Method for detecting contents of potassium carbonate and potassium bicarbonate in desulfuration solution

A desulfurization solution, potassium bicarbonate technology, applied in the direction of material electrochemical variables, etc., can solve the problems of time-consuming, complicated operation, multi-chemical reagents, etc., and achieve the effect of simple operation, high accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

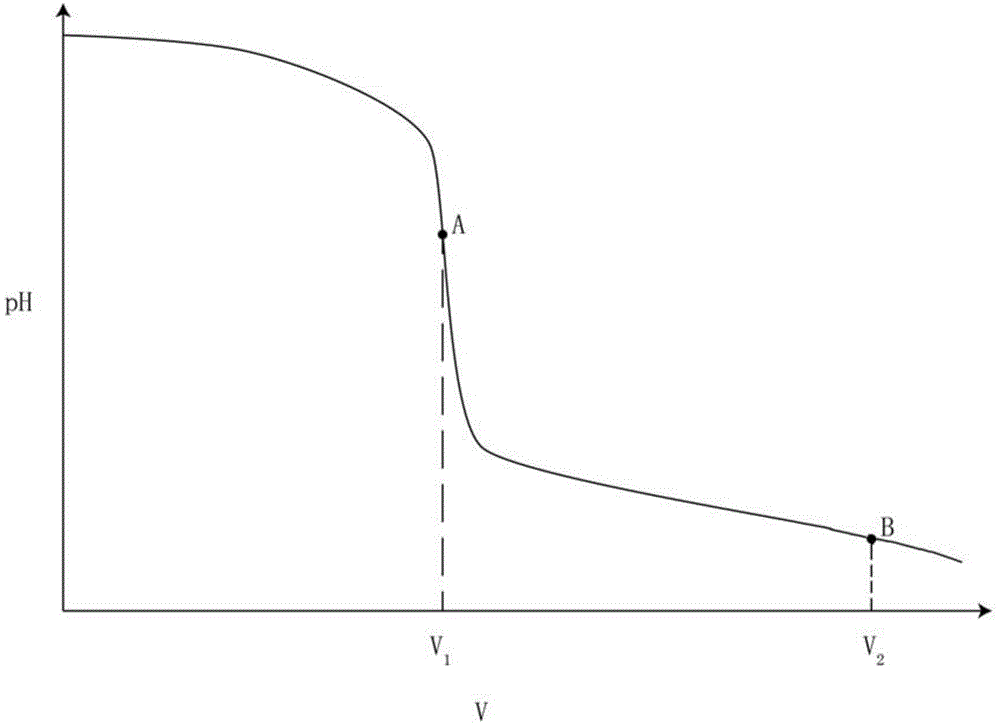

Method used

Image

Examples

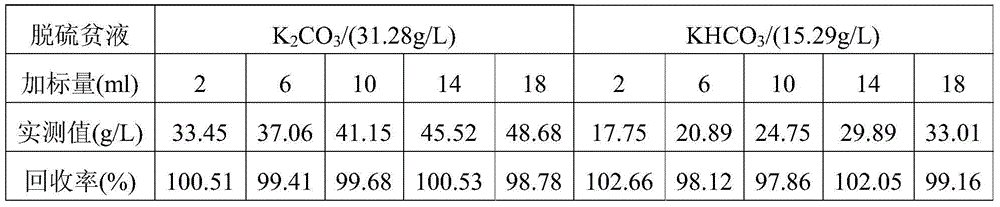

example 1

[0039] (1) Instruments and reagents used

[0040] Instrument: ZDJ-4A type automatic potentiometric titrator, E-201-C-9 type pH composite electrode.

[0041] Reagent: hydrochloric acid standard solution, c(HCl)=0.2000mol / L; standard buffer solution with pH 4.0 and 6.864.

[0042] (2) Calibration

[0043] First, start the automatic potentiometric titrator and preheat it for more than 10 minutes to make it stable.

[0044] Then, use a standard buffer solution with a pH of 6.864 for positioning, then use a standard buffer solution with a pH of 4.0 for positioning, and then use a standard buffer solution with a pH of 6.864 for positioning, so that the value displayed by the instrument is consistent with the pH value of the buffer solution .

[0045] (3) Determination

[0046] Prepare the sample solution: Measure 5ml of the desulfurization solution sample with a pipette and place it in a 100ml beaker, add CO2-free 2 Dilute to 30ml with distilled water, and place the beaker on t...

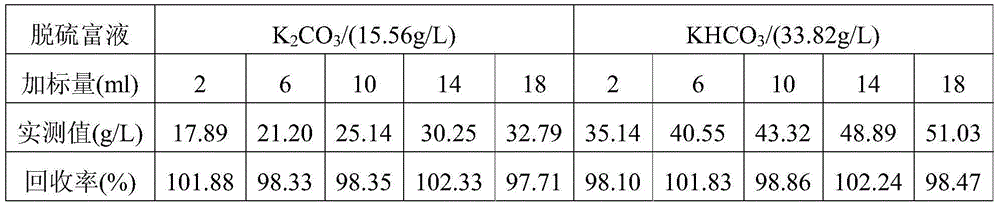

example 2

[0051] (1) Instruments and reagents used

[0052] Instrument: ZDJ-4A type automatic potentiometric titrator, E-201-C-9 type pH compound electrode.

[0053] Reagent: hydrochloric acid standard solution, c(HCl)=0.1000mol / L; standard buffer solution with pH 4.0 and 6.864.

[0054] (2) Calibration

[0055] First, start the automatic potentiometric titrator and preheat it for more than 10 minutes to make it stable.

[0056] Then, use a standard buffer solution with a pH of 6.864 for positioning, then use a standard buffer solution with a pH of 4.0 for positioning, and then use a standard buffer solution with a pH of 6.864 for positioning, so that the value displayed by the instrument is consistent with the pH value of the buffer solution .

[0057] (3) Determination

[0058] Prepare the sample solution: Measure 5ml of the desulfurization solution sample with a pipette and place it in a 100ml beaker, add CO2-free 2 Dilute to 50ml with distilled water, and place the beaker on th...

example 3

[0063] (1) Instruments and reagents used

[0064] Instrument: ZDJ-4A type automatic potentiometric titrator, E-201-C-9 type pH composite electrode.

[0065] Reagent: hydrochloric acid standard solution, c(HCl)=0.5000mol / L; standard buffer solution with pH 4.0 and 6.864.

[0066] (2) Calibration

[0067] First, start the automatic potentiometric titrator and preheat it for more than 10 minutes to make it stable.

[0068] Then, use a standard buffer solution with a pH of 6.864 for positioning, then use a standard buffer solution with a pH of 4.0 for positioning, and then use a standard buffer solution with a pH of 6.864 for positioning, so that the value displayed by the instrument is consistent with the pH value of the buffer solution .

[0069] (3) Determination

[0070] Prepare the sample solution: Measure 5ml of the desulfurization solution sample with a pipette and place it in a 100ml beaker, add CO2-free 2 Dilute to 40ml with distilled water, and place the beaker on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com