Method of synchronously generating electricity and methane by using excess sludge by microbial fuel cell

A fuel cell and excess sludge technology, applied in biochemical fuel cells, biological sludge treatment, waste fuel, etc., can solve the problems of low efficiency, achieve strong social benefits, reduce volume, and improve utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

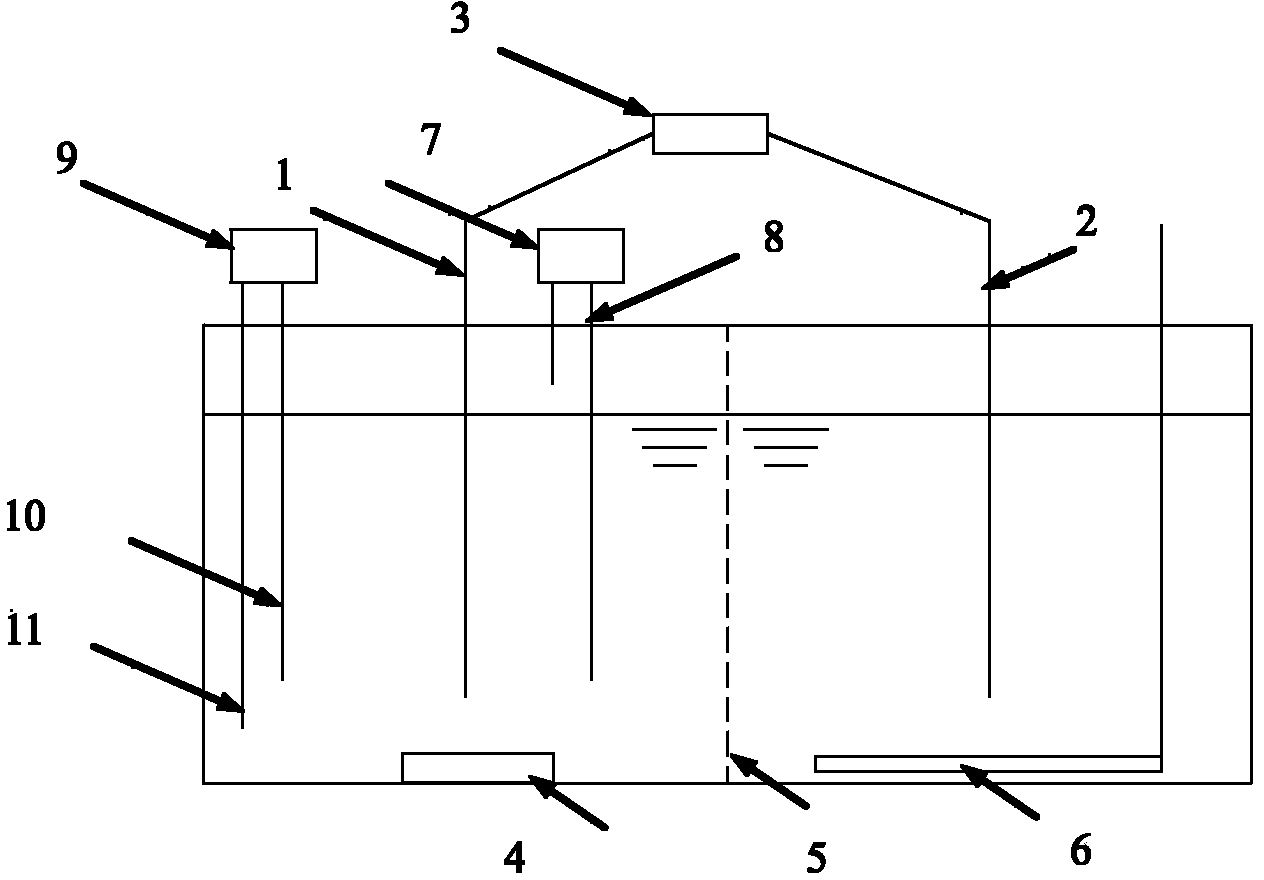

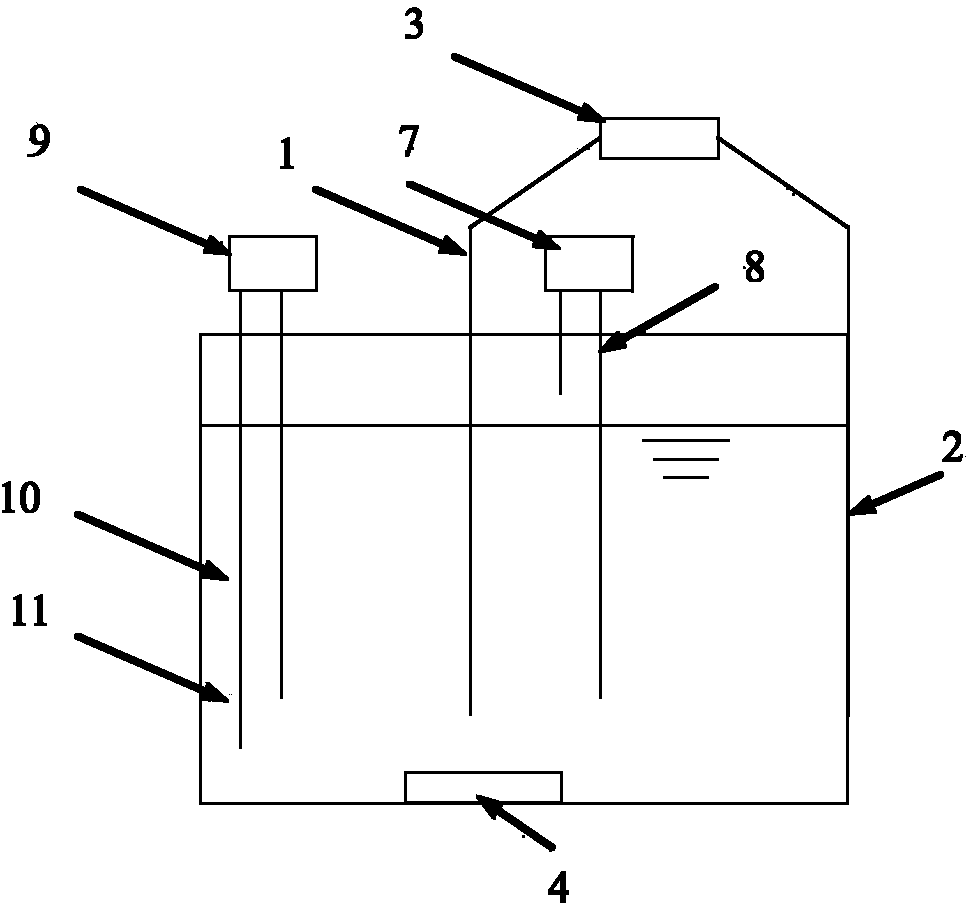

Image

Examples

Embodiment 1

[0027] A two-chamber microbial fuel cell is used. The volume of the two chambers is 500ml. The two chambers are separated by a proton exchange membrane. Both the positive and negative electrodes are made of carbon felt, and the cathode is plated with 0.25-0.5g / cm 2platinum. After sedimentation and concentration, the remaining sludge taken from the sewage treatment plant was adjusted to a concentration of 15g / L, and then it was mixed with the anaerobic sludge (concentration 15g / L) taken from the sludge anaerobic digestion tank by 10: 1 Mix, adjust the pH value of the mixed sludge to 7.0±0.1, and add 1mmol / L Fe 2+ (add FeCl 2 ), 100nmol / LNi 2+ (plus NiCl 2 ), 50nmol / L Co 2+ (plus CoCl 2 ), and add 10 μmol / L metal ion chelating agent nitrilotriacetic acid. After the mixed sludge is prepared, it is added to the anode chamber of the microbial fuel cell, and the concentrated sludge with a concentration of 10 g / L is added to the cathode chamber. The anode chamber was filled wi...

Embodiment 2

[0030] A single-chamber microbial fuel cell is used, the volume of the anode chamber is 500ml, and the anode uses carbon brushes. After the excess sludge from the sewage treatment plant was adjusted to 25g / L, it was heat treated at 121°C for 30min. Mix the pretreated residual sludge concentration with anaerobic sludge (concentration 10g / L) at a ratio of 2:1, adjust the pH value of the mixed sludge to 7.2±0.1, and add 1mmol / L Fe 2+ , 100nmol / L Ni 2+ 、50nmol / L Co 2+ , and add 10 μmol / L metal ion chelating agent nitrilotriacetic acid. The mixed sludge is then added to the anode chamber of the single-chamber microbial fuel cell. The anode chamber was filled with nitrogen and evacuated for 5 minutes and then sealed, and the two electrodes were connected with 1000Ω resistors. Afterwards, the microbial fuel cell was placed in a constant temperature environment of 37° C., and the anode chamber was stirred and mixed with a magnetic stirrer. Use a pH meter to control the pH value o...

Embodiment 3

[0033] The same dual-chamber microbial fuel cell as in Example 1 was used. After sedimentation and concentration, the remaining sludge from the sewage treatment plant is adjusted to 50g / L, and then it is mixed with the anaerobic sludge from the sludge tank at a ratio of 6:1 to adjust the mixed sludge. pH value to 6.8±0.1, and add 1mmol / L Fe 2+ (add FeCl 2 ), 100nmol / L Ni 2+ (plus NiCl 2 ), 50nmol / L Co 2+ (plus CoCl 2 ), and add 10 μmol / L metal ion chelating agent nitrilotriacetic acid. After the mixed sludge is prepared, it is added to the anode chamber of the microbial fuel cell, and the aerobic sludge with a concentration of 10 g / L is added to the cathode chamber. The anode chamber was filled with nitrogen and evacuated for 5 minutes and then sealed, and the two electrodes were connected with 500Ω resistors. Afterwards, the microbial fuel cell was placed in a constant temperature environment of 30° C., the anode chamber was stirred and mixed with a magnetic stirrer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com