Water-based polyurethane adhesive and preparation method thereof

A water-based polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of low peel strength and low solid content of polyurethane adhesives, and achieve high peel strength , good fluidity and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides an aqueous polyurethane adhesive, which includes a prepolymer and water, and the prepolymer includes the following raw materials:

[0052] Polyester diol PBA2k, carboxylic acid type hydrophilic chain extender DMBA, diisocyanate IPDI, small molecule chain extender BDO and TEA, based on the molar ratio, IPDI: PBA: DMBA: BDO: TEA = 35: 10: 7.5:7.5:7.5.

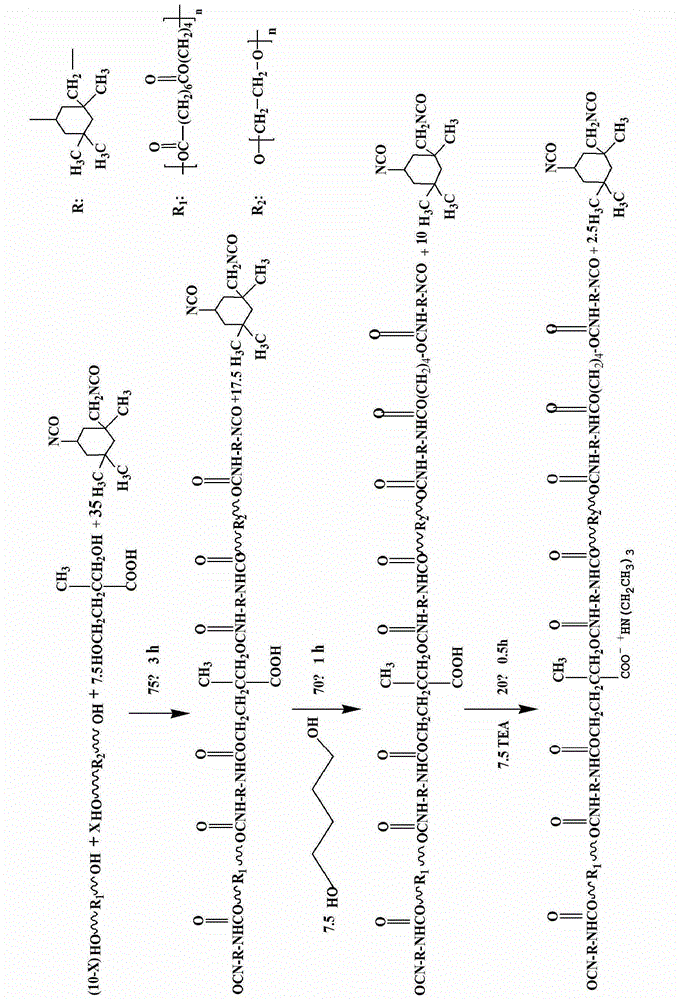

[0053] The water-based polyurethane adhesive of this embodiment is prepared by the following method, such as figure 1 Shown:

[0054] Heat 40gPBA2k to 120℃, dehydrate it for 30min, pour it into a 250ml three-necked flask equipped with a thermometer, reflux condenser and stirrer, keep it at 50℃, and then add 15.5gIPDI and 2.25gDMBA in acetone solution (in molar amount DMBA :Acetone=1:1), heat up to 75°C, stir and react at a constant speed for 3h to obtain the initial polymerization liquid;

[0055] Add 1.35g of BDO to the initial polymerization solution for chain extension and react at 70°C for 1 hour to o...

Embodiment 2

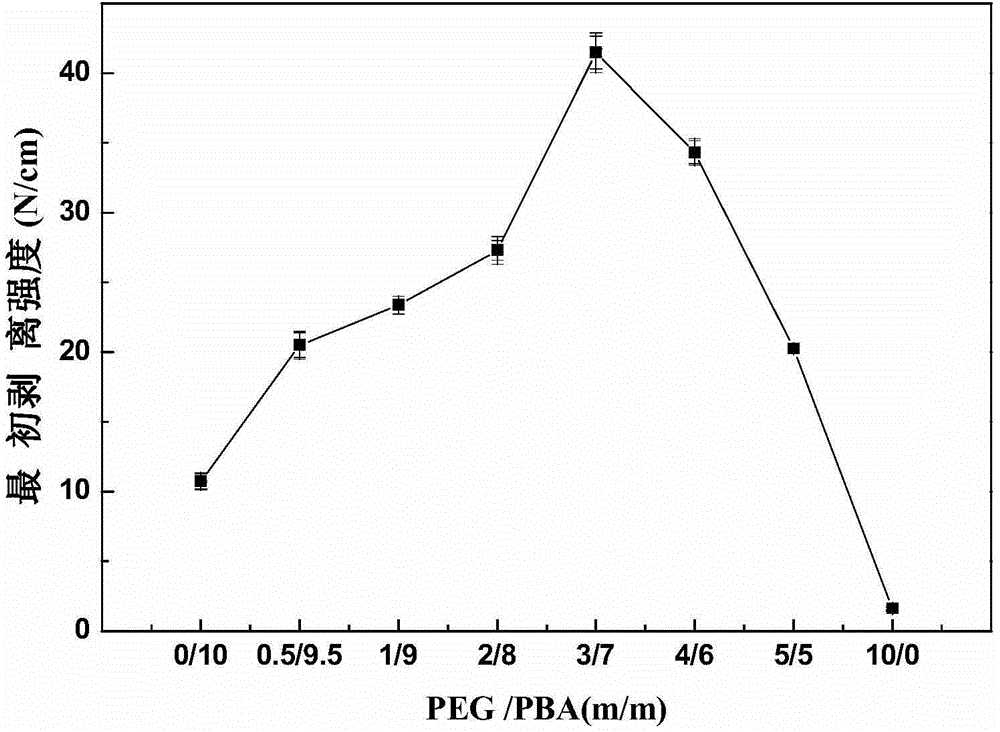

[0059] This embodiment provides an aqueous polyurethane adhesive, which includes a prepolymer and water, and the prepolymer includes the following raw materials:

[0060] Polyester diols PBA2k, PEG2k, carboxylic acid type hydrophilic chain extender DMBA, diisocyanate IPDI, small molecule chain extender BDO and TEA, in molar ratio, IPDI: PEG: PBA: DMBA: BDO: TEA = 35:0.5:9.5:7.5:7.5:7.5.

[0061] The water-based polyurethane adhesive of this embodiment is prepared by the following method, such as figure 1 Shown:

[0062] The 38gPBA2k and 2gPEG2k were heated to 120℃, dehydrated for 30min, poured into a 250ml three-necked flask equipped with a thermometer, reflux condenser and stirrer, kept at 50℃, and then added 15.5gIPDI and 2.25gDMBA in acetone solution (in molar amount Calculate DMBA: acetone=1:1), heat up to 75°C, stir and react at a constant speed for 3h to obtain the primary polymerization liquid;

[0063] Add 1.35g of BDO to the initial polymerization solution for chain extensio...

Embodiment 3

[0067] This embodiment provides an aqueous polyurethane adhesive, which includes a prepolymer and water, and the prepolymer includes the following raw materials:

[0068] Polyester diol PBA2k, PEG, carboxylic acid type hydrophilic chain extender DMBA, diisocyanate IPDI, small molecule chain extender BDO and TEA, in molar ratio, IPDI: PEG: PBA: DMBA: BDO: TEA = 35:1:9:7.5:7.5:7.5.

[0069] The water-based polyurethane adhesive of this embodiment is prepared by the following method, such as figure 1 Shown:

[0070] Heat 36gPBA2k and 4gPEG2k to 120°C, dehydrate for 30min, pour them into a 250ml three-necked flask equipped with thermometer, reflux condenser and stirrer, keep at 50°C, then add 15.5gIPDI and 2.25gDMBA in acetone solution (in molar amount Calculate DMBA: acetone=1:1), heat up to 75°C, stir and react at a constant speed for 3h to obtain the primary polymerization liquid;

[0071] Add 1.35g of BDO to the initial polymerization solution for chain extension and react at 70°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com