Device for generation of high-power vacuum ultraviolet laser by direct frequency multiplication and method thereof

A vacuum ultraviolet and ultraviolet laser technology, which is applied in lasers, laser components, optics, etc., can solve the problems of low frequency doubling conversion efficiency, unstable power, low output power, etc., achieve high frequency doubling conversion efficiency and increase output power , the effect of narrow line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

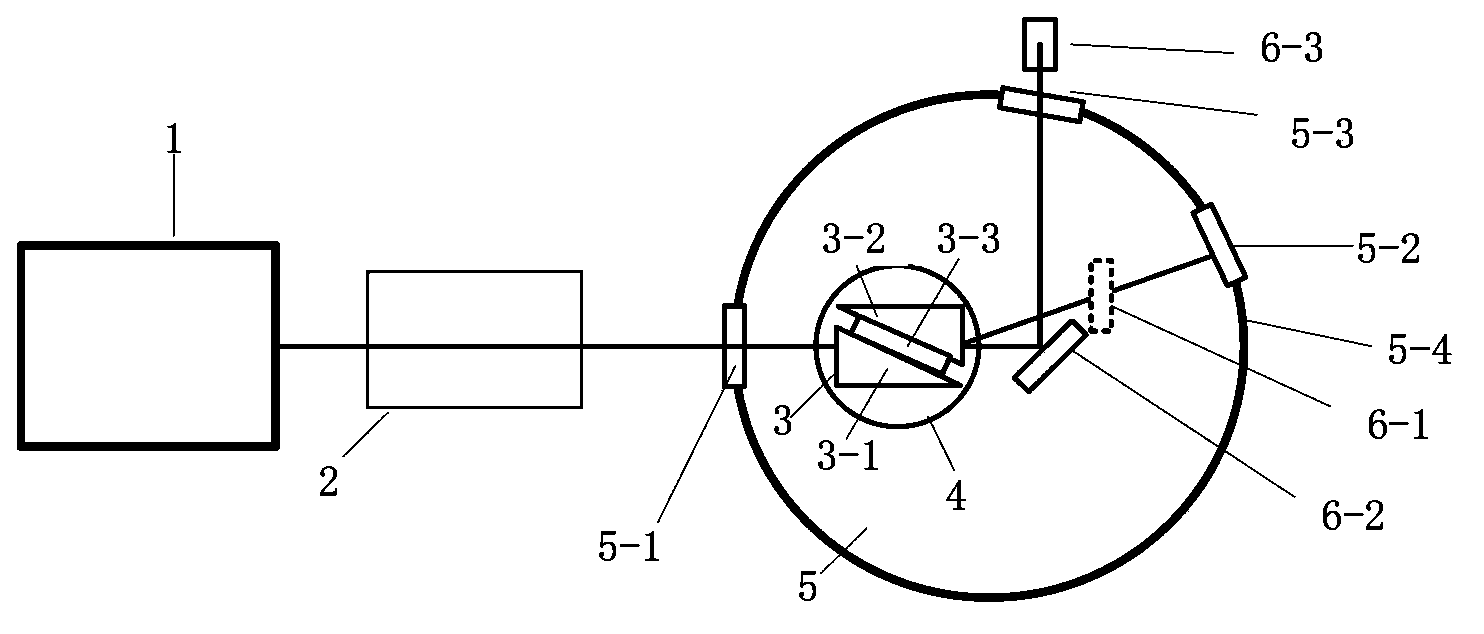

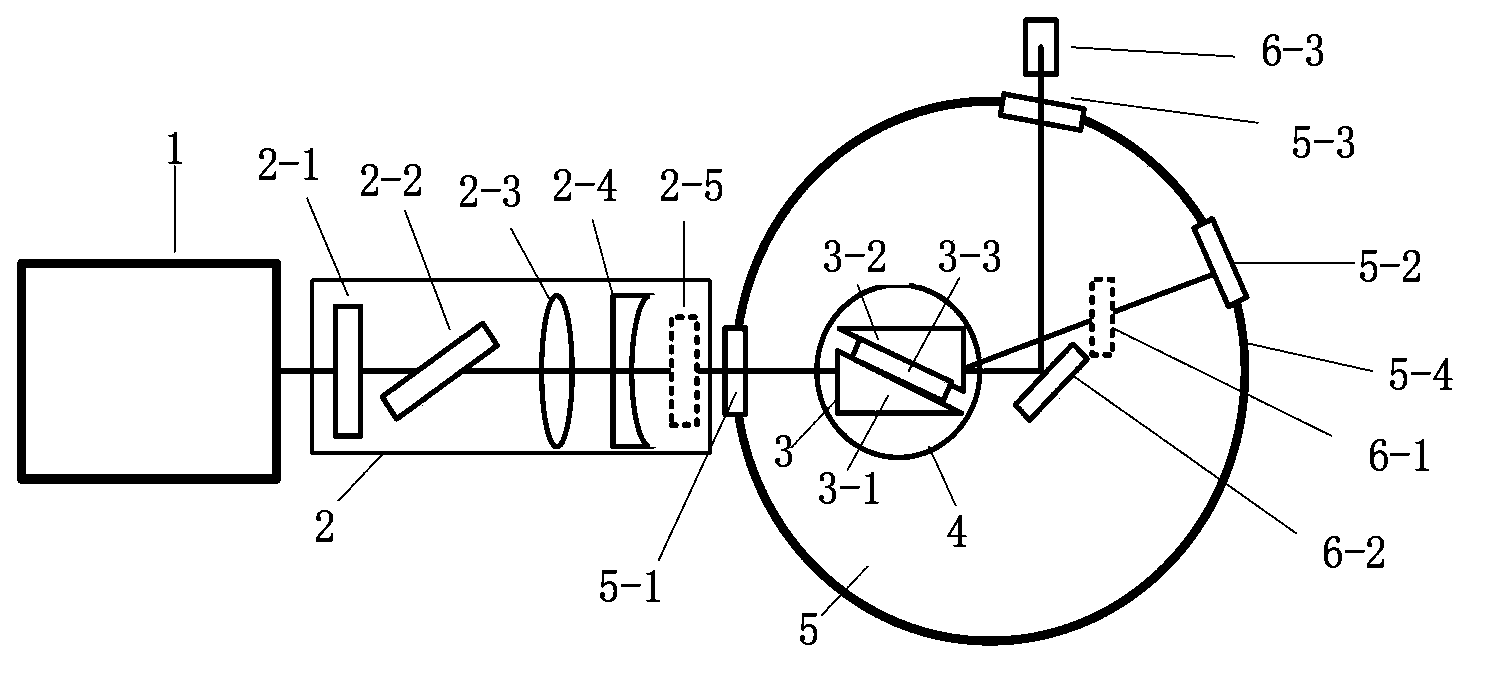

[0034] The invention provides a device for direct frequency doubling to generate high power: hundreds of milliwatts or even watts of vacuum ultraviolet laser, the device is as figure 1 The shown includes: a narrow-linewidth all-solid-state ultraviolet laser pump source (1), a direct frequency doubling device (3), a vacuum cavity (5) and a power measurement system (6); the device also includes a beam shaping system (2) And four-dimensional pre-adjustment flat turntable (4);

[0035] Wherein the beam shaping system is located between the laser pump source and the vacuum chamber; the four-dimensional pre-adjusted translation table is fixed in the vacuum chamber, including a three-dimensional electric translation table, a one-dimensional electric rotation table and corresponding adapter plates; The direct frequency doubling device is fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com