Parking craning method for vibration sinking construction of steel cylinders

A technology of steel cylinder and sinking block, which is applied in the field of lifting objects, can solve the problems of space constraints and difficulties in positioning of floating cranes and positioning barge, and achieve convenient and concise lifting process, speed up lifting progress, and improve The effect of lifting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

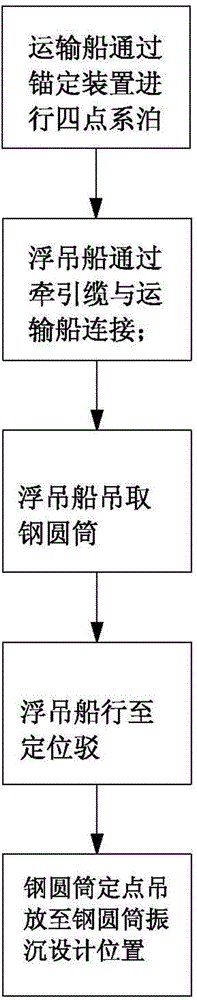

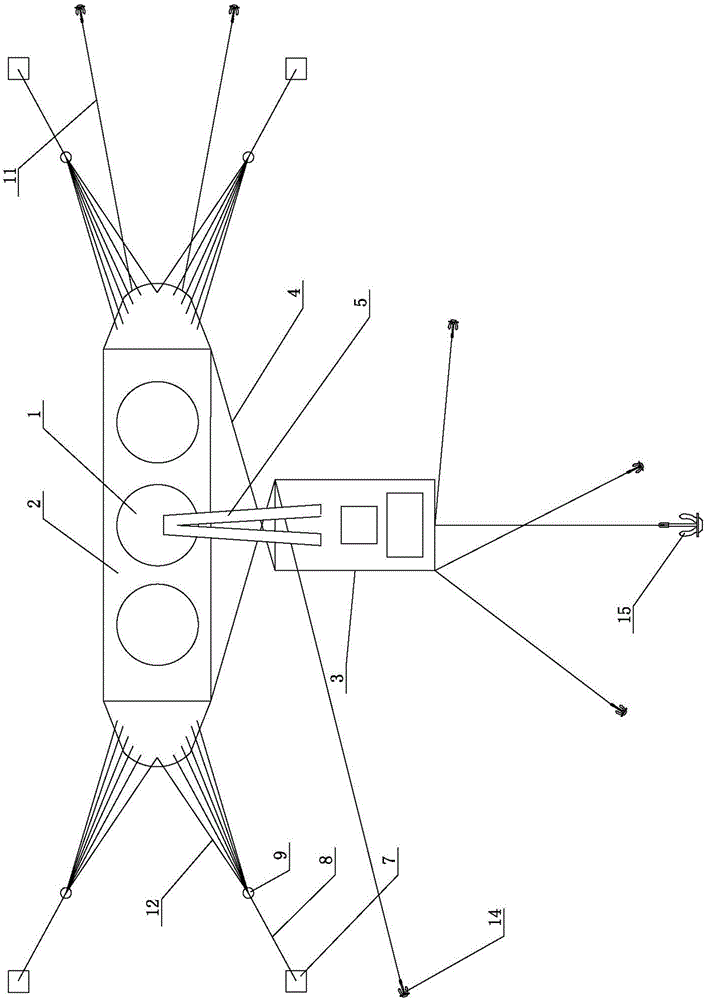

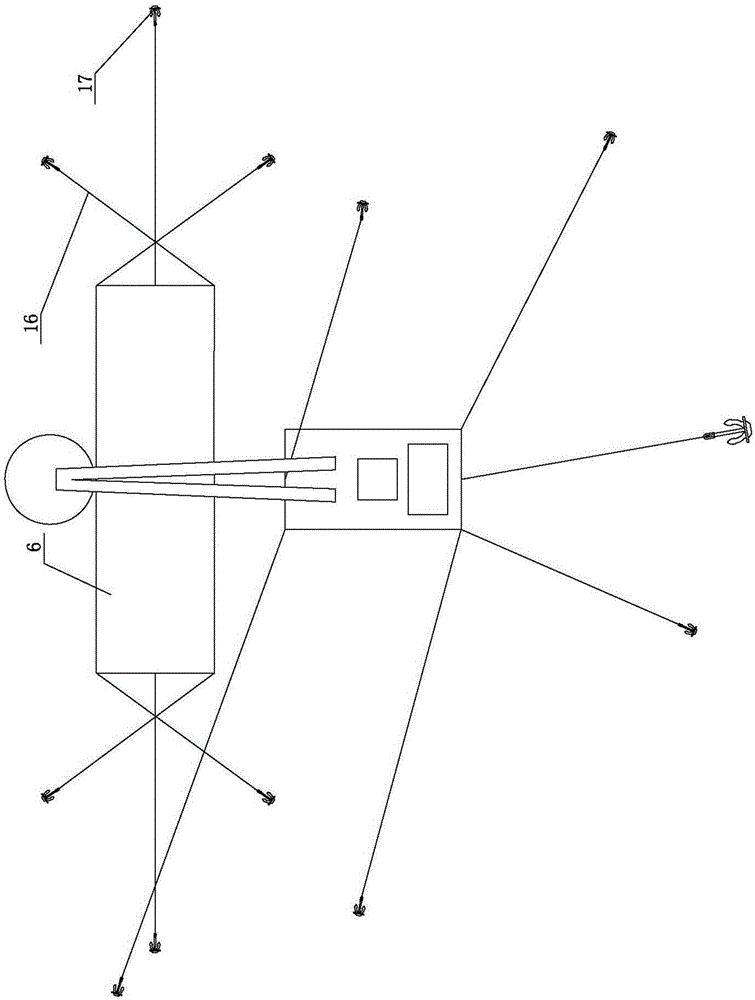

[0028] see figure 1 , figure 2 , image 3 Shown, a kind of steel cylinder vibratory sinking construction of the present invention is stationed hoisting method, comprises the following steps:

[0029] 1. After the transport ship 2 carrying the steel cylinder 1 arrives at the station, four-point mooring is carried out to the transport ship through the anchoring device;

[0030] 2. The floating crane ship 3 travels to the lifting position on the side of the transport ship and anchors it for positioning. The bow of the floating crane ship is connected to the bow and stern of the transport ship through two cross-set towing cables 4 and other anchors to hoist and hold the position. ; And control the retraction of the traction cable by the winch (belonging to the prior art, not shown in the figure) for retracting the traction cable on the floating crane ship, so as to realize the displacement and steering of the floating crane.

[0031] The method of the present invention adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com