System for preparing colloidal crystal and method for preparing colloidal crystal

A colloidal crystal and injection system technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as limited growth area, long cycle, harsh growth conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

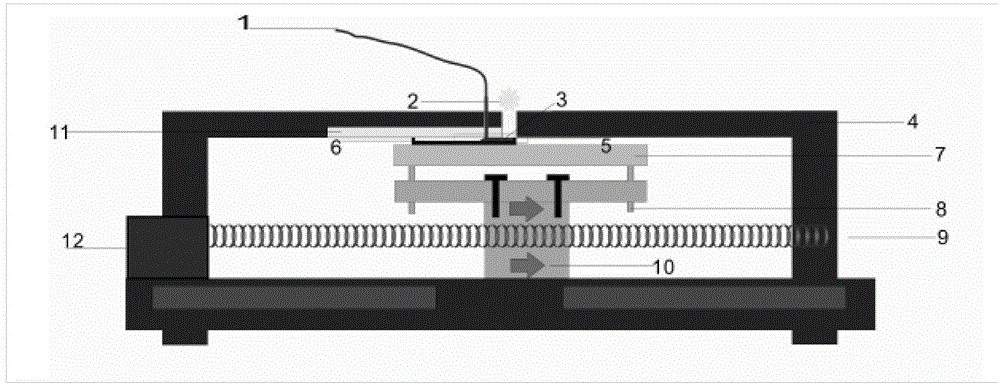

[0038] The present invention also provides a method for preparing colloidal crystals, the method comprising:

[0039] Step 1: prepare and clean the sample groove 6, fix the sample groove 6 on the metal platform 7, and align the right side of the sample groove 6 with the right side of the polytetrafluoroethylene plate 11;

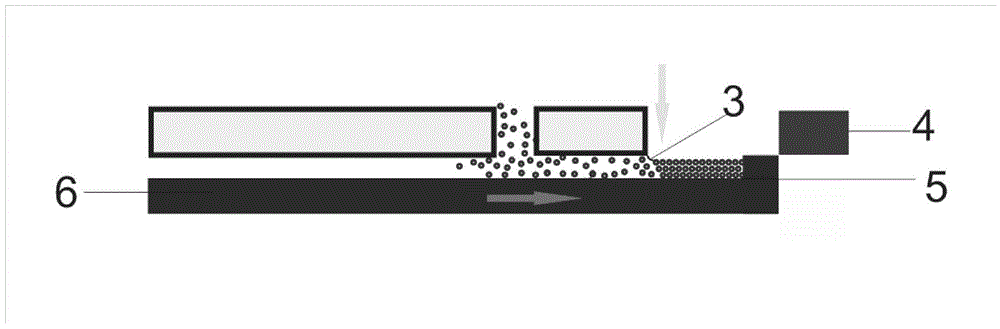

[0040] Step 2: Turn on the infrared wavelength heat source 2, and wait until the infrared wavelength heat source 2 reaches a stable state, preferably move the infrared wavelength heat source 2 to a distance of 10-15 cm from the sample groove, so that it can irradiate the polytetrafluoroethylene plate 11 and the sample groove 6 The meniscus 3 formed between; the infrared wavelength heat source is preferably an infrared evaporator;

[0041] Step 3: Inject the microsphere solution into the sample groove 6 through the microsphere injection system 1, so that the microsphere solution fills the gap between the sample groove 6 and the right side of the polytetrafluo...

Embodiment 1

[0051] Step 1: prepare and clean the sample groove 6, fix the sample groove 6 on the metal platform 7, and align the right side of the sample groove 6 with the right side of the polytetrafluoroethylene plate 11;

[0052] Step 2: Turn on the infrared evaporator 2, and when the infrared evaporator 2 reaches a stable state, move the infrared evaporator to a distance of 10-15 cm from the sample groove, so that it can irradiate between the PTFE plate 11 and the sample groove 6 The meniscus 3 formed;

[0053] Step 3: Inject 20ul of polystyrene microsphere solution with a concentration of 10% into the sample groove 6 at an injection rate of 5ul / min, so that the polystyrene microsphere solution fills the sample groove 6 and the polytetrafluoroethylene plate 11 side gaps;

[0054] Step 4: Turn on the driving motor 12, and the driving motor 12 drives the threaded shaft 9 to drive the metal moving module 10 to move to the right, and at the same time inject polystyrene solution into the ...

Embodiment 2

[0059] The difference from Example 1 is that the injection rate is set to 15ul / min, and the rest of the steps and conditions are the same as in Example 1.

[0060] Experimental results show that when the injection rate is 15ul / min, the integrity of the ordered colloidal crystal sample formed by the present invention is better, and there are fewer cracks on the sample surface, which is less different from the colloidal crystal sample in Example 1. Figure 6 The SEM image of the surface of the colloidal crystals prepared in Example 2 of the present invention shows that the polystyrene microspheres of the present invention are regularly arranged and have a high degree of order.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com