Production technical method of building gypsum with gradient utilization of thermal energy in condensation and dust removal

A technology of building gypsum and thermal energy, which is applied in the field of building gypsum production technology, can solve the problems of difficult processing of building gypsum production areas, large land occupation, and inability to use low-cost industrial waste heat, etc., to achieve good environmental protection, reduce costs, and achieve zero emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

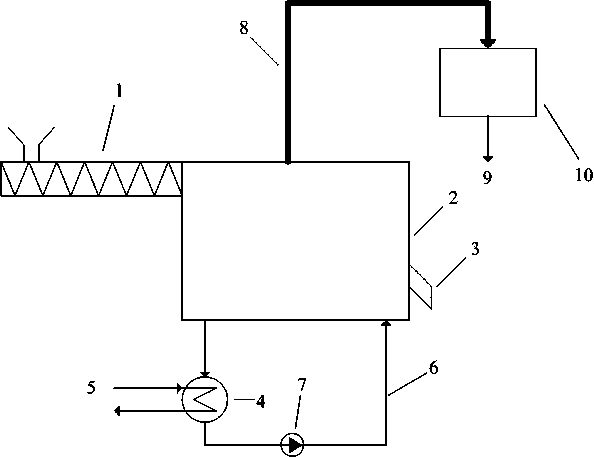

[0013] In the coal-fired power plant with 200,000 units, the processing of industrial gypsum by-products is realized, and the desulfurized gypsum and heat source of the power plant are directly used to produce construction gypsum.

[0014] Gypsum raw materials are directly used for desulfurization gypsum in power plants. The heat source is the 2-stage pumping of the unit as the heat source: steam is taken from the DN50 pipe section in front of the primary drainage door behind the high-row check door. The steam parameters are about 2.0Mpa, 310°C, and the steam condensation temperature is about 210°C.

[0015] Power plant desulfurization gypsum is packed in powder, which can enter the drying and calcination process without crushing.

[0016] As shown in the figure, the gypsum powder containing about 10% free water in the desulfurization gypsum of the power plant is directly transported to the mechanical fluidized drying calciner 2 through the raw material conveyor 1 without bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com