Inductance structure and method for making same

A manufacturing method and inductance technology, applied in the direction of inductors, circuits, electrical components, etc., can solve the problem that the performance of planar inductance needs to be further improved, and achieve the effect of reducing eddy current, improving performance, and improving Q value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

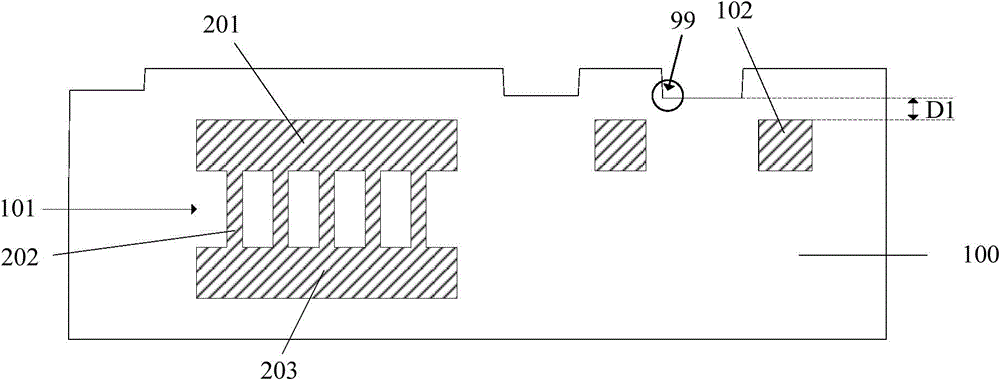

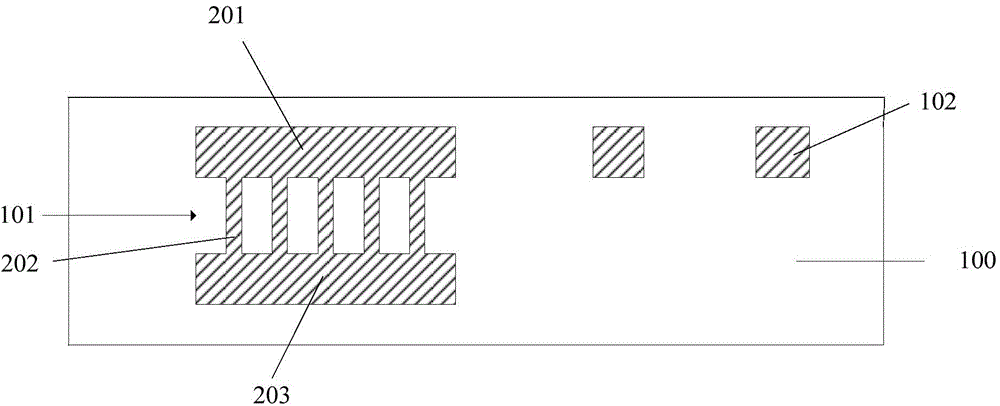

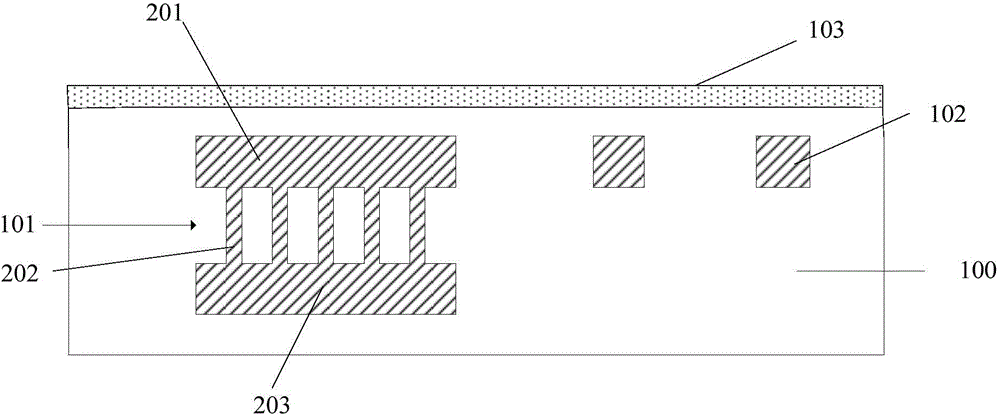

[0034] In the prior art, the inductance value of the inductance can be increased by arranging magnetic materials inside the inductance coil. However, the method of arranging magnetic materials inside the inductance coil to increase the inductance value of the inductance may generate magnetic The residue of the material and the residue of the magnetic material are in the shape of a ring, which may generate a large eddy current when the inductance coil is working, which increases the energy loss of the inductance coil and reduces the Q value of the inductance. The Q value of the inductance is also called the quality factor of the inductance, which is the main parameter to measure the inductance device. It refers to the ratio of the inductive reactance presented by an inductor to its equivalent loss resistance when it operates under an AC voltage of a certain frequency. The higher the Q value of the inductor, the smaller the loss and the higher the efficiency.

[0035] In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com