Liquid crystal alignment agent, liquid crystal alignment film, liquid crystal display element and manufacturing method thereof

A liquid crystal alignment agent and liquid crystal alignment technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of inability to obtain uniform and good liquid crystal alignment film, uneven film development of alignment agent, poor solubility, etc., and achieve excellent Effects of display quality, improved coatability, and good pretilt angle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1 and

[0078] Synthesis Example 1 and Synthesis Example 2

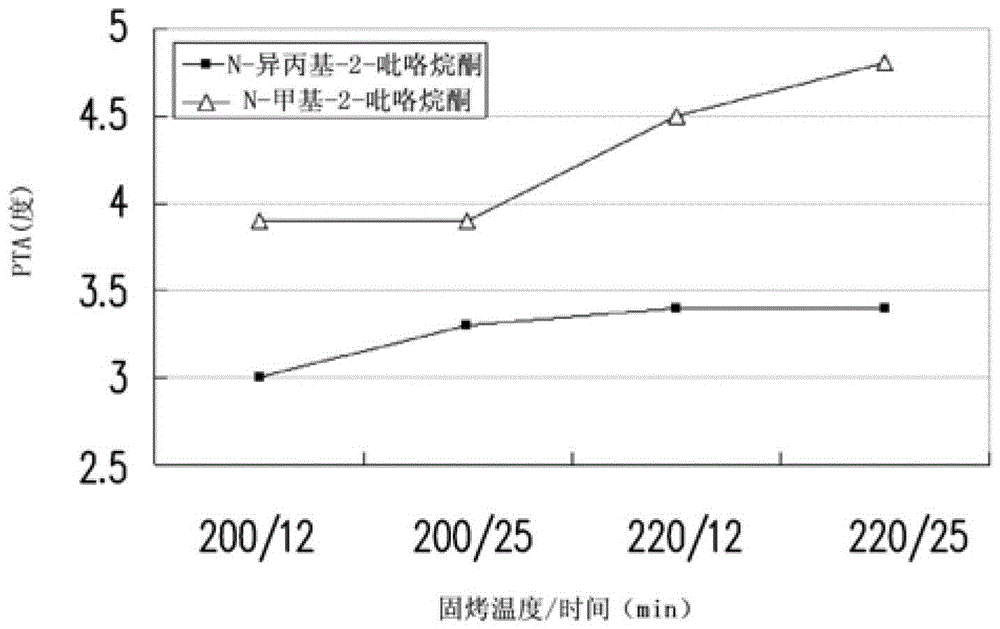

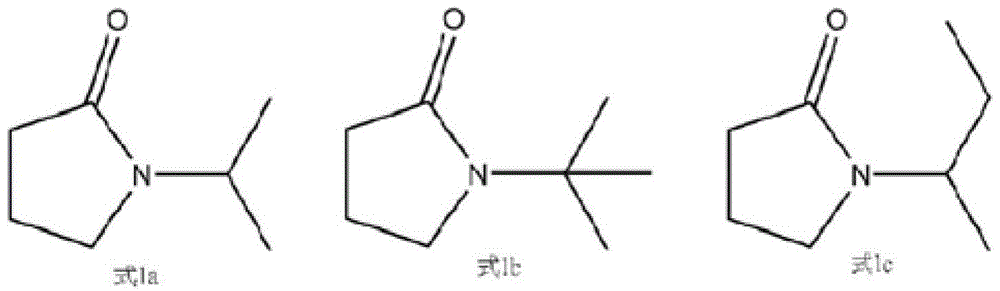

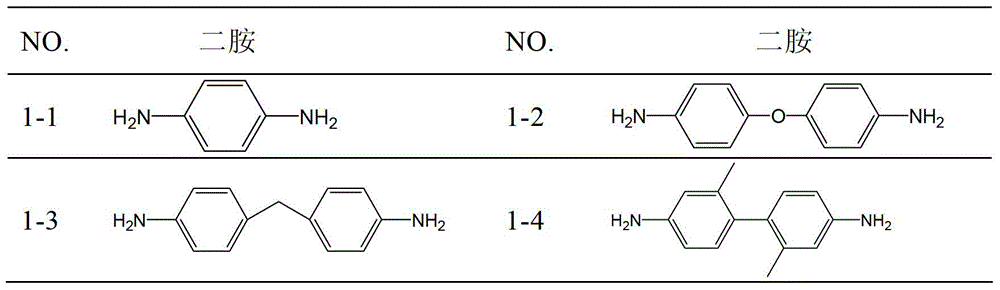

[0079] Add diamine and tetracarboxylic dianhydride to N-methyl-2-pyrrolidone in sequence (its chemical structure and weight are shown in Table 1 and Table 3) to prepare a solution with a solid content of 20% by weight, and in React at 40°C to 60°C for 4 hours to 6 hours to obtain a polyamic acid polymer, and then purify it with a solvent (such as methanol or water) with poor solubility for the polyamic acid polymer, and by reducing Drying under pressure gave Polymer A1 and Polymer A2.

Synthetic example 3 and

[0080] Synthesis Example 3 and Synthesis Example 4

[0081] Add diamine and tetracarboxylic dianhydride to N-isopropyl-2-pyrrolidone in sequence (its chemical structure and weight are shown in Table 1 and Table 3) to prepare a solution with a solid content of 20% by weight, and React at 40°C to 60°C for 4 hours to 6 hours to obtain a polyamic acid polymer, and then purify it with a solvent (such as methanol or water) that has poor solubility for the polyamic acid polymer, and by reducing Drying under pressure gave Polymer A3 and Polymer A4.

Synthetic example 5

[0083] Sequentially add diamine and tetracarboxylic dianhydride to N-methyl-2-pyrrolidone (as shown in Table 3) to prepare a solution with a solid content of 20% by weight, and store at 40°C to 60°C React for 4 hours to 6 hours to obtain a polyamic acid polymer, then add pyridine and acetic anhydride to the obtained polyamic acid polymer (the amount depends on the polyimidization ratio), at 100°C to 110°C The dehydration / ring-closing reaction was carried out at C for 3 hours to 4 hours, and the resulting solution was precipitated with methanol, purified with methanol, and finally collected and dried under reduced pressure to obtain polymer B1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com