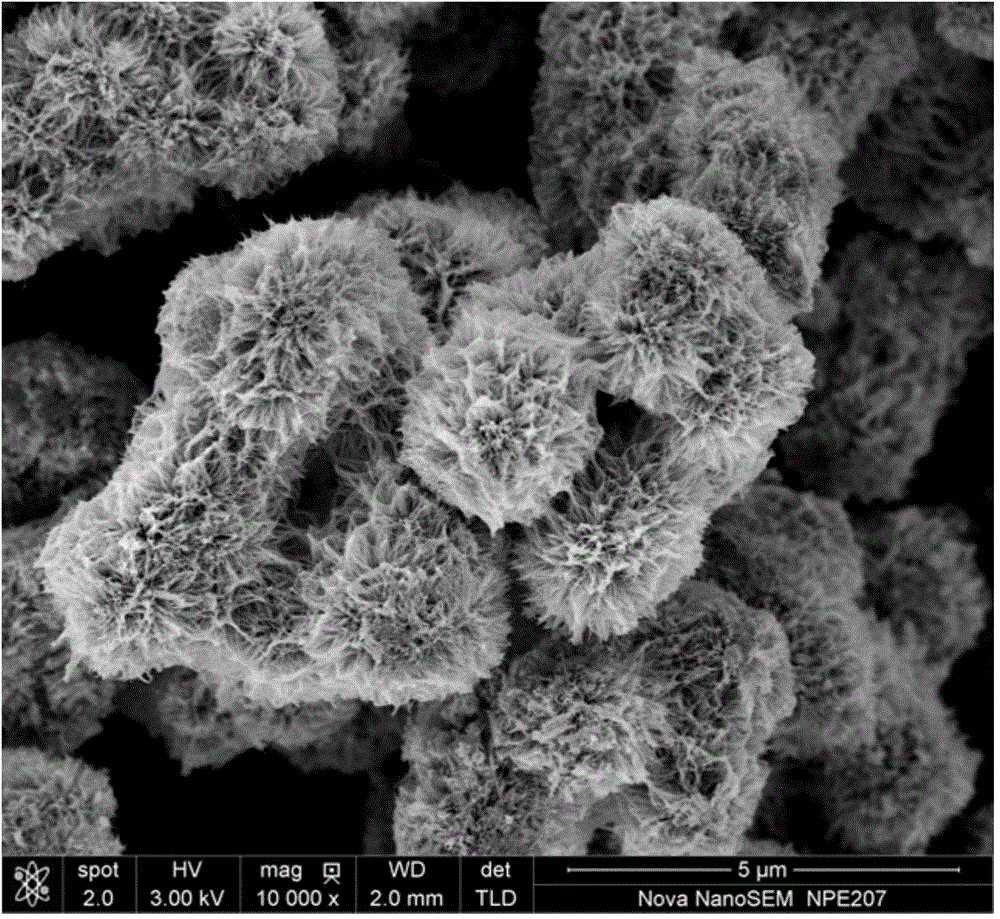

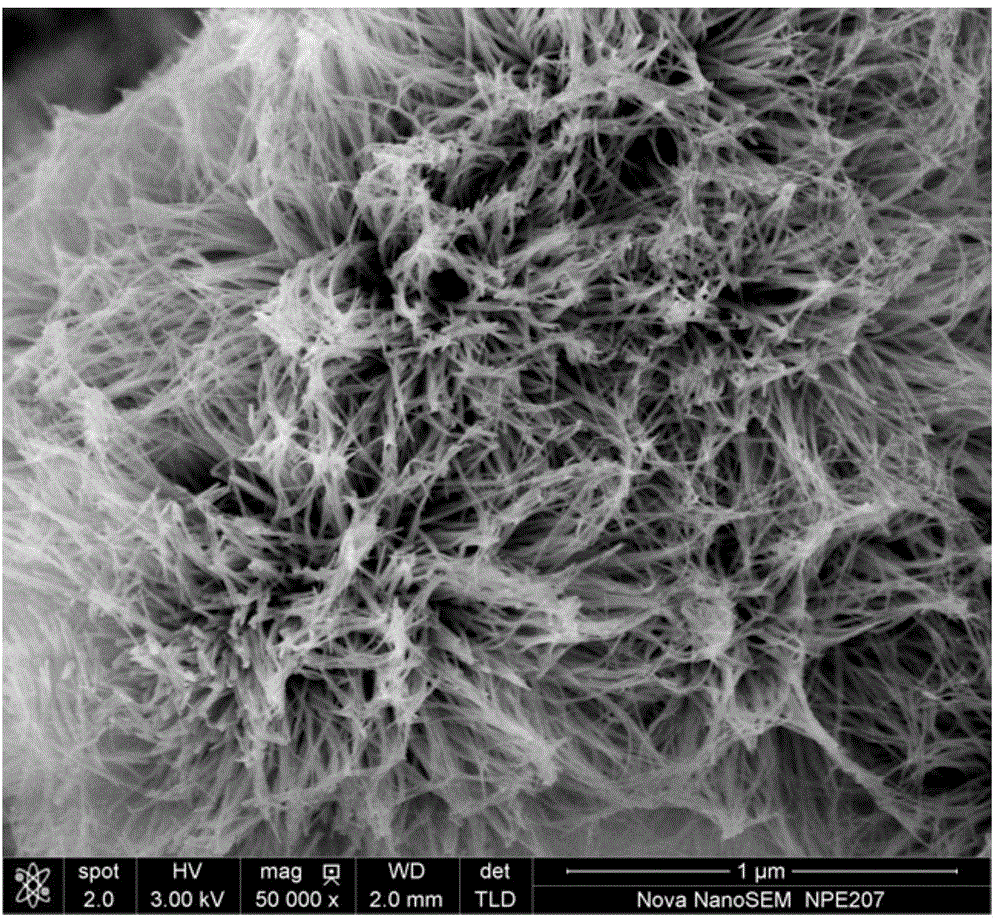

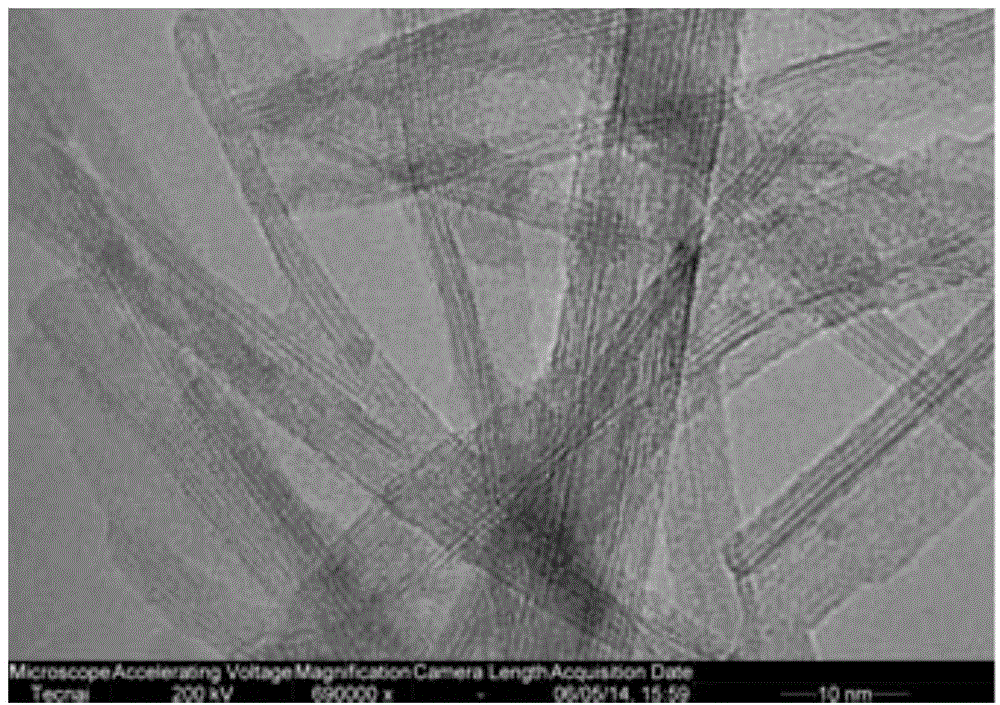

Preparation method of self-assembled three-dimensional Pt/TiO2 hierarchical-structure photocatalyst

A hierarchical structure, photocatalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as low catalytic performance and cumbersome preparation process, and achieve The effect of high quantum efficiency, simple preparation process and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment 1: This embodiment is a self-assembled three-dimensional Pt / TiO 2 The preparation method of the hierarchical structure photocatalyst is completed according to the following steps:

[0026] 1. First, mix tetrabutyl titanate / ethylene glycol mixed solution with chloroplatinic acid / ethylene glycol mixed solution to obtain mixed solution A; then add mixed solution A to NaOH with a concentration of 5mol / L~10mol / L In the aqueous solution, stir at a stirring speed of 200r / min to 400r / min for 1h to 3h to obtain a mixed solution B;

[0027] The tetrabutyl titanate / ethylene glycol mixed solution described in step 1 is formed by mixing tetrabutyl titanate and ethylene glycol, and the tetrabutyl titanate / ethylene glycol mixed solution in the tetrabutyl titanate The concentration of ester is 0.1mol / L~0.5mol / L;

[0028] The chloroplatinic acid / ethylene glycol mixed solution described in step 1 is formed by mixing chloroplatinic acid and ethylene glycol, and the c...

specific Embodiment approach 2

[0036] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the concentration of tetrabutyl titanate in the tetrabutyl titanate / ethylene glycol mixed solution described in step 1 is 0.3mol / L~0.5mol / L L. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the concentration of tetrabutyl titanate in the tetrabutyl titanate / ethylene glycol mixed solution described in step 1 is 0.5mol / L . Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap