Viscose composite sound-absorbing saw blade matrix

A sound-absorbing saw blade and substrate technology, which is applied in the direction of metal sawing equipment, sawing machine tools, metal processing equipment, etc., to achieve the effects of reducing thermal deformation, reducing noise generation and noise transmission, and reducing vibration generation and vibration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

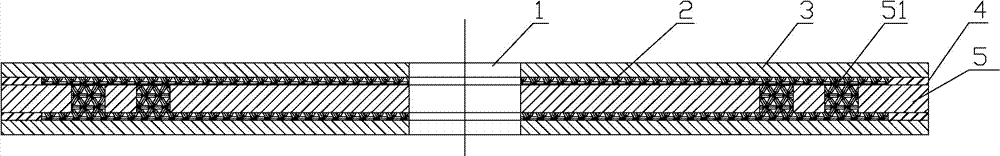

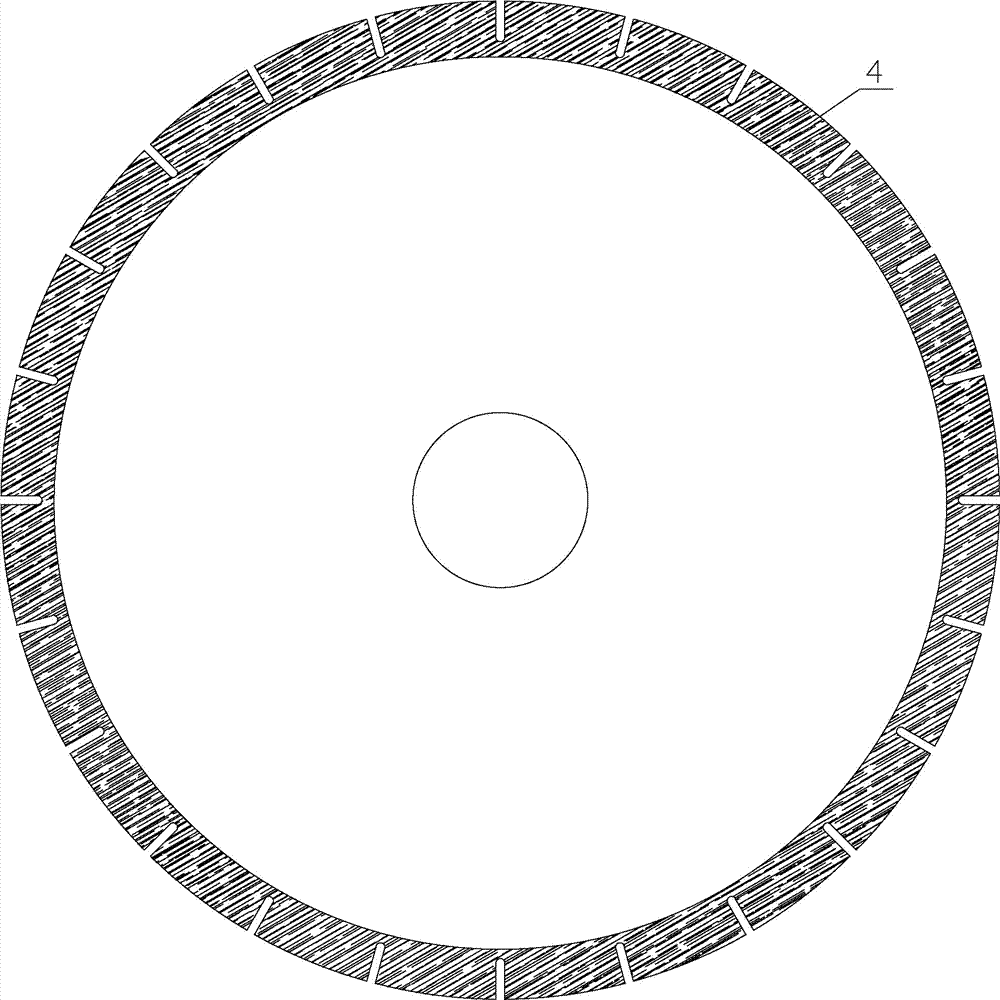

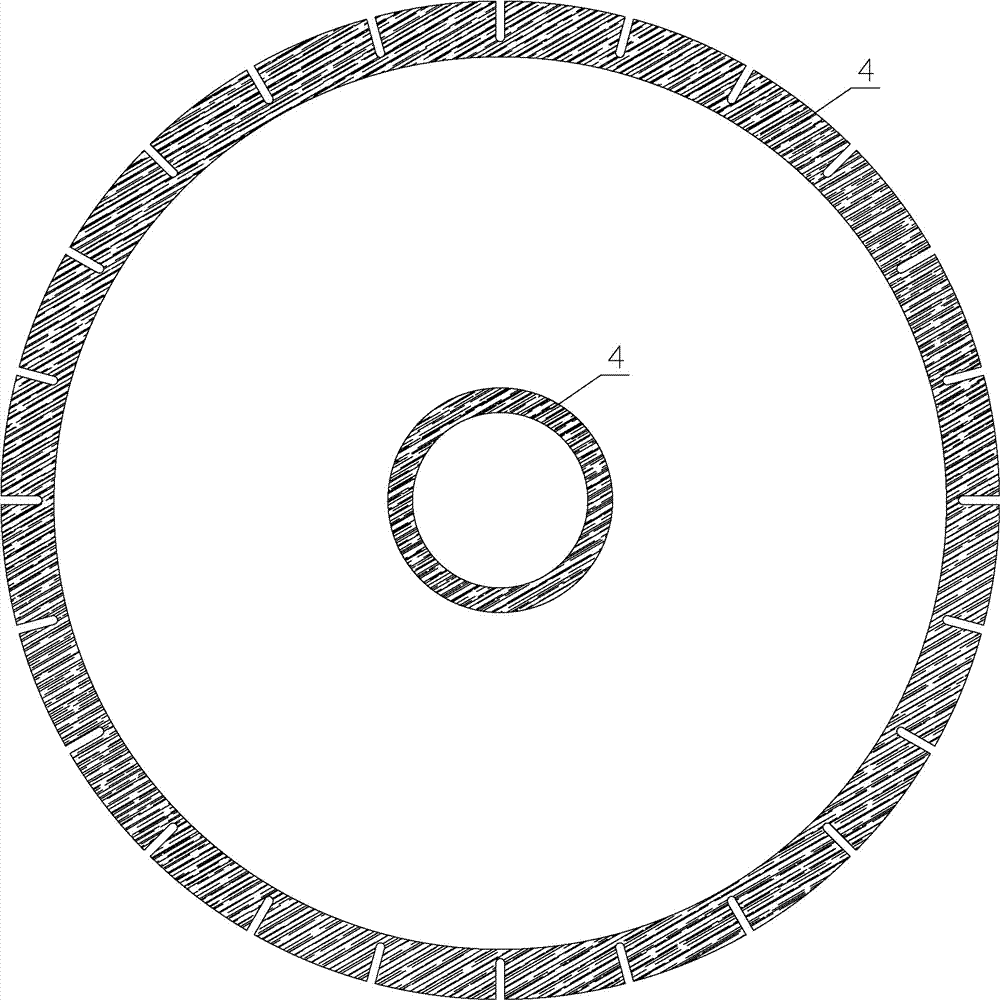

[0024] Such as figure 1 Among them, a viscose composite sound-absorbing saw blade base includes a saw blade base, a central hole 1 is provided in the center of the saw blade base, and the saw blade base is formed by bonding three layers of metal plates through an adhesive layer 2 . On the one hand, the provided adhesive layer 2 can ensure the overall connection strength of the three-layer metal plates and the rigidity of the saw blade substrate, and on the other hand, as a damping medium, the vibration and noise generated during sawing can be effectively reduced.

Embodiment 2

[0026] In a preferred solution, the three layers of metal plates have the same thickness, which is not shown in the figure. This structure is convenient for processing, and as a mass production on the production line, the processing cost of this structure is the lowest.

Embodiment 3

[0028] The preferred solution is as figure 1 Among them, the metal plate has three layers, and the thickness of the middle metal plate 5 is greater than the thickness of the outer matrix 3 . After testing, the noise reduction effect of this structure is better than that of Example 2. The specific reason is unknown, but it is speculated that the vibration frequencies generated will cancel each other out due to the different thicknesses of the metal plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com