Micro-bubble generator

A technology of microbubble generator and vibration exciter, applied in solid separation, flotation water/sewage treatment, animal husbandry, etc. The effect of the probability of small mergers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

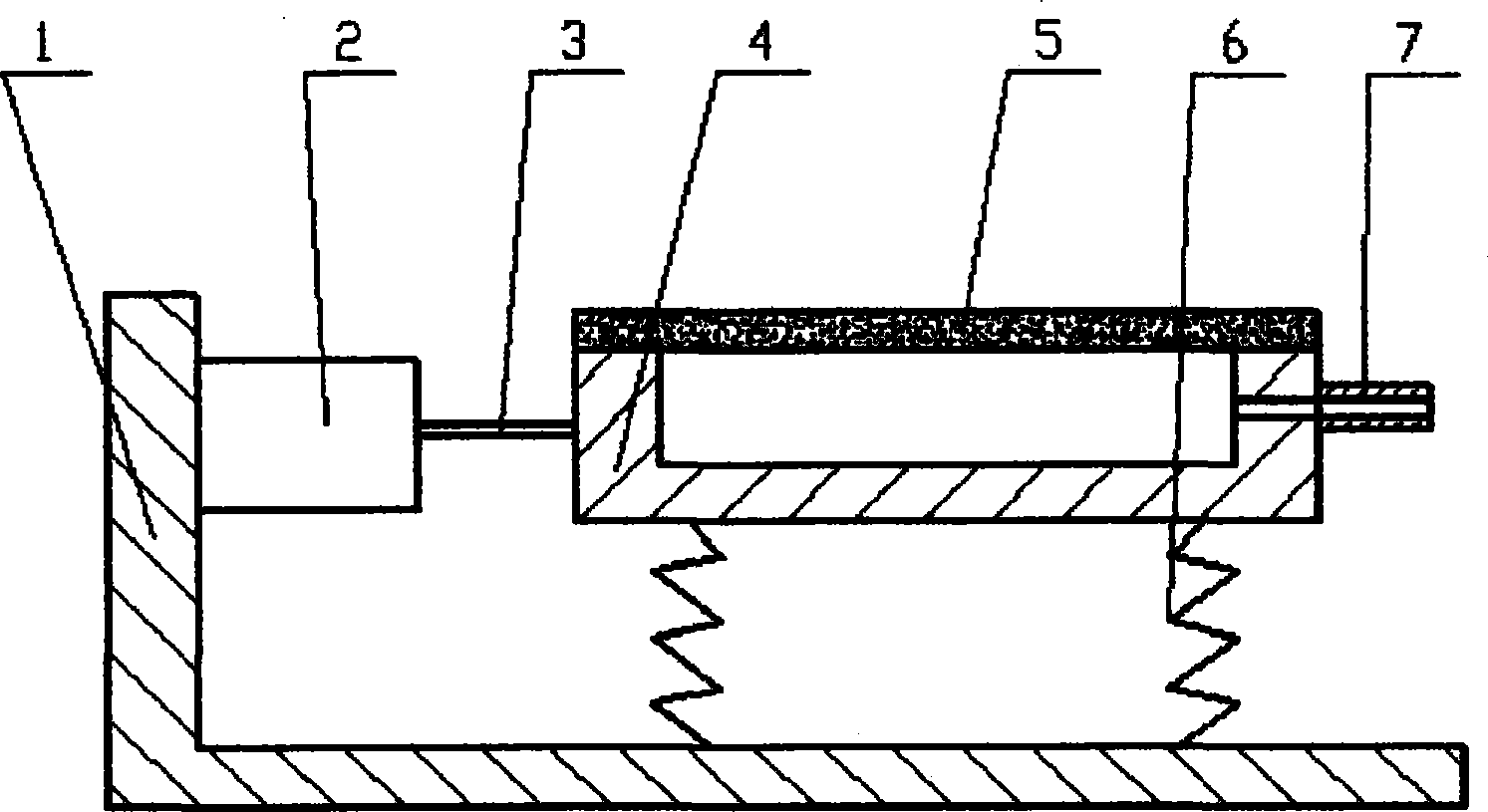

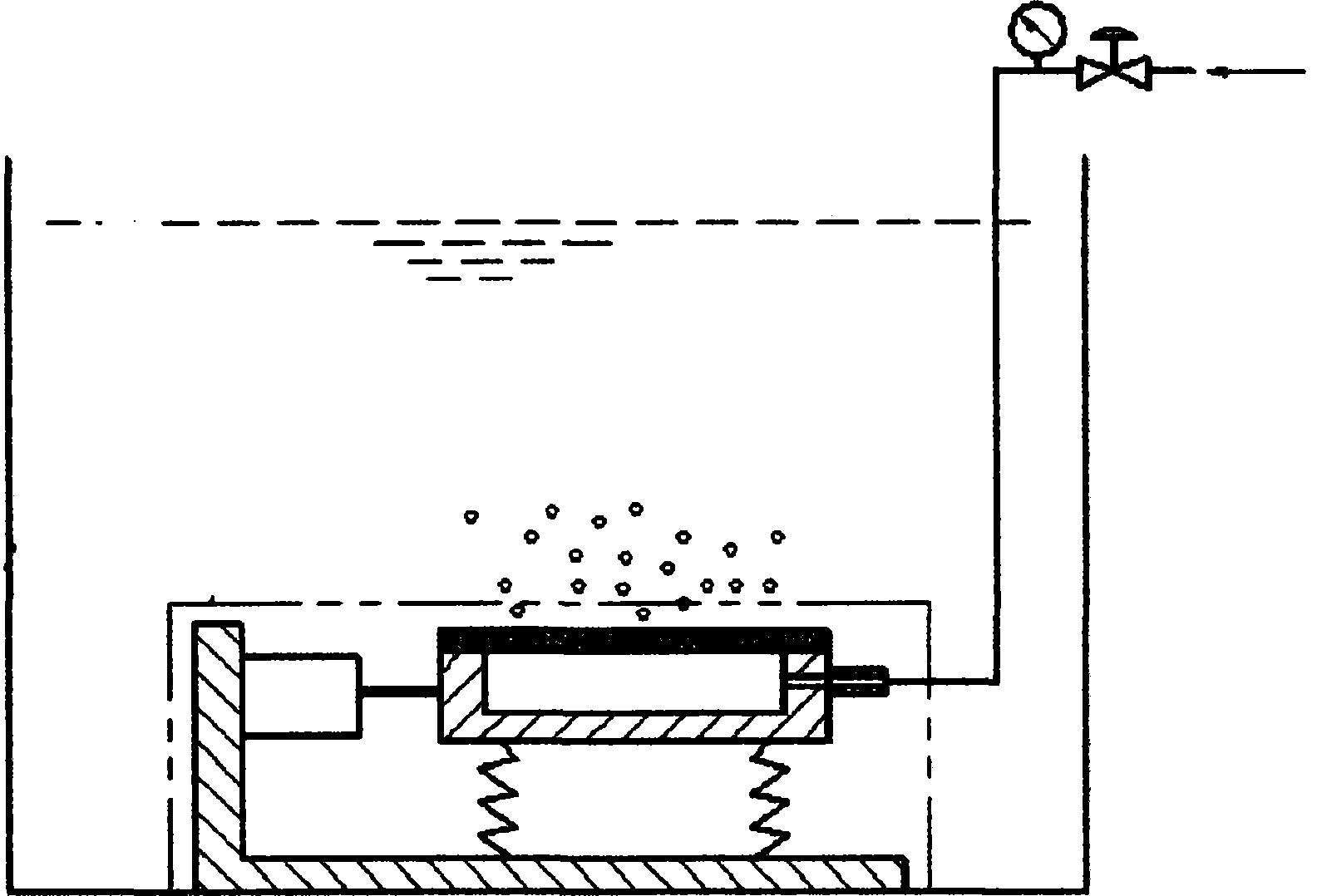

[0023] Such as figure 1 As shown, a microbubble generator includes a base 1 , an exciter 2 , a connector 3 , a chamber tank 4 , a microporous material 5 , a pressure gas inlet pipe 7 , and a flexible support 6 . The vibrator 2 is fixed on the base 1, the microporous material 5 is fixed on the chamber groove 4 to form a chamber, the vibrator 2 and the chamber groove 4 are connected by a connecting piece 3, and the chamber groove 4 is connected by a flexible support 6 Fixed on the base 1, the pressure gas inlet pipe 7 is fixed on the chamber groove 4 and communicates with the chamber.

[0024] In order to facilitate the control of gas parameters in the chamber, an air flow controller and a pressure gauge are provided on the pressure gas inlet pipe 7 .

[0025] The micropore diameter of the microporous material is 0.1 μm to 100 μm. Of course, the diameter of the microholes can also be adjusted according to actual needs.

[0026] In this embodiment, the base 1 is composed of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com