Preparation method of flexible polyester imide enameled wire insulating paint

A technology of enameled wire insulation and polyesterimide, which is applied in the field of preparation of flexible polyesterimide enameled wire insulating varnish, can solve the problems of difficult zero defects, high defect rate between turns of motors, etc., and achieve wide process margin and paint film adhesion Good, scratch-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0060] Embodiments 1-3 Formula of flexible polyesterimide enameled wire insulating varnish

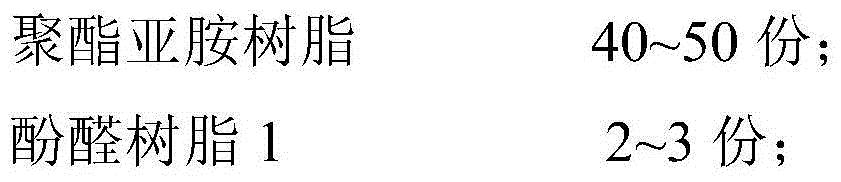

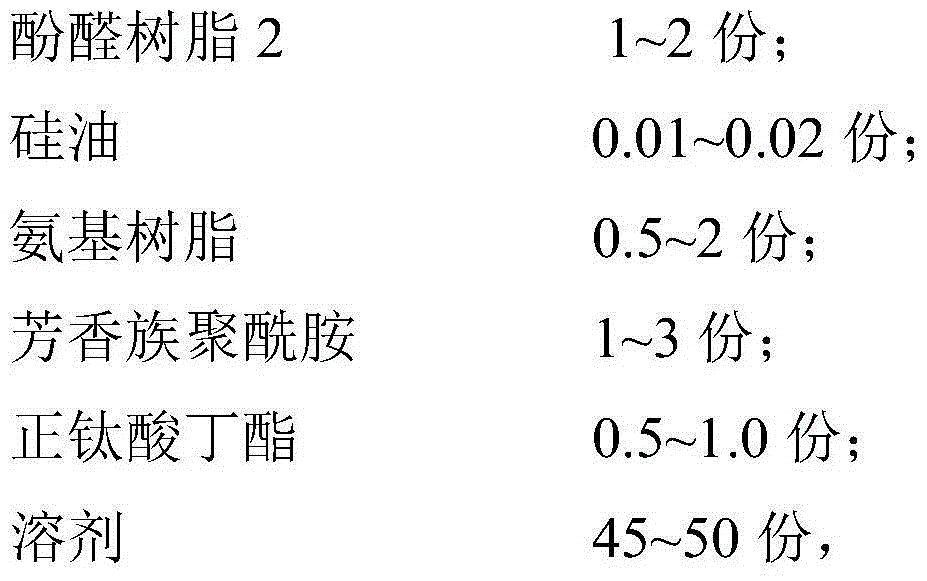

[0061] A flexible polyesterimide enameled wire insulating varnish is characterized in that, in parts by weight, its formula is:

[0062]

[0063] Solvent (cresol: phenol: aromatic hydrocarbon solvent naphtha=50:25:25) 45~50 parts. The specific formula is shown in Table 1.

[0064] Table 1 Recipe

[0065]

Example 1

Example 2

Example 3

Polyesterimide resin

40

45

50

Phenolic resin 1

2

2.5

3

Phenolic resin 2

2

1.5

1

silicone oil

0.01

0.01

0.02

amino resin

0.5

1

2

3

2

1

Butyl orthotitanate

1

0.5

0.5

solvent

48

45

50

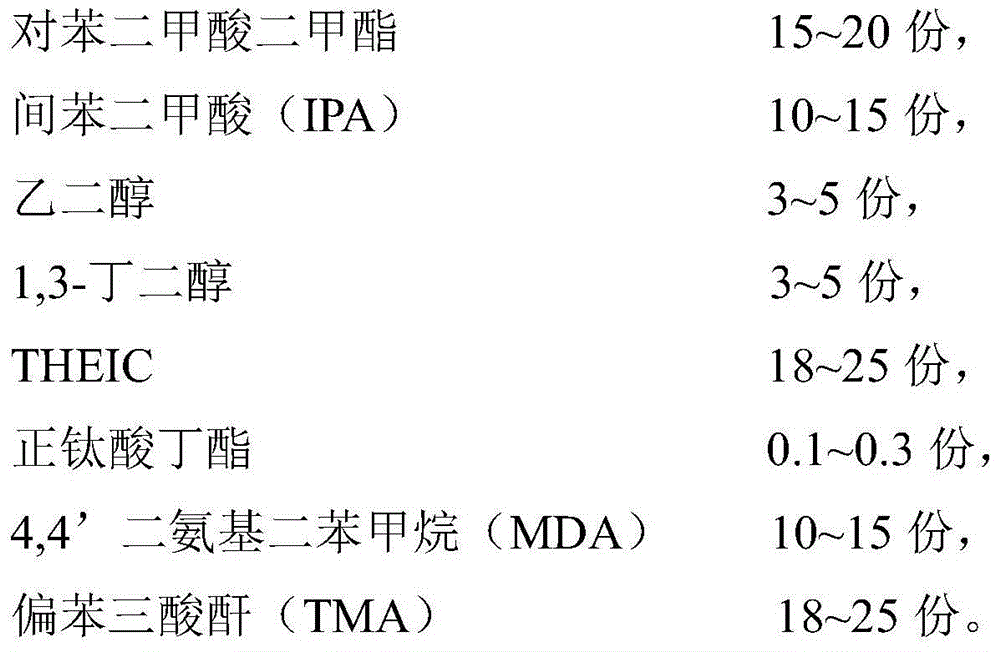

[0066] Wherein, the composition of polyesterimide is:

[0067]

[0068]

[0069] Among them, phenolic resin 1:

[0070]

[0071] A preparation method of a flexible polyesteri...

Embodiment 4

[0090] Example 4 Enameled wire sample wire and detection of flexible polyesterimide enameled wire insulating varnish

[0091] Preparation of enameled wire sample wire:

[0092] Coating equipment: Meida QHLF1 / 2;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com