An experimental simulation device and method for exploiting natural gas hydrate

A technology of experimental simulation and hydrate, which is applied in the direction of mining fluid, gas fuel, earth drilling, etc., can solve the problems of low replacement efficiency, slow replacement rate, hydrate decomposition, etc., and achieve low cost, prevention of decomposition, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

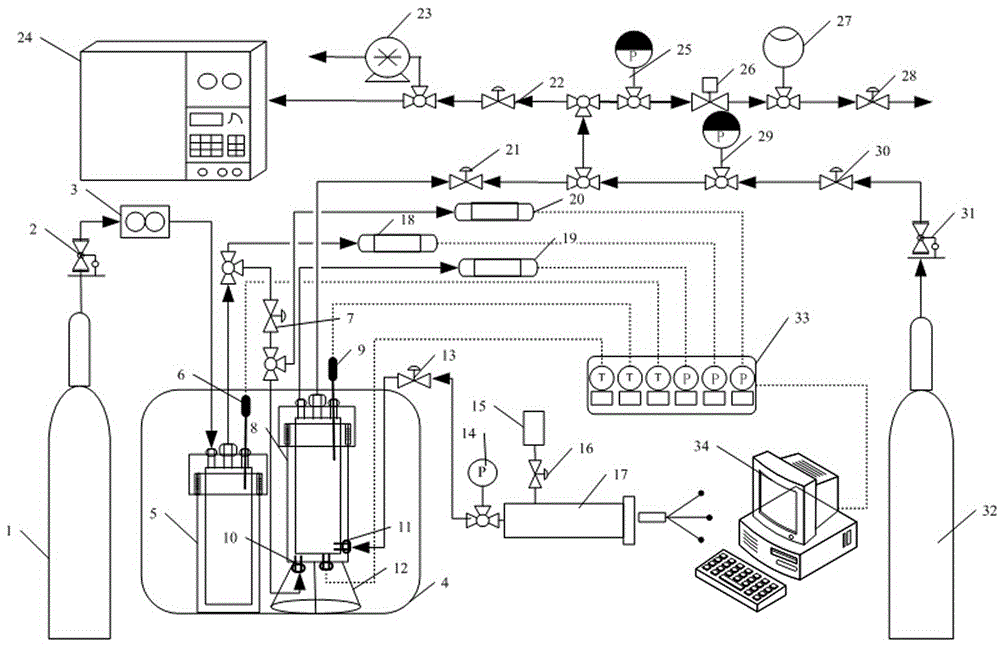

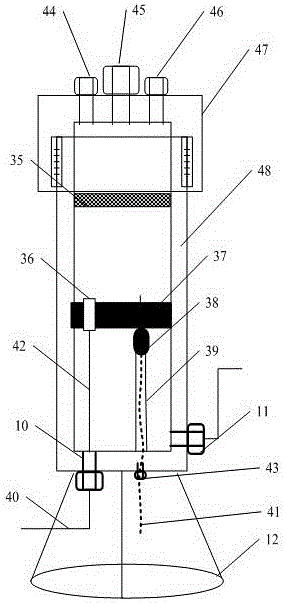

[0038] Such as figure 1 As shown, an experimental simulation device for exploiting natural gas hydrate, including a stable pressure gas supply and liquid supply module, a reactor 8, a control module, a data measurement module, and a data acquisition and processing module, wherein:

[0039] The reactor 8 includes a kettle body 48, a piston 37 that is sealed and can move up and down with the inner wall of the kettle body 48, a kettle cover 47 that is connected to the top of the kettle body 48, and supports a support 12 that is arranged at the bottom of the kettle body 48. The kettle lid 47 is provided with a pressure detection interface 44, a gas inlet and outlet 45, and a temperature detection interface 46 that can be connected to the inner cavity of the kettle body 48. The end of the inner cavity of the kettle body 48 near the kettle lid 47 is equipped with a microporous filter 35 , to achieve uniform distribution of pressure, the piston 37 is provided with a third temperature...

Embodiment 2

[0047] A method of producing natural gas hydrates, comprising the steps of:

[0048] (1) Generate hydrate: place the piston 37 at the bottom of the reactor 8, add a certain amount of sodium lauryl sulfate solution into the reactor 8, vacuumize, open the fourth valve 21, the seventh valve 30, and Reactor 8 is filled with CH 4 To a pressure of 4MPa, adjust the temperature of the constant temperature tank 4, under the conditions of a temperature of 1°C and a pressure of 4MPa, the reaction time is 100h to form a hydrate;

[0049] (2) CO 2 Reserve: when generating hydrate, close the first valve 7, 2 The gas is charged into the buffer tank 5, and the volume of the buffer tank 5 is 100ml, and the CO entering the buffer tank 5 is measured with a mass flow meter 3 2 amount;

[0050] (3) Isobaric exhaust: After the hydrate is formed, open the second valve 13 and the third valve 16, and use the hand pump 17 to inject a certain mass fraction of brine into the bottom of the reactor 8 f...

Embodiment 3

[0059] A method of producing natural gas hydrates, comprising the steps of:

[0060] (1) Generate hydrate: place the piston 37 at the bottom of the reactor 8, add a certain amount of sodium lauryl sulfate solution into the reactor 8, vacuumize, open the fourth valve 21, the seventh valve 30, and Reactor 8 is filled with CH 4 To a pressure of 8MPa, adjust the temperature of the constant temperature tank 4, under the conditions of a temperature of 6°C and a pressure of 8MPa, the reaction time is 50h to form a hydrate;

[0061] (2) CO 2 Reserve: when generating hydrate, close the first valve 7, 2 The gas is charged into the buffer tank 5, and the volume of the buffer tank 5 is 500ml, and the CO entering the buffer tank 5 is measured with a mass flow meter 3 2 amount;

[0062] (3) Isobaric exhaust: After the hydrate is formed, open the second valve 13 and the third valve 16, and use the hand pump 17 to inject a certain mass fraction of brine into the bottom of the reactor 8 from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com