Asphalt flue gas processing system and processing technology

A technology of asphalt fume and treatment system, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., and can solve the problems of difficult cleaning of plates, secondary water pollution, and low purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

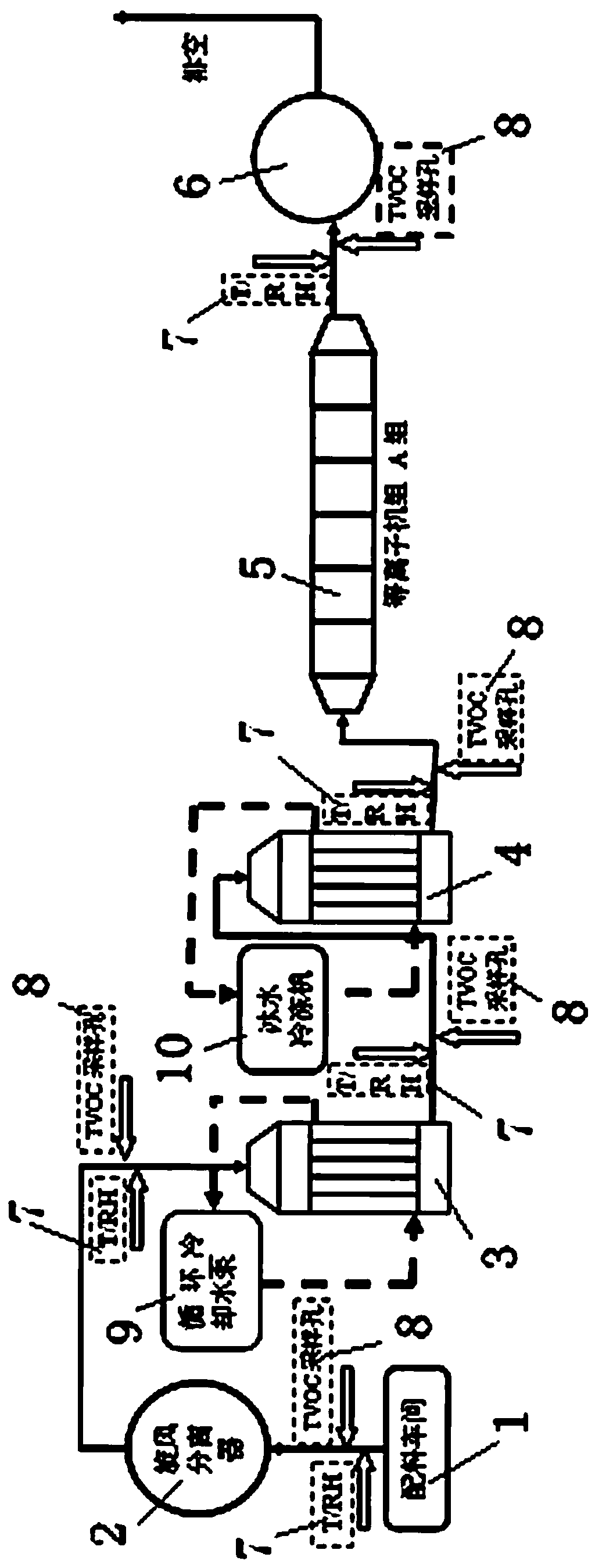

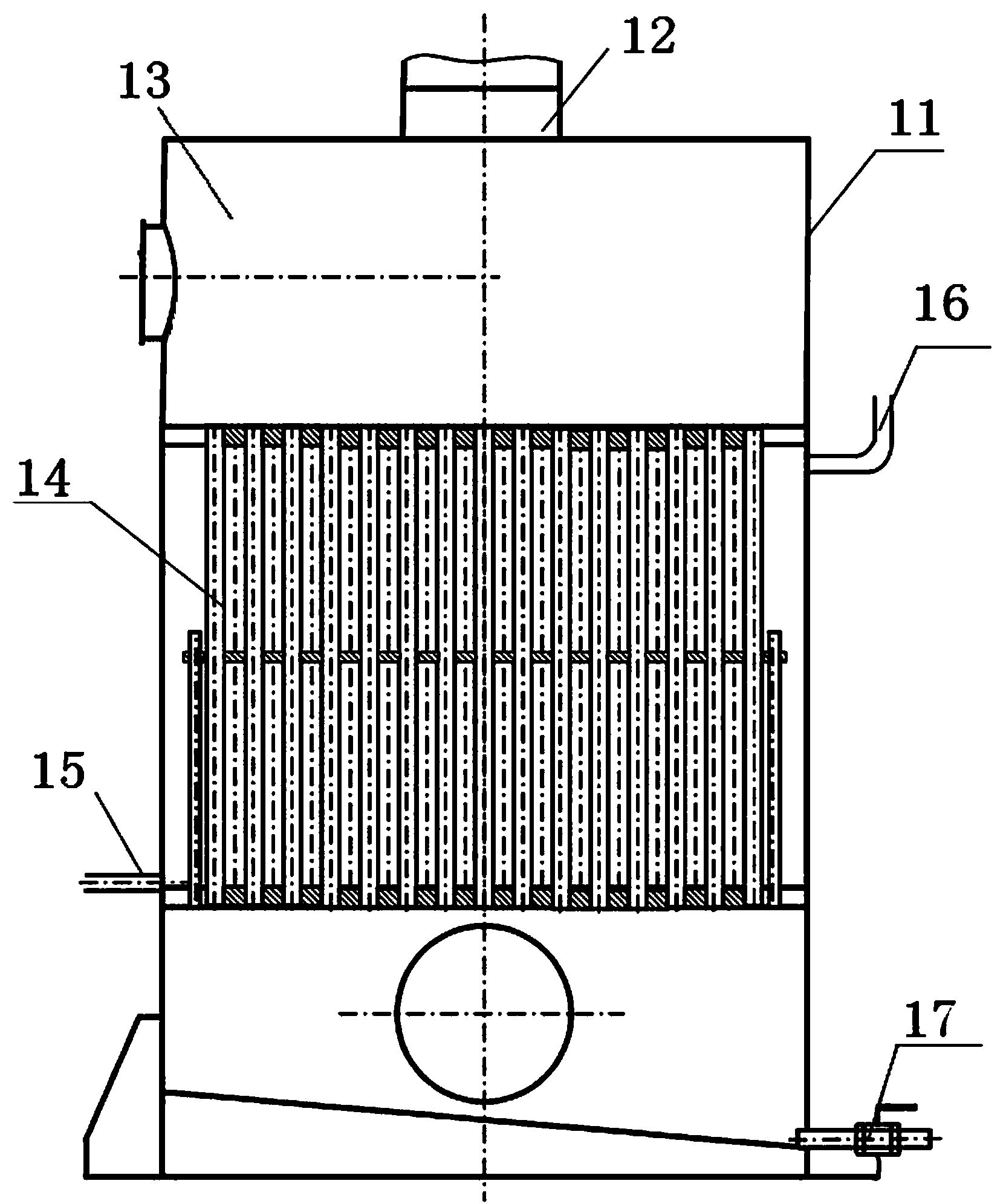

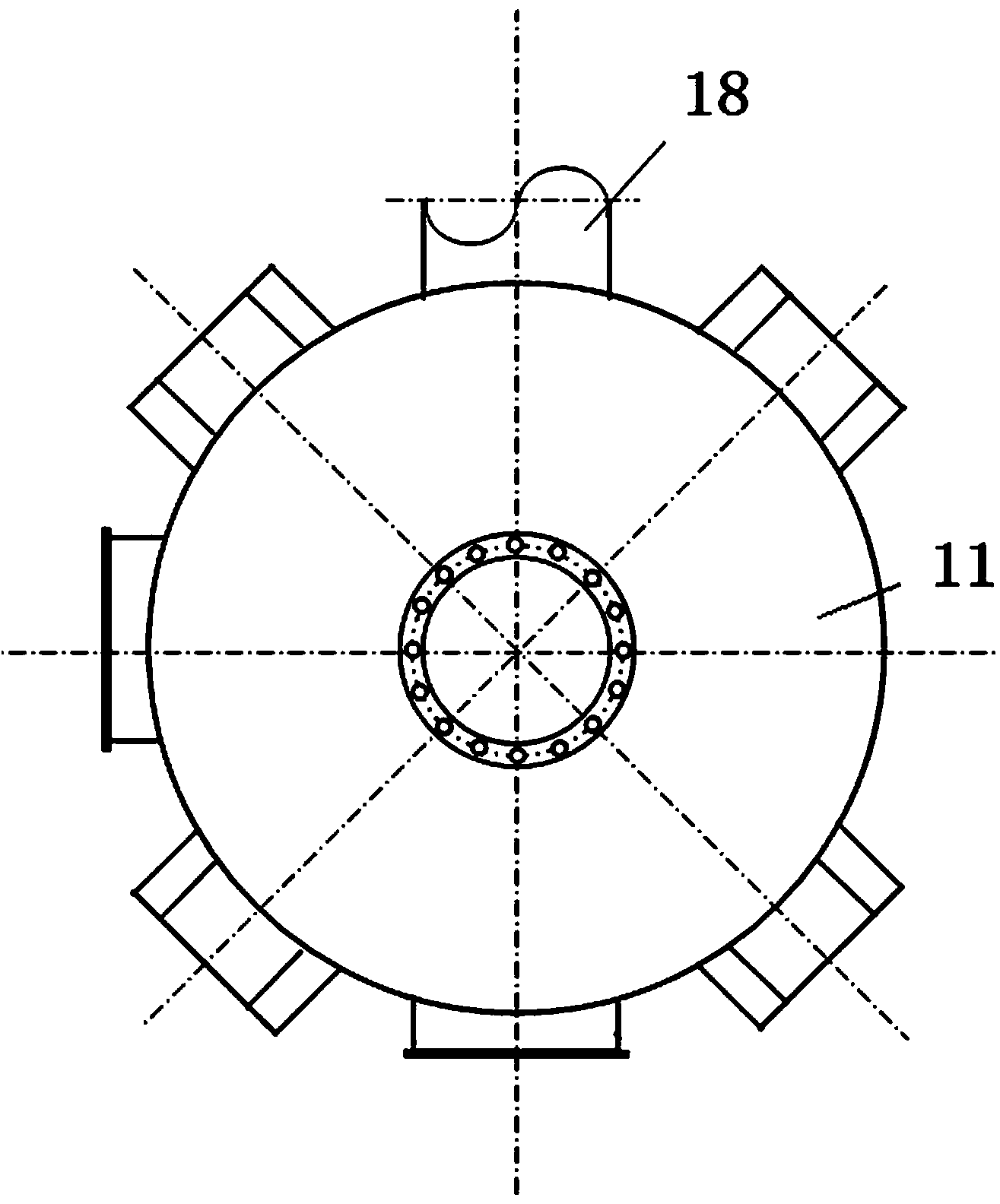

[0015] like figure 1 As shown, a bitumen flue gas treatment system is characterized in that the equipment includes a cyclone separator 2, which is used to separate and remove the solid matter in the flue gas discharged from the batching workshop 1, and the remaining gas-liquid matter in the flue gas is passed to the first stage Cooling tank 3; primary cooling tank 3, which cools the gas-liquid mixture treated by cyclone separator 2, wherein part of the oil and gas in the flue gas becomes liquid after being cooled, and deposits in the first stage together with the liquid substances therein At the bottom of the cooling tank 3, the remaining flue gas continues to lead to the secondary cooling tank 4; the secondary cooling tank 4 cools the flue gas treated by the primary cooling tank 3 again, and the remaining oil and gas in the remaining flue gas After being cooled, it deposits on the bottom of the secondary cooling tank 4, and the remaining flue gas leads to the plasma unit 5; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com