Quick detecting method for sudan red in food

A detection method, Sudan red technology, applied in the field of rapid detection of Sudan red in food, can solve the problems of expensive equipment, complicated operation, difficult to popularize, etc., and achieve the effect of convenient operation, simple equipment and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

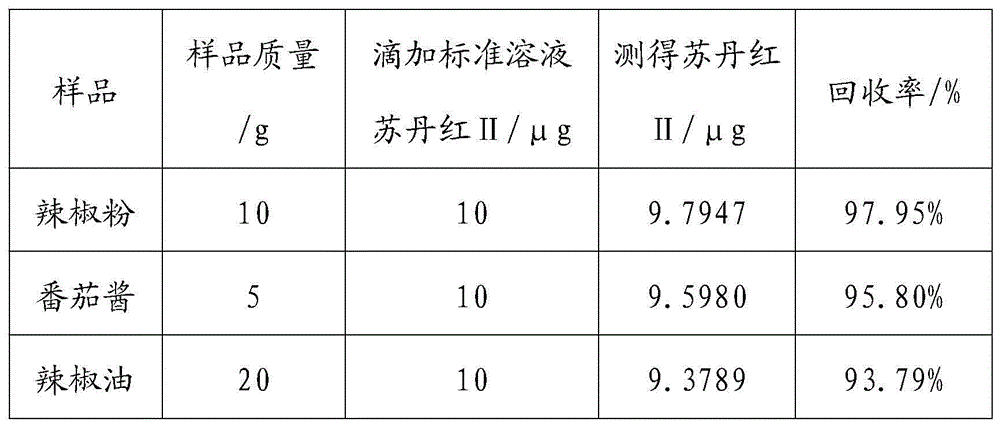

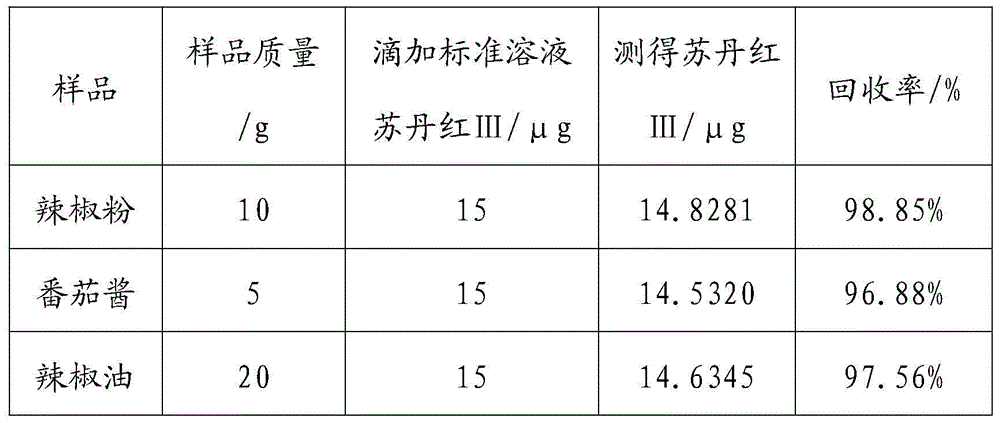

Embodiment 1

[0021] Weigh 10 g of red pepper powder into a centrifuge tube, add 30 mL of water for dilution, add 10 mL of a mixed solvent of n-hexane and acetone with a volume ratio of 5:3, shake for 1 min, extract by ultrasonic for 15 min, centrifuge at 3500 r / min for 1 min, filter, The residue was extracted twice with 10 mL and 5 mL of a mixed solvent of n-hexane and acetone with a volume ratio of 5:3, respectively, and the extracts were combined; the extract was placed in a distillation flask, and the distillation flask was placed in a 40°C water bath for rotary evaporation, Or add anhydrous sodium sulfate to the bottle for dehydration, filter and evaporate to dryness naturally; add 1 mL of acetone to dissolve the obtained in the previous step, pass through a polyamide thin-layer plate, and use chloroform:acetone:acetic acid=6:1:1 as a developing agent, The obtained crystals were dried and placed in a sampling bottle; acetonitrile was added to the upper sampling bottle to make the volume...

Embodiment 2

[0023] Weigh 5g of ketchup into a centrifuge tube, add 20mL of water for dilution, add 10mL of a mixed solvent of n-hexane and acetone with a volume ratio of 5:3, shake for 1min, extract by ultrasonic for 15min, centrifuge at 5000r / min for 1min, filter, and remove the residue. Extract twice with 10mL and 5mL of a mixed solvent of n-hexane and acetone with a volume ratio of 5:3 respectively, and combine the extracts; place the extracts in a distillation flask, and place the distillation flask in a 40°C water bath for rotary evaporation, or Add anhydrous sodium sulfate to the bottle for dehydration, filter and evaporate to dryness naturally; add 1 mL of acetone to dissolve the result obtained in the previous step, pass through a polyamide thin-layer plate, and use chloroform:acetone:acetic acid=6:1:1 as a developing agent, the obtained The crystals were dried and placed in a sampling bottle; acetonitrile was added to the upper sampling bottle to make the volume to 5 mL, shaken fo...

Embodiment 3

[0025] Weigh 20g of chili oil in a centrifuge tube, add 25mL of water for dilution, add 30mL of a mixed solvent of n-hexane and acetone with a volume ratio of 5:3, shake for 1min, extract by ultrasonic for 15min, centrifuge at 5000r / min for 1min, filter, and remove the residue. Extract twice with 10mL and 5mL of a mixed solvent of n-hexane and acetone with a volume ratio of 5:3 respectively, and combine the extracts; place the extracts in a distillation flask, and place the distillation flask in a 40°C water bath for rotary evaporation, or Add anhydrous sodium sulfate to the bottle for dehydration, filter and evaporate to dryness naturally; add 1 mL of acetone to dissolve the result obtained in the previous step, pass through a polyamide thin-layer plate, and use chloroform:acetone:acetic acid=6:1:1 as a developing agent, the obtained The crystals were dried and placed in a sampling bottle; acetonitrile was added to the upper sampling bottle to make the volume to 5 mL, shaken f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com