Device for continuously destructing radiative waste organic solvent

An organic solvent and radioactive waste technology, which is applied in the field of devices for continuously destroying radioactive waste organic solvents, can solve the problems of low current efficiency, small processing capacity, and inability to meet the needs of large-scale industrial processing, and achieves high electrolysis efficiency and short electrolysis time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

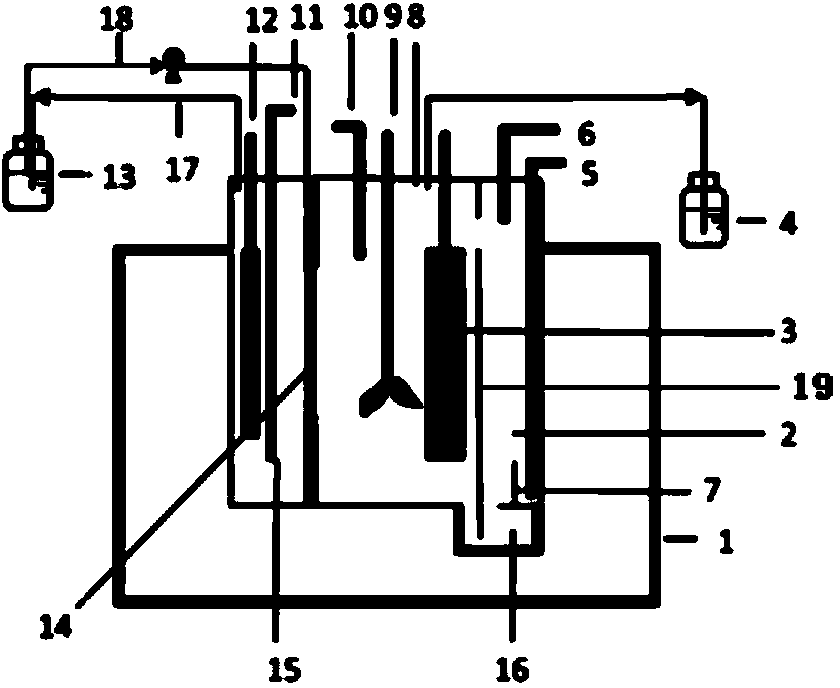

[0038] A device for continuously destroying radioactive waste organic solvents, the device includes a constant temperature tank 1 with a temperature setting of 55°C and an electrochemical oxidation destruction container located inside the constant temperature tank 1, the container is mainly composed of an anode chamber with a sealed cover on the top 8. The cathode chamber 15 and the clarification chamber 2 are composed, wherein the volume ratio of the cathode chamber 15 and the clarification chamber 2 is 1:1, and the volume ratio of the anode chamber 8 and the cathode chamber 15 is 4:1.

[0039] The inside of the anode chamber 8 is equipped with a stirrer 9, the stirrer 9, the oxidizing medium adding pipe 10, the tail gas outlet pipe of the anode chamber and the anode electrode 3 all enter the anode chamber 8 through the hole on the sealing cover, wherein the anode electrode 3 is a platinum electrode; The interior of the anode chamber 8 is equipped with Ag + HNO 3 The solutio...

Embodiment 2

[0047] Different from Example 1, the volume ratio of the anode chamber and the cathode chamber is 10:1, containing Ag + HNO 3 The solution acts as an oxidation medium, where Ag + The concentration is 0.5mol / L, HNO 3 The concentration of the solution is 7mol / L, the concentration of the nitric acid solution in the cathode chamber is 5mol / L, and the temperature of the constant temperature bath is 65°C. The current density is 0.5A / cm 2 , the voltage is 10V.

Embodiment 3

[0049] Different from Example 1, the volume ratio of the anode chamber and the cathode chamber is 8:1, containing Ag + HNO 3 The solution acts as an oxidation medium, where Ag + The concentration is 0.8mol / L, HNO 3 The concentration of the nitric acid solution in the cathode chamber is 8mol / L, the concentration of the nitric acid solution in the cathode chamber is 7mol / L, and the temperature of the constant temperature bath is 60°C. The current density is 0.6A / cm 2 , the voltage is 15V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com