Method and system for depositing indium tin oxide at low temperature

A technology of indium tin oxide and deposition method, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of lower resistivity and low transmittance, and achieve improved production efficiency and good crystallinity , Improve the effect of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

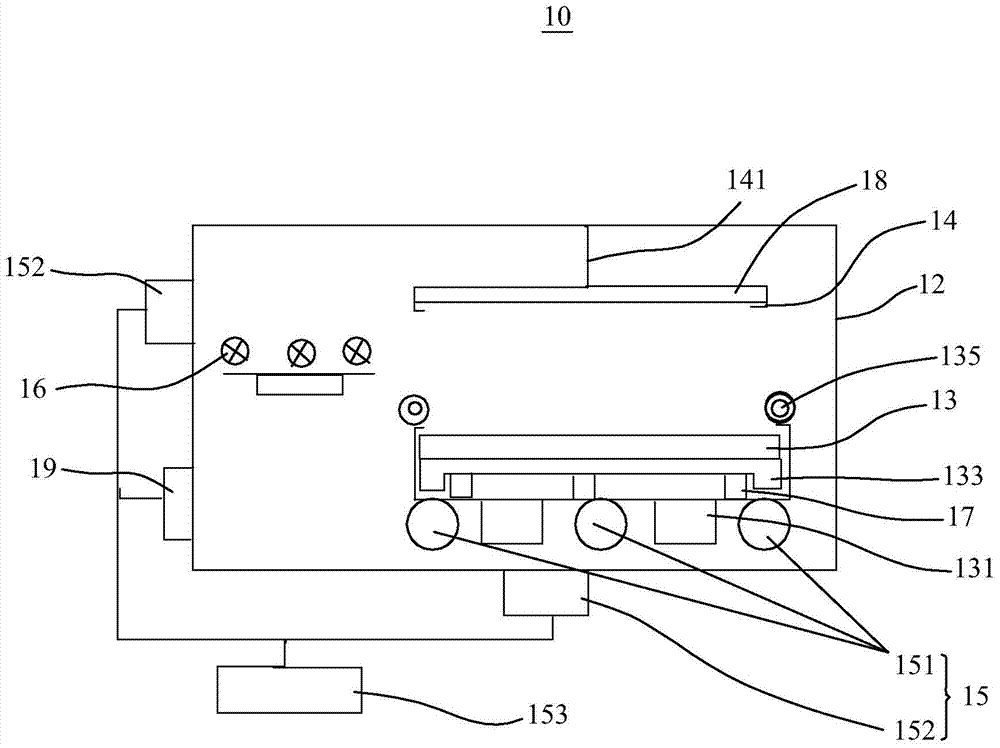

[0019] see figure 1 , shows an indium tin oxide low-temperature deposition system 10 provided by an embodiment of the present invention, which includes a vacuum coating chamber 12, an indium tin oxide target 13, and a substrate support device 14 opposite to the target 13, and also includes a cooling A cooling and degassing device 15 and a magnetic field device 17 for removing water vapor and impurity gases in the vacuum coating chamber 12, the cooling and degassing device 15 is installed around the indium tin oxide target 13, and the magnetic field sent by the magnetic field device 17 makes the indium tin oxide target The surface magnetic field strength is in the range of 600-900 Gauss.

[0020] figure 1 Among them, the base material 18 can be a sheet base material or a roll material, and the base material example is a sheet, and the base mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com