Diesel engine bearing cover

A diesel engine, bearing cap technology, applied in engine components, machines/engines, bearing components, etc., can solve the problems of affecting the service life of the internal bearings of the engine, inconvenient to add lubricating oil, etc., to achieve simple structure, good lubrication, and prevent impurities. effect of entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

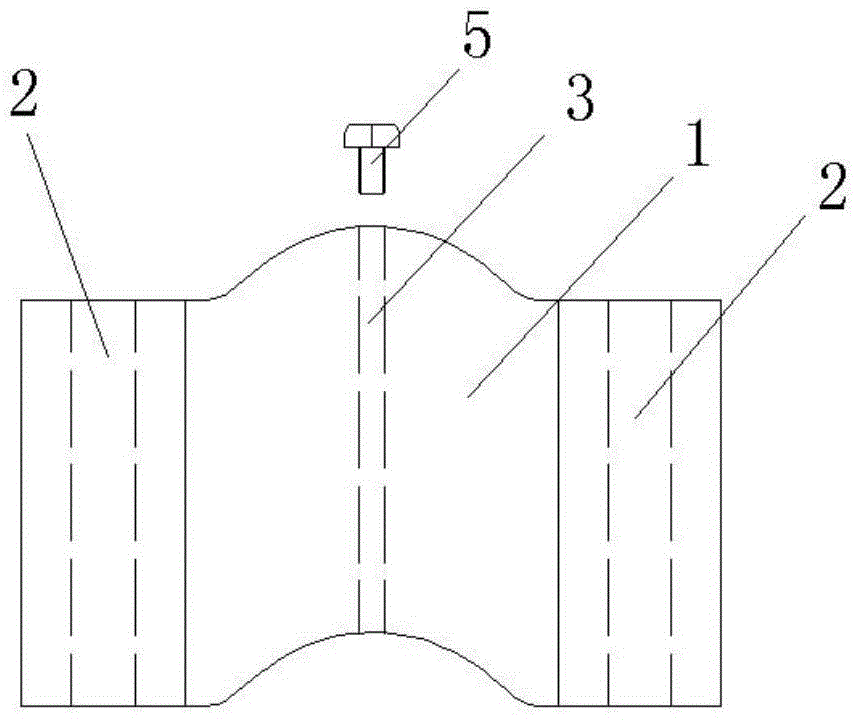

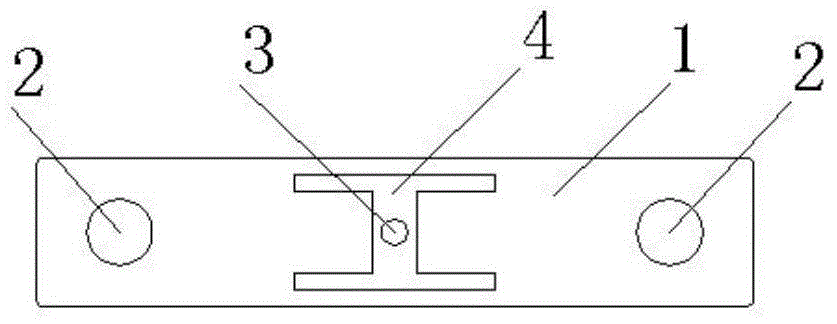

[0011] Example: such as figure 1 , figure 2 As shown, the diesel engine bearing cap of the present invention has an oil filling hole 3 in the middle part of the bearing cap 1, and there are installation and fixing holes 2 on both sides of the bearing cap 1, which are used to fix the bearing cap 1 on the cylinder head, so that The camshaft rotates at high speed in the bore formed by the bearing cap and the cylinder head. The high-speed rotation of the camshaft requires lubricating oil. There is an H-shaped oil groove 4 on the semicircular inner wall of the bearing cover 1, and the oil filling hole 3 is connected to the center of the H-shaped oil groove 4, so that the lubricating oil flows into the H-shaped oil groove 4 through the oil filling hole 3, and then passes through the H-shaped oil groove 4. The oil groove 4 makes the lubricating oil evenly distributed to the camshaft to form a lubricating oil film, forming good lubrication in the wide range of the journal, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com