Leaching method of complex zinc calcined ores

A zinc roasting and leaching technology is applied in the field of metallurgy, which can solve the problems of large amount of iron slag, unsatisfactory quality of middle and supernatant, and difficulty in controlling the ratio of iron and arsenic in leaching solution, so as to achieve the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

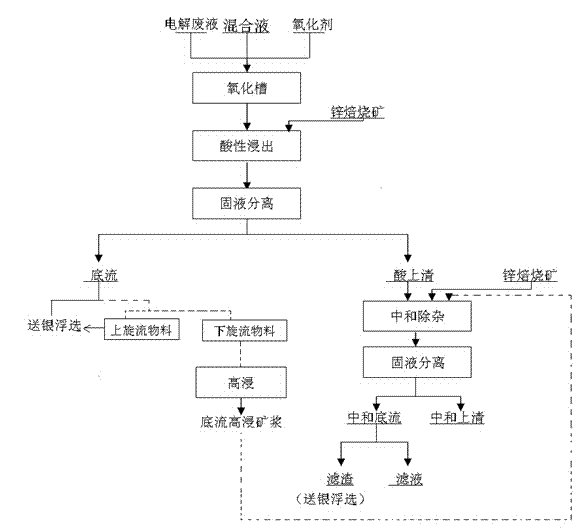

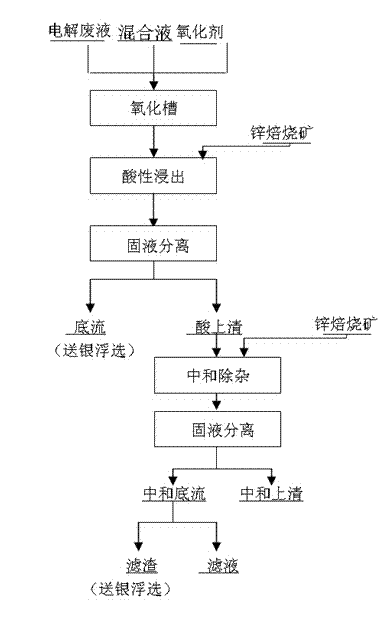

[0027] Embodiment 1: as figure 1 , 2 The leaching method of the high iron and high arsenic zinc roasted ore shown is as follows:

[0028] (1) Mix the electrolytic waste liquid and the hydrometallurgy mixed liquid according to the mass ratio of 2:1 and place it in 80M 3 In the oxidation tank, and add manganese powder in the oxidation tank, so that the acid in the mixed solution is 60g / L, Fe 2+ <0.01g / L;

[0029] (2) Put the oxidized solution in step (1) in the first leaching tank and add high iron and high arsenic zinc roasted ore. The amount of high iron and high arsenic zinc roasted ore added is calculated based on the concentration of acid in the solution as 20g / L. The pulp in the first leaching tank enters the second leaching tank, and high-iron, high-arsenic and zinc roasted ore is added into the second leaching tank. The amount of high-iron, high-arsenic and zinc roasted ore added is calculated on the basis that the pH value of the pulp at the outlet of the second leac...

Embodiment 2

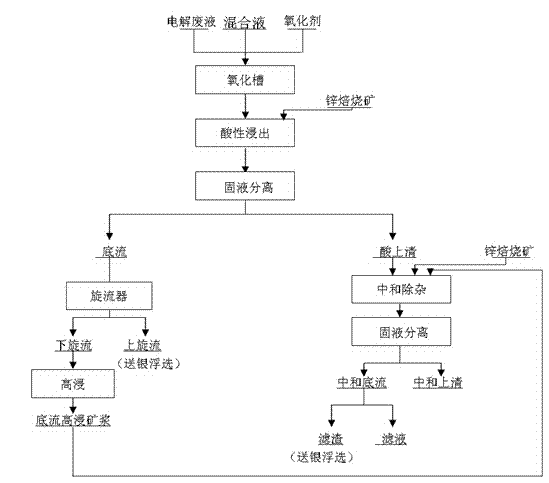

[0031] Embodiment 2: as image 3 The leaching method of the shown low-iron and high-arsenic zinc roasted ore is as follows:

[0032] (1) Mix the electrolytic waste solution and the mixed solution at a ratio of 3:1, pump them into the oxidation tank, and add electrolytic anode slime to the oxidation tank, so that the acid in the mixed solution after oxidation is 80 g / L, Fe 2+ <0.01g / L;

[0033] (2) Put the oxidized solution in step (1) in the first leaching tank and add low iron and high arsenic roasted ore. The acidity of the first tank can be guaranteed to ensure the leaching rate of zinc. The pulp in the first leaching tank enters the second leaching tank, and low-iron and high-arsenic roasted ore is added in the second leaching tank. Low-iron and high-arsenic roasted ore The amount of addition is calculated based on the pH value of the pulp at the outlet of the second leaching tank is 2.5, and the pulp in the second leaching tank enters the third leaching tank for acid l...

Embodiment 3

[0035] Embodiment 3: the leaching method of high iron and high arsenic zinc roasted ore, concrete operation is as follows:

[0036] (1) Mix the electrolytic waste liquid and the hydrometallurgy mixed liquid at a mass ratio of 3:1 and place it at 80M 3 In the oxidation tank, and add electrolytic anode slime in the oxidation tank, so that the acid in the mixed solution is 100g / L, Fe 2+ <0.01g / L;

[0037] (2) Put the solution oxidized in step (1) in the first leaching tank and add high iron and high arsenic zinc roasted ore. The pulp in the first leaching tank enters the second leaching tank, and high iron and high arsenic zinc roasted ore is added into the second leaching tank. The amount of high iron and high arsenic zinc roasted ore added is calculated based on the pH value of the pulp at the outlet of the second leaching tank being 2.2. The ore pulp in the second leaching tank enters the two leaching tanks for acid leaching treatment, and the flow rate of the ore pulp durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com