Combination of platinum compound and carbon black to formulate flame retardant rubber compound

A technology of platinum compound and rubber mixing, which is applied in the field of rubber products, can solve the problems of poor performance of flame retardant mixing silicone rubber, and achieve the effects of good flame retardant performance, convenient preparation and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

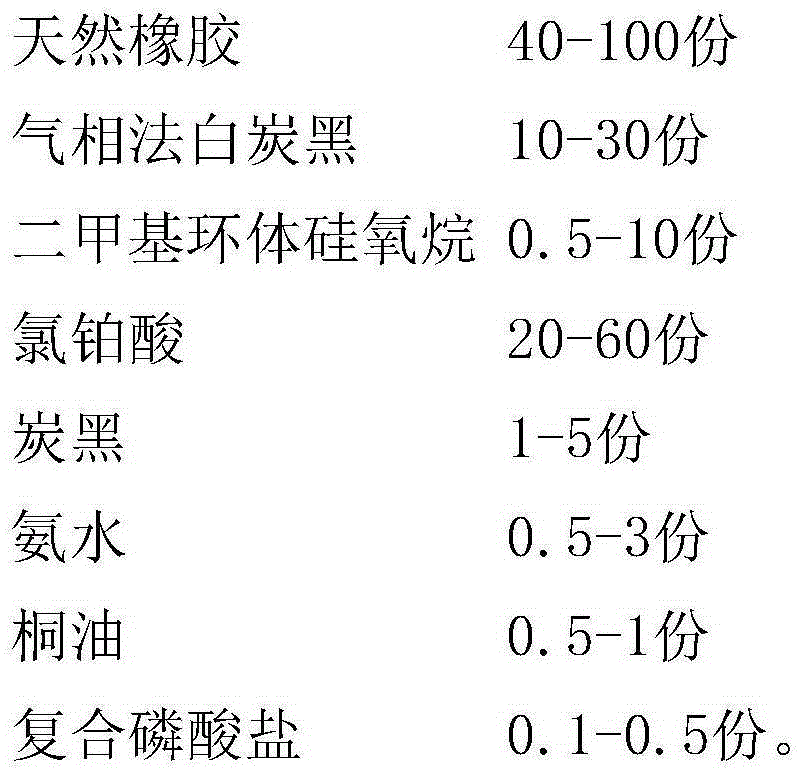

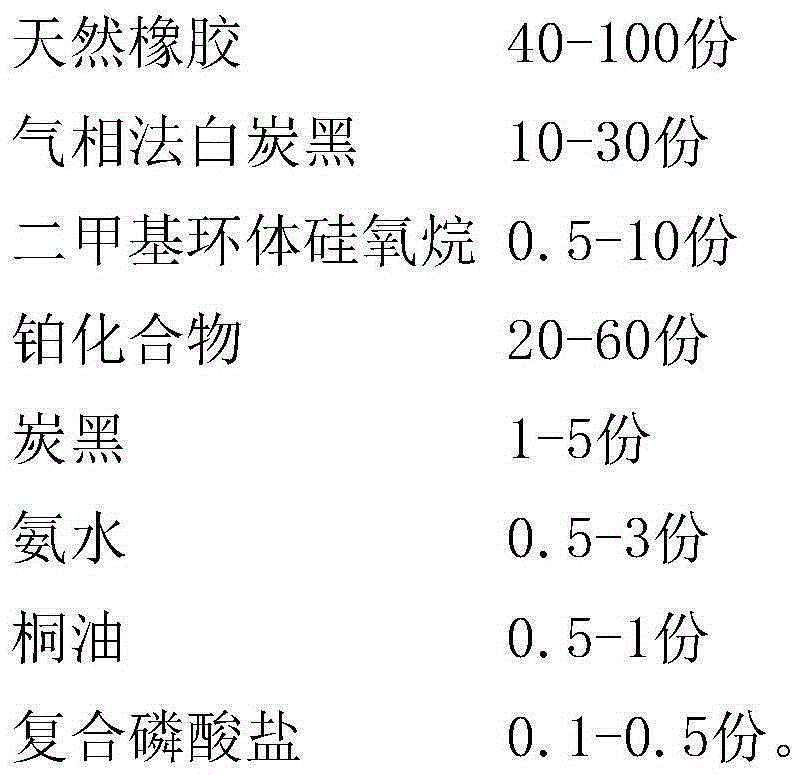

[0014] A platinum compound combined with carbon black to formulate a flame retardant rubber compound consisting of components by weight of,

[0015]

[0016]

[0017] The platinum compound is chloroplatinic acid.

[0018] Its method steps are as follows,

[0019] a. Add fumed silica and dimethylcyclosiloxane to natural rubber, knead evenly in a kneader, treat at 140-170°C for 1-4 hours, then add platinum compound and mix well, Formulated with glue;

[0020] b. Mix the rubber material with carbon black, ammonia water, tung oil and compound phosphate on a double-roller rubber mixer to make a flame-retardant mixed silicone rubber.

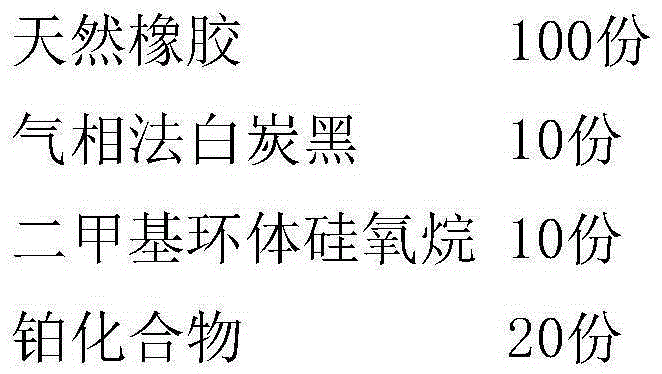

Embodiment 2

[0022]

[0023] The platinum compound is chloroplatinic acid.

[0024] A method for preparing flame-retardant mixed rubber with platinum compound and carbon black, characterized in that: the method steps are as follows,

[0025] a. Add fumed silica and dimethylcyclosiloxane to natural rubber, knead evenly in a kneader, treat at 140-170°C for 1-4 hours, then add platinum compound and mix well, Formulated with glue;

[0026] b. Mix the rubber material with carbon black, ammonia water, tung oil and compound phosphate on a double-roller rubber mixer to make a flame-retardant mixed silicone rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com