A flash dryer

A flash dryer and drying cylinder technology, used in dryers, drying solid materials, drying gas layout, etc., can solve the problems of large airflow resistance, filter cake-like and paste-like materials, etc., and achieve airflow resistance. Small, shortened drying time, significant energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

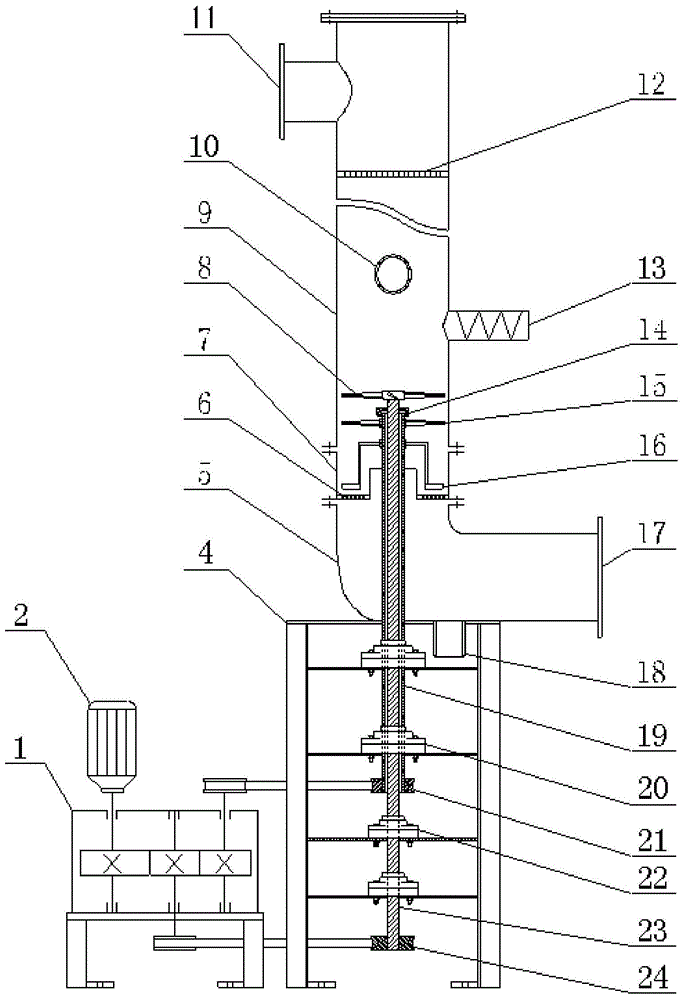

[0029] like figure 1 shown. The flash dryer of the present invention includes a transmission mechanism and a material breaking mechanism, and the material breaking mechanism includes a hollow outer rotating shaft 19 and an inner rotating shaft 23 arranged in the hollow outer rotating shaft 19; it also includes a drying cylinder 9 sequentially connected from top to bottom , sieve plate section tube 7, air inlet tube 5; the transmission mechanism includes an inner shaft drive mechanism and a hollow outer shaft drive mechanism;

[0030] The lower section of the drying cylinder 9 is equipped with an upper blade 8 and a lower blade 15 for breaking up materials;

[0031] The upper blade 8 is connected to the inner shaft 23, and the inner shaft 23 is connected to the inner shaft driving mechanism through the inner shaft pulley 24; the lower blade 15 is connected to the hollow outer shaft 19, and the hollow outer shaft 19 is connected to the hollow outer shaft driving mechanism throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com