Universal automatic machining device for turning and milling of screwdriver head

A technology of automatic processing and screwdriver bits, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of single processing object and process, high cost of screwdriver head processing, unsuitable screwdriver bits, etc., to simplify the assembly structure and improve The effect of reciprocating feed speed and work efficiency, and convenient equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

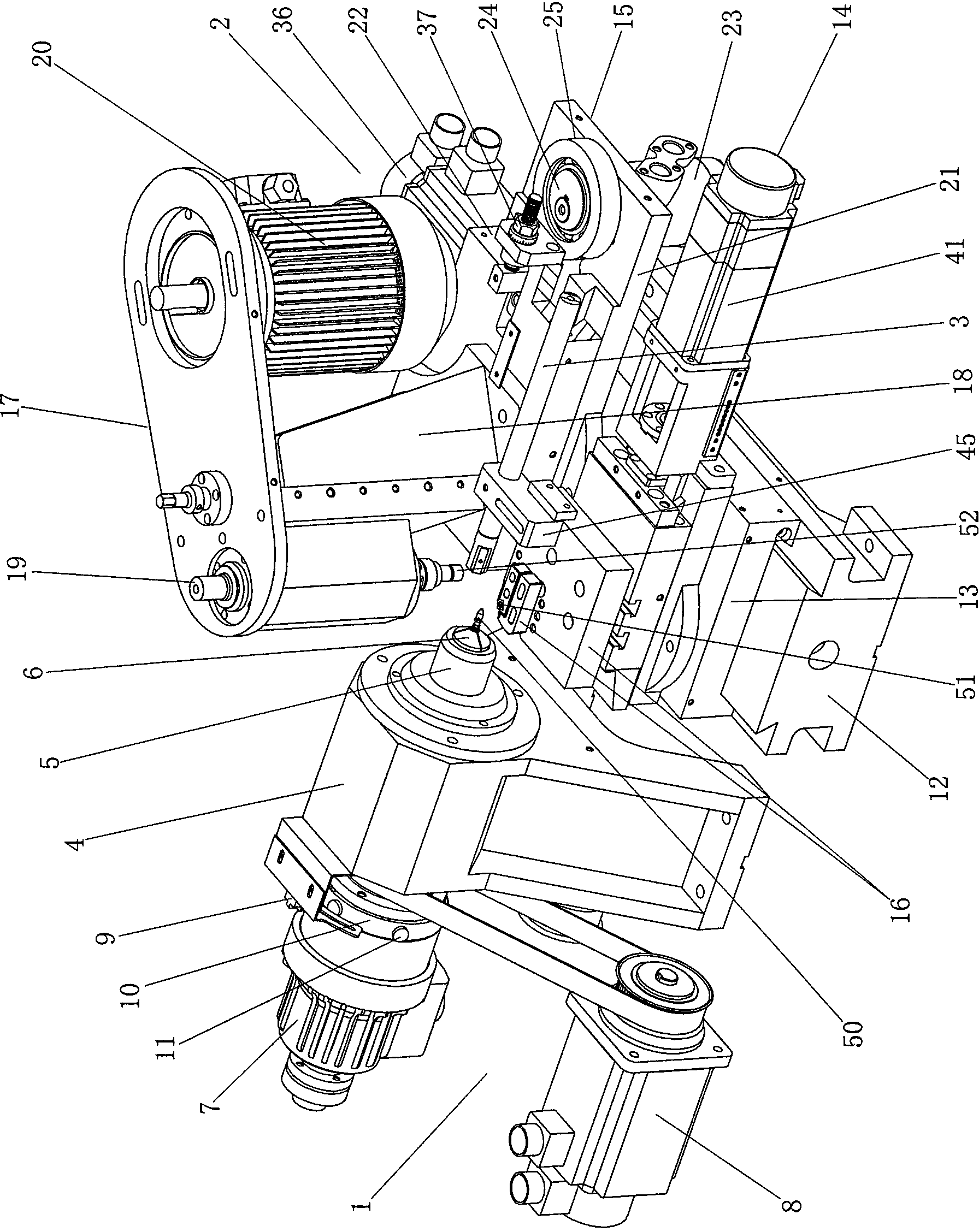

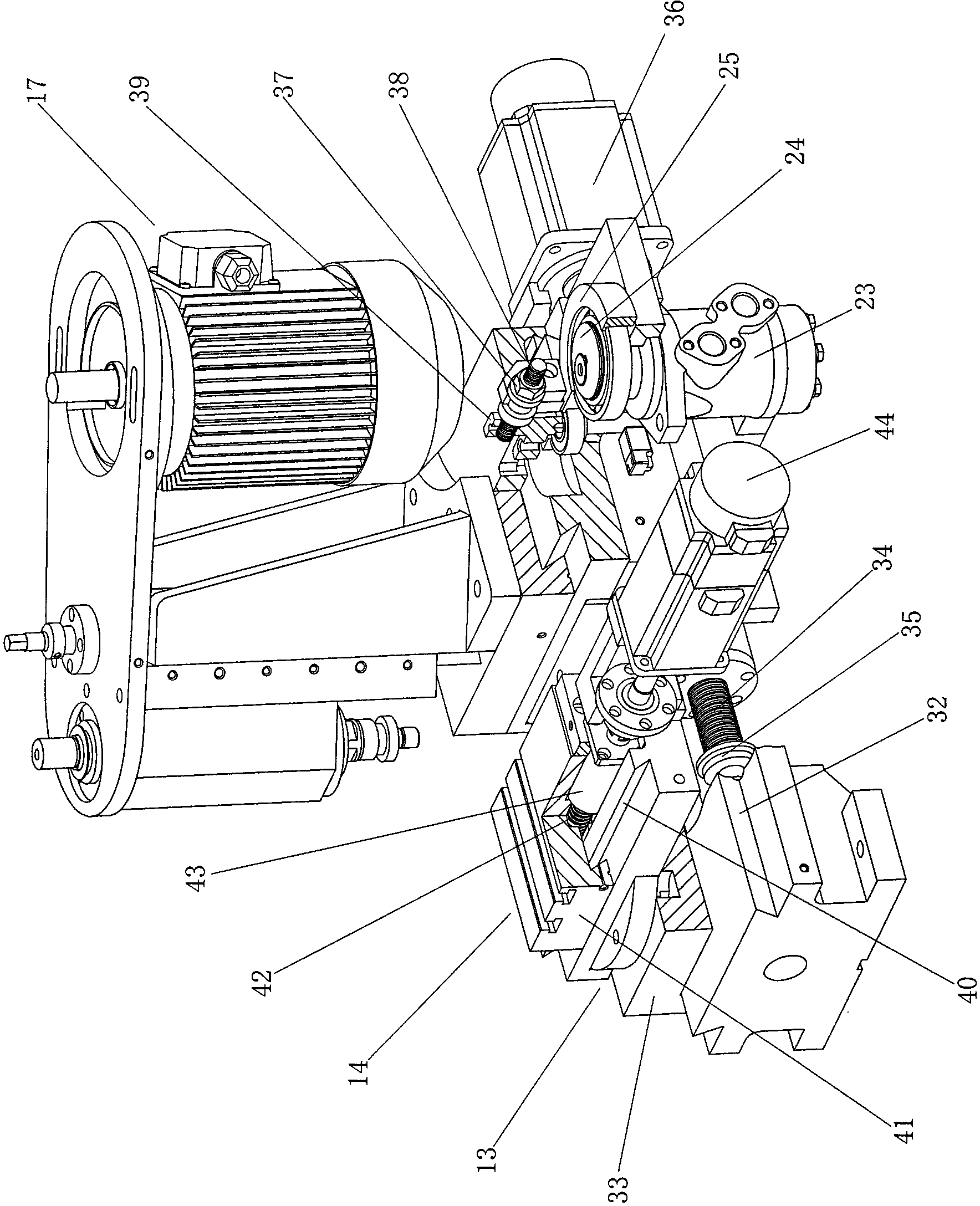

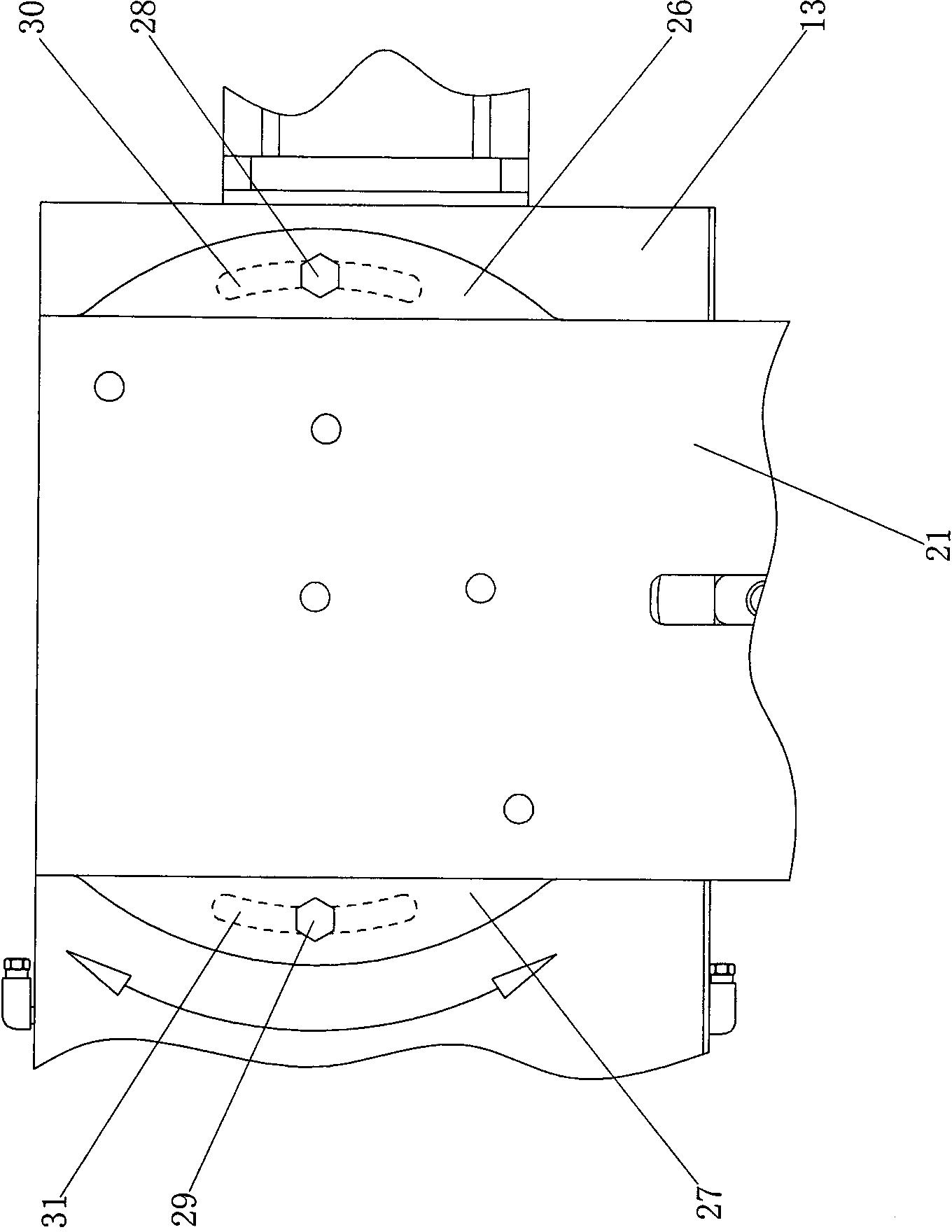

[0021] refer to figure 1 , the universal turning and milling compound automatic processing device for the screwdriver head is characterized in that it includes a clamping fixed-point rotating assembly 1 installed on the machine base, a turning and milling tool compound feeding assembly 2 and a workpiece conveyor 3, wherein the clamping The fixed-point rotating assembly 1 is composed of an assembly seat 4, a hollow main shaft 5 that rotates and fits on the assembly seat 4, a sliding openable collet 6 that fits in the shaft cavity of the hollow main shaft 5 and exposes the front end of the hollow main shaft 5, and is installed and fixed on the assembly The hollow rotary hydraulic cylinder 7 on the base 4 and matched with the sliding collet 6, the servo motor 8 installed on the machine base and drivingly connected with the hollow main shaft 5, and the circumferential fixed-point sensor installed on the assembly base 4 9 and several circumferential fixed-point sensing blocks 11 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com