Etching liquid for forming texture

A technology of etching liquid and texture, which is applied in the field of etching liquid, and can solve the problem that the etching liquid cannot be as it is.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

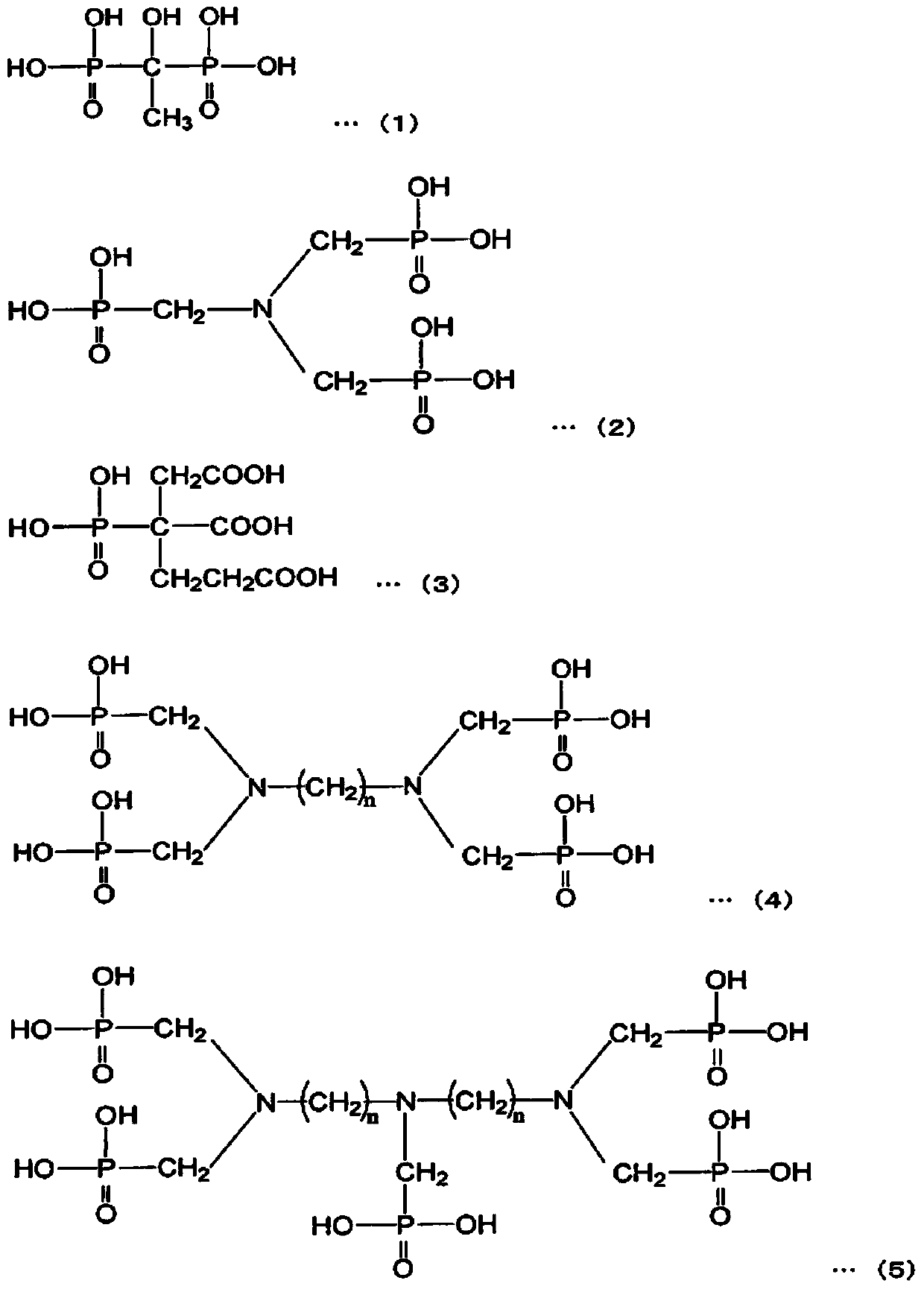

Method used

Image

Examples

Embodiment

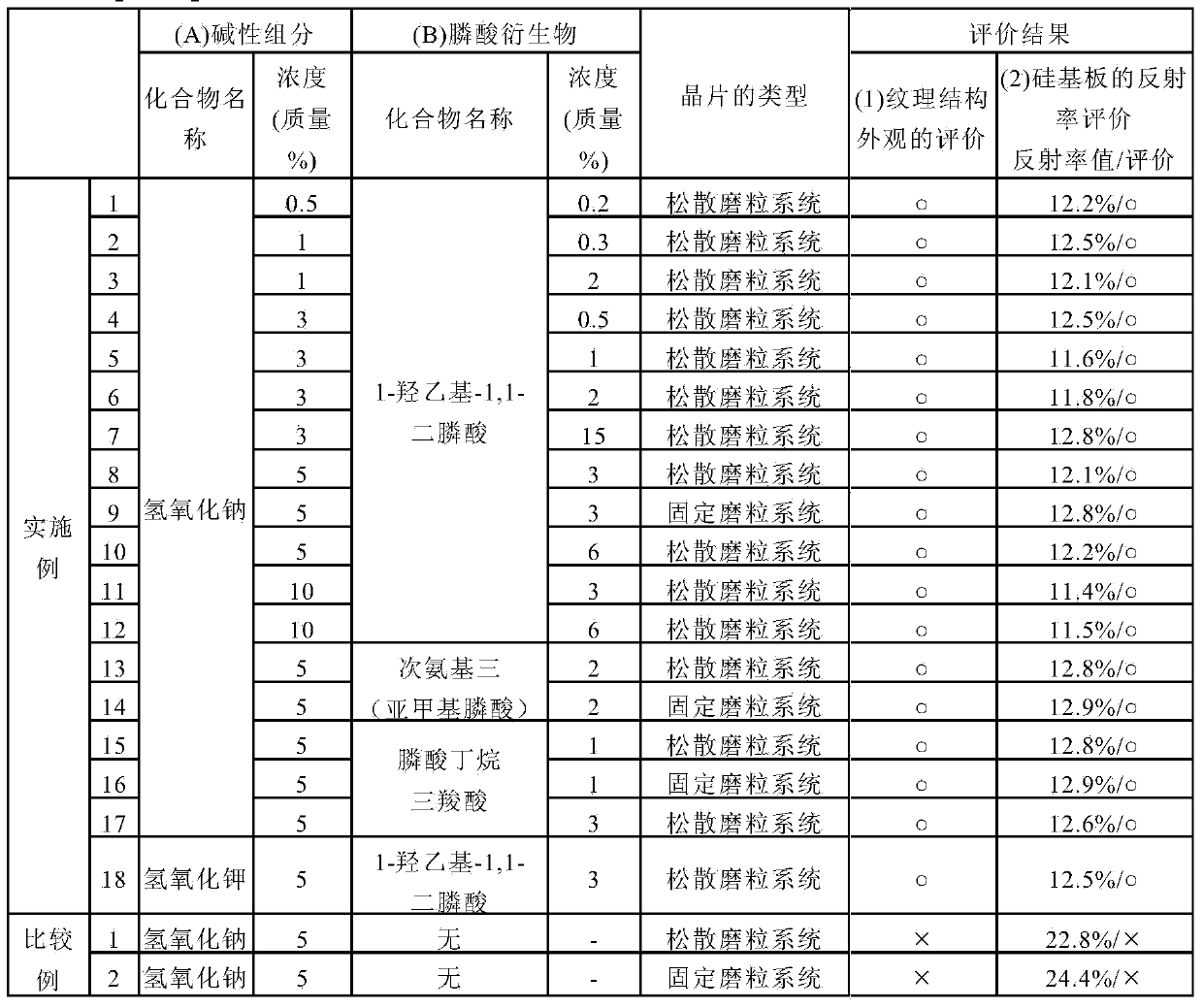

[0042] The present invention is described more specifically based on examples. However, the present invention is not limited to the following examples.

[0043] [Example, comparative example]

[0044] Sodium hydroxide and a phosphonic acid derivative or a salt thereof were mixed at a ratio shown in Table 1, and then ion-exchanged water was added to prepare an aqueous solution. It is the etching solution of the present invention. The etchant was heated to 80° C., and a single crystal silicon wafer cut using any of the loose abrasive systems or fixed abrasive systems shown in Table 1 was immersed in the etchant for 20 minutes, then washed with water and dried. The texture structure of the obtained silicon wafer was evaluated by the following two items.

[0045] (1) Appearance evaluation of texture structure

[0046]The texture structure was observed by using a scanning electron microscope (JEOL's JSM-6380LV). Observed under 1000 times magnification, the surface of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com