Preparation method of graphene thin films

A graphene film and graphite technology, applied in the field of graphene film preparation, can solve the problems of few layers, harsh preparation conditions, high cost and difficult peeling, etc., and achieves the effects of simple operation, low cost and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A kind of preparation method of graphene thin film, comprises the following steps:

[0017] Step 1) First remove the conductive glass, cut several pieces of small glass with a size of 3cm×1cm with a glass knife, and lay them on filter paper for cleaning;

[0018] Step 2) Form graphite oxide colloid or suspension into graphite oxide in water by ultrasonic wave, choose N,N-dimethylformamide (DMF) solution, prepare DMF solution with a concentration of 1mg graphite oxide / mL, seal and store, stand-by;

[0019] Step 3) Drop the solution prepared in step (2) on the prepared glass conductive surface, shake it left and right, place it in a glass container, and dry it in a desiccator for half an hour before storing it for use;

[0020] Step 4) The conductive glass is connected through the working electrode, the electrolytic solution is KCl solution, and the graphene film is obtained by electrolysis at a constant potential.

[0021] Further, the cleaning method in the step (1) i...

Embodiment

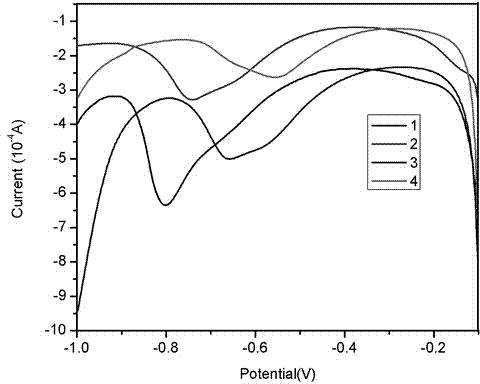

[0023] Example: CuInS 2 Photoelectric effect test of film / graphene

[0024] CuInS 2 As a light-absorbing material for solar cells, the main function of thin film is to convert light energy into electrical energy. It has attracted extensive attention due to its excellent comprehensive characteristics. This embodiment is mainly to test the effect of thin-layer graphene on CuInS 2 film effect. As can be seen from the figure, comparing curves 1 and 3, CuInS coated with graphene 2 The photocurrent in thin film case is smaller than CuInS 2 The photocurrent of the film alone, although the graphene film at this time is very thin, it still has a certain hindering effect on light, and graphene itself also has an absorption effect on light. The absorbance of visible light is 2.3%. [21] , so to reach CuInS 2 The light energy on the surface of the film has been weakened, and the photocurrent will naturally decrease. In the case of dark state, the photocurrent is obviously smaller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com