Method for recycling iron tailing sand

A technology of iron tailing sand and recovery method, applied in the field of tailing sand recovery, can solve problems such as resource depletion, and achieve the effects of solving environmental problems, efficient recycling, solving environmental problems and resource depletion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

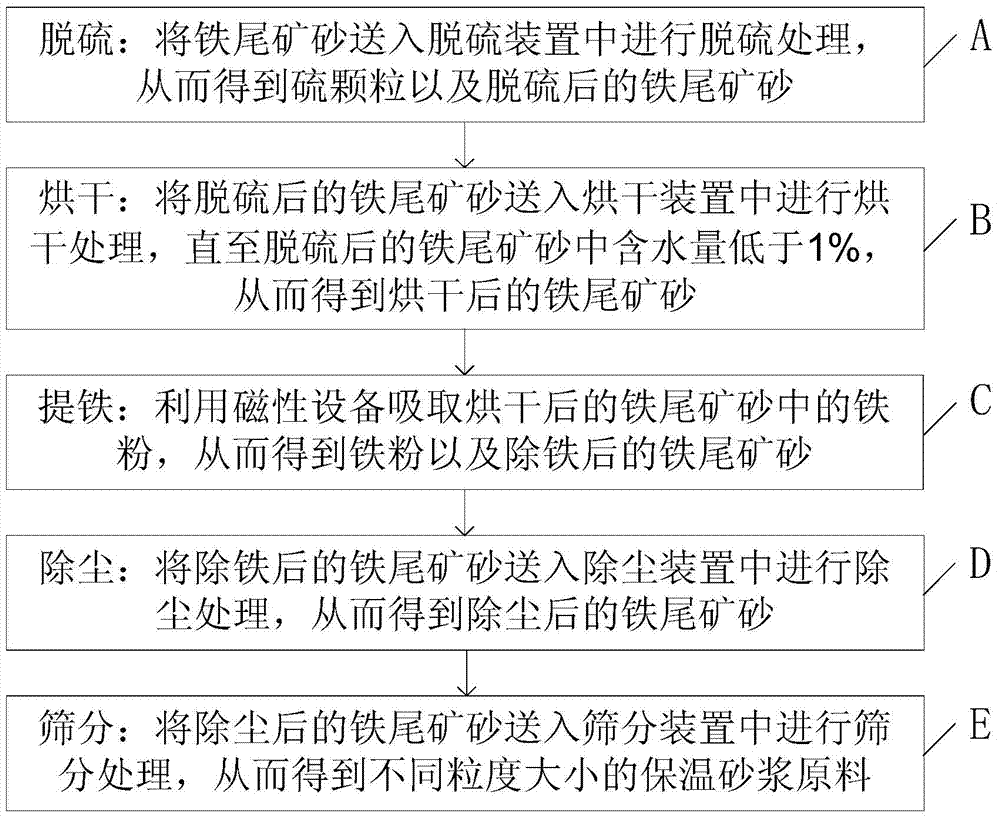

[0020] Such as figure 1 Shown, a kind of tailings sand recovery method, it specifically can comprise the following steps:

[0021] A. Desulfurization: The iron tailings are sent to the desulfurization device for desulfurization treatment, so as to obtain sulfur particles and desulfurized iron tailings.

[0022] Wherein, the desulfurization device may adopt a desulfurization centrifuge in the prior art; since the desulfurization centrifuge belongs to the category of the prior art, it will not be described in detail in this application document. After the desulfurization treatment in this step, the sulfur particles in the iron tailings are effectively recovered, thereby avoiding the waste of sulfur resources.

[0023] B. Drying: Send the desulfurized iron tailings into a drying device for drying until the water content in the desulfurized iron tailings is lower than 1%, so as to obtain dried iron tailings.

[0024] Among them, the drying device can adopt the drying device in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com