market prospects, strong noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

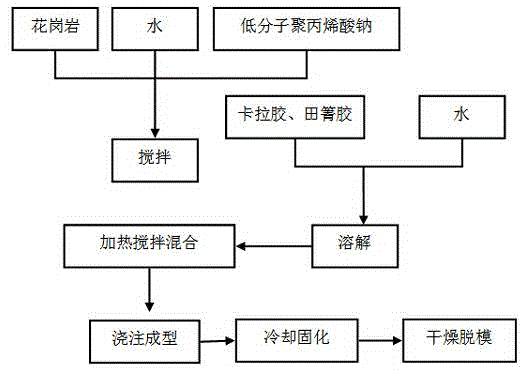

Method used

Image

Examples

Embodiment 1

[0018] First, the granite waste is ball-milled, dried, and passed through a 200-mesh sieve for later use. Then, according to the following slurry formula, add carrageenan and Tianqing gum to the mixed slurry of granite waste, water, and low-molecular-weight sodium polyacrylate. After dosing, heat and stir at 80°C for 60 minutes, inject it into a metal mold, put it into a drying oven and dry it at 60°C for 70 minutes after cooling, and then demould and dry. The measured green strength is 1MPa and the green density is 1.1 g / cm 3 , after demolding and drying the green body trimmed and fired at 1140°C, the measured flexural strength of the material was 56MPa.

[0019] The slurry formula is: 50wt% granite waste, 50wt% water, 1.0wt% carrageenan, 0.2wt% Tianqing gum, and 0.5wt% low molecular weight sodium polyacrylate.

Embodiment 2

[0021] First, the granite waste is ball-milled, dried, and passed through a 200-mesh sieve for later use. Then, according to the following slurry formula, add carrageenan and Tianqing gum to the mixed slurry of granite waste, water, and low-molecular-weight sodium polyacrylate. After dosing, heat and stir at 70°C for 65 minutes, pour it into a metal mold, put it in a drying oven at 50°C and dry for 80 minutes after cooling, and then demould and dry. The measured green strength is 1.2MPa and green density is 1.4g / cm 3 , after demoulding and drying the green body trimmed and fired at 1160°C, the measured flexural strength of the material was 60MPa.

[0022] The slurry formula is: 55wt% granite waste, 45wt% water, 1.3wt% carrageenan, 0.2wt% Tianqing gum, and 1wt% low molecular weight sodium polyacrylate.

Embodiment 3

[0024] First, the granite waste is ball-milled, dried, and passed through a 200-mesh sieve for later use. Then, according to the following slurry formula, add carrageenan and Tianqing gum to the mixed slurry of granite waste, water, and low-molecular-weight sodium polyacrylate. After dosing, heat and stir at 70°C for 70 minutes, inject it into a metal mold, put it in a drying oven and dry it at 70°C for 60 minutes after cooling, and then demould and dry. The measured green strength is 1.9MPa and green density is 1.6g / cm 3 , after demoulding and drying the green body trimmed and fired at 1180°C, the measured flexural strength of the material was 65MPa.

[0025] The slurry formula is: 60wt% granite waste, 40wt% water, 1.4wt% carrageenan, 0.4wt% Tianqing gum, and 1.5wt% low molecular weight sodium polyacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com