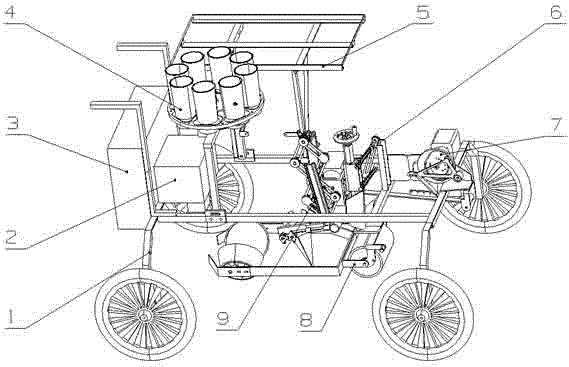

Electric self-propelled seedling transplanting machine

A self-propelled, transplanting machine technology, applied in transplanting machinery, planting methods, applications, etc., can solve the problems of low production efficiency, high labor intensity, slow transplanting speed, etc., and achieve convenient maintenance and low use cost. , Simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

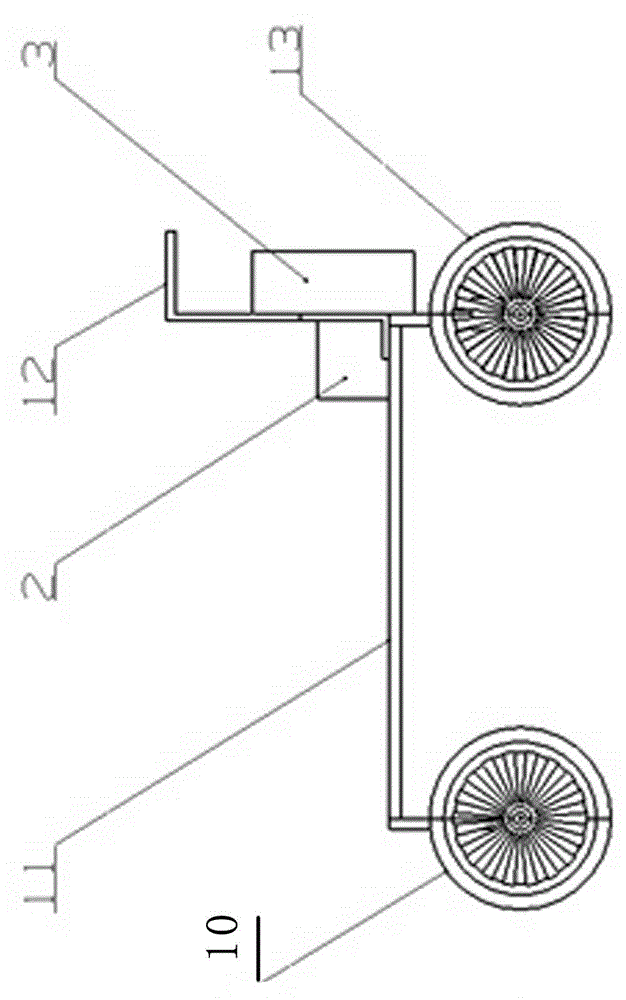

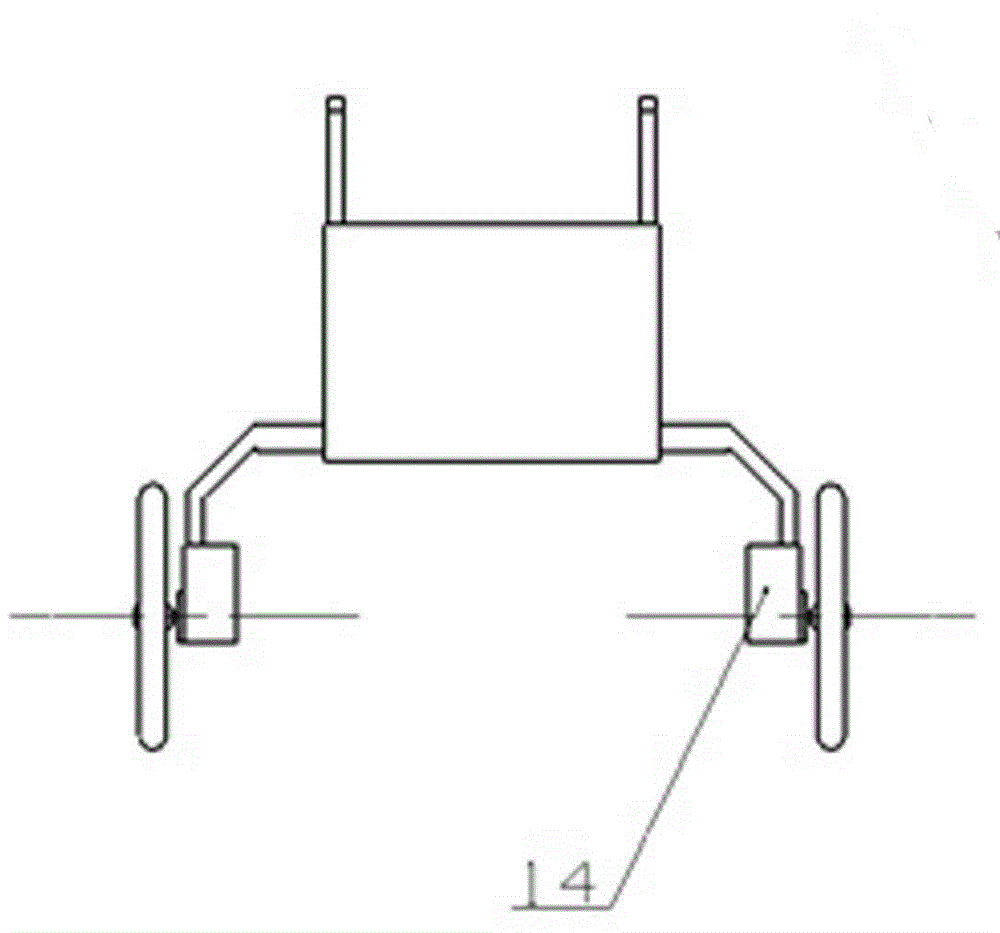

Embodiment 1

[0033] Example 1 : As for the transplanting machine, in the farmland where the rotary tillage has been ridged, according to the ridge specification of the farmland, use the adjustment rod 60, the adjustment knob 61, the connecting rod 62, the fine-tuning handle 63, and the adjustment screw rod 64 on the planting height adjustment mechanism 6 to adjust the return to the soil. The height of mechanism 8 and rice shoot transplanting mechanism 9 meets actual ridging requirements. Adjust the hole positions on the fork 72 and the connecting rod 71 according to the size of the pond required. Put the seedlings that need to be transplanted in the seedling tray, and complete the preparation work before planting. After power-on, the storage battery 2 uses a lithium battery as a power source to control the start of the left and right self-propelled drive motors 14. The guide wheel 10 protects the edge of the ridge, and the transplanter moves forward by itself. When the seedling cup 44 t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap