Natural fiber fabric inkjet printing thermal transfer paper and preparation method thereof

A technology of inkjet printing and natural fiber, which is applied in the direction of surface covering paper, decorative art, and technology for producing decorative surface effects, etc. It can solve the problems of difficult peeling of transfer paper and fabric, hardening of fabric feel, etc., and achieve color Vibrant, easy-to-use, image-clear results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

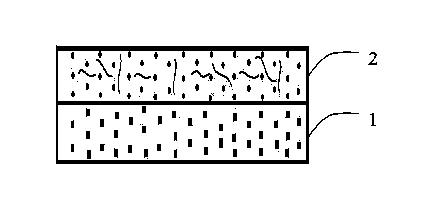

Image

Examples

Embodiment 1

[0044] raw material weight

[0045] CaCO 3 1g;

[0046] Na 2 CO 3 1g;

[0047] NaOH 1g;

[0048] PEG 7g;

[0049] CMC 30g;

[0050] PU emulsion 30g;

[0051] 30g of water.

Embodiment 2

[0053] raw material weight

[0054] Starch 2g;

[0055] Na 2 CO 3 3g;

[0056] PEG 6g;

[0057] Glycerin 2g;

[0058] Sodium alginate 30g;

[0059] PA emulsion 10g;

[0060] PU emulsion 25g;

[0061] 22g of water.

Embodiment 3

[0063] raw material weight

[0064] MgO 1g;

[0065] Starch 1g;

[0066] NaOH 1g;

[0067] NaHCO 3 2g;

[0068] Propylene glycol 1g;

[0069] Urea 10g;

[0070] Guar gum 20g;

[0071] CMC 5g;

[0072] PE emulsion 10g;

[0073] PU powder 15g;

[0074] 24g of water.

[0075] It should be noted that the three examples provided here list each component in the form of specific weight. It can be easily understood that the weight of each component can be obtained according to the weight of each component given. Weight ratio, these all should belong to the category of technical spirit of the present invention. Further introduce the preparation method of above-mentioned thermal transfer paper below, it comprises the following steps:

[0076] (1) The preparation quantity is 120g / m 2 Neutral paper is used as the base paper, and its water absorption value is 22g / m 2 ;

[0077] (2) Dissolving the hot-melt adhesive powder, penetrating agent, alkal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com