High-strength, low-temperature and wear-resistant power cable

A power cable, high-strength technology, applied in the direction of power cables, insulated cables, cables, etc., can solve the problems of easy cracking, weakened bending performance, and safety of material waste, and achieve high thermal stability, excellent mechanical properties, and high rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

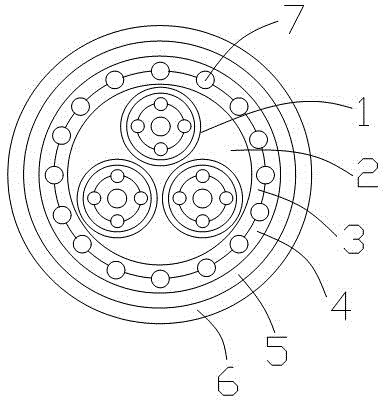

[0010] Specific implementation method: during production, the structure of each group of aluminum alloy conductor cable core 1 is that one aluminum alloy conductor is extruded at the center of the cable core, and the other four aluminum alloy conductors are evenly distributed between the silicone rubber insulation layer and the nickel tape armor layer Between the positions, the outermost layer is a non-magnetic metal armor layer.

[0011] Further, sixteen copper conductors 7 are extruded between the aluminum-clad copper armor layer 3 and the neoprene sheath layer 4 .

[0012] Further, the central aluminum alloy conductor is made of aluminum alloy wire twisted, and the cross section of the central aluminum alloy conductor is less than 12 mm 2 , greater than 10 mm 2 ; The cross-section of the aluminum alloy conductor evenly distributed between the silicone rubber insulation layer and the nickel tape armor layer is less than 9 mm 2 , greater than 5 mm 2 ; The copper conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com