Transfer faction solution and preparation method thereof

A transfer factor and solution technology, which is applied in the field of transfer factor solution and its preparation, can solve the problems of low content, low yield of transfer factor solution, and high content of polymer substances, so as to improve product yield, increase stability and safety , the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

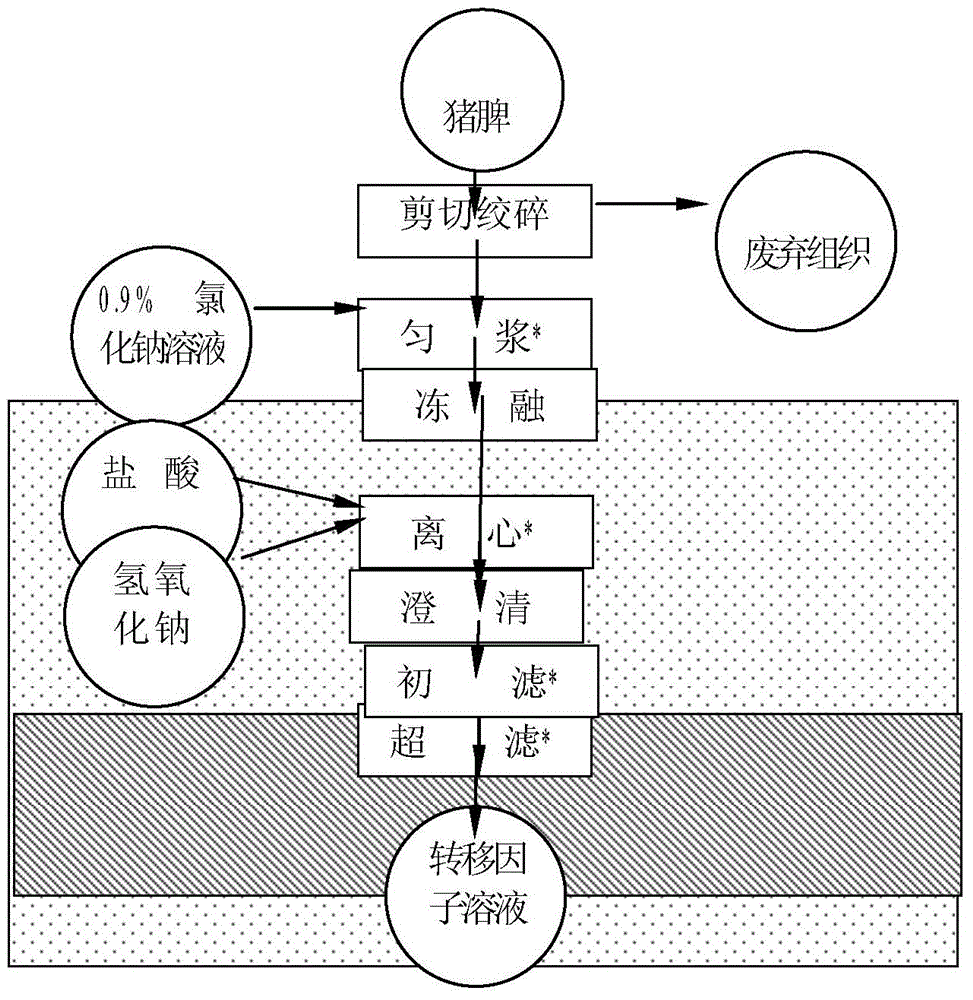

[0021] The preparation method of transfer factor solution (see figure 1 ):

[0022] Rinse the thawed pig spleen with purified water, remove the fat, cut off the connective tissue, put it into a meat grinder, and mince it (2-3mm) for later use.

[0023] The minced spleen is mixed with 0.9% NaCl (W / V) (W / V, mass volume ratio) solution at a weight ratio of 1:1.3, and then added to a colloid mill to grind for 1 to 2 minutes to obtain a uniform Slurry, wherein the gap of the colloid mill is 5-10um.

[0024] The homogenate was subjected to repeated freezing and thawing for 5 times. After freezing and thawing, use 2mol / L HCL solution to mix the homogeneous slurry to a pH value of 4.0, and then centrifuge at a speed of 2000 rpm for 30 minutes to collect the supernatant. L of NaOH solution to adjust the pH value to 7.0, adjust the pH value and then filter. After filtration, the filtrate is ultra-filtered through a hollow fiber column, and the filtrate is the transfer factor solution....

Embodiment 2

[0028] The preparation method of transfer factor solution (see figure 1 ):

[0029] Rinse the thawed pig spleen with purified water, remove the fat, cut off the connective tissue, put it in a meat grinder, and grind it for use.

[0030] After mincing, the spleen is mixed with 0.9% NaCl solution at a weight ratio of 1:1.4, and then added to a colloid mill to grind for 1 to 2 minutes to obtain a homogenate. Among them, the gap of the colloid mill is 5-10um.

[0031] The homogenate was subjected to repeated freezing and thawing for 5 times. After freezing and thawing, use 2mol / L HCL solution to mix the homogeneous slurry to a pH value of 4.0, then centrifuge at a speed of 2500 rpm for 20 minutes, collect the supernatant, and then pass the supernatant through 2mol / L The NaOH solution of 1 L adjusts the pH value to 7.0, and filters after adjusting the pH value. After filtration, the filtrate is ultra-filtered through a hollow fiber column (pressure is controlled at 0.1-0.2Mpa), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com