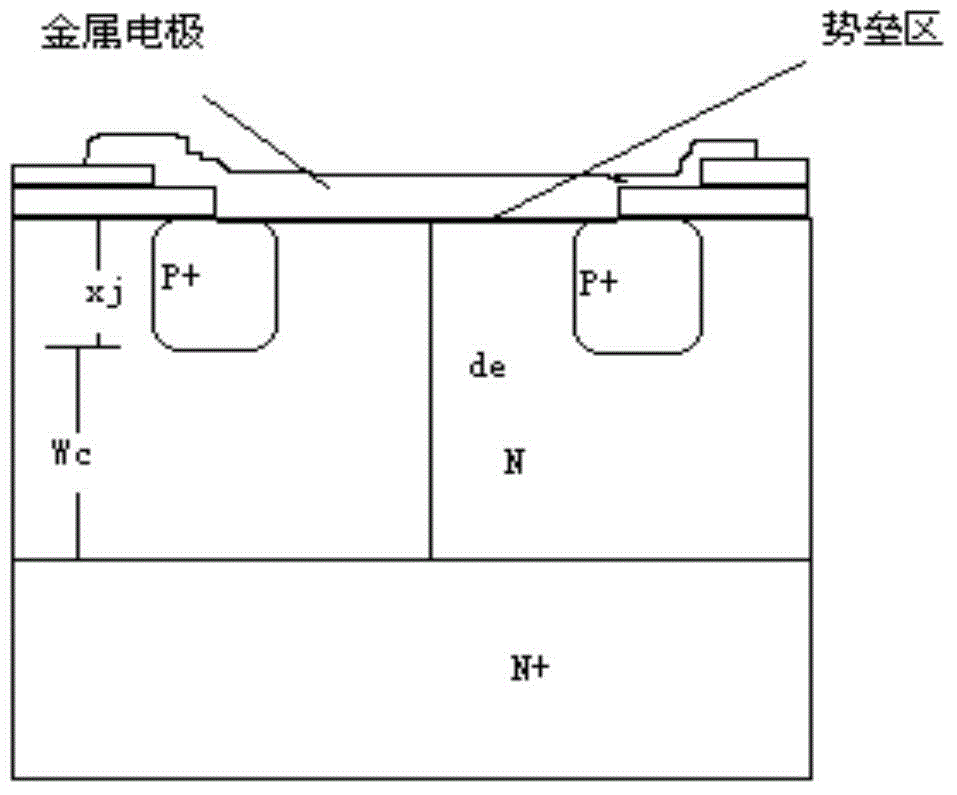

Low-electric-leakage and low-forward-voltage-drop Schottky diode structure and manufacturing method of low-electric-leakage and low-forward-voltage-drop Schottky diode structure

A diode and Schottky potential technology, applied in the field of diodes and their preparation, can solve the problems of increased forward voltage drop, increased leakage current, etc., to reduce forward voltage drop, reduce reverse leakage current, and preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

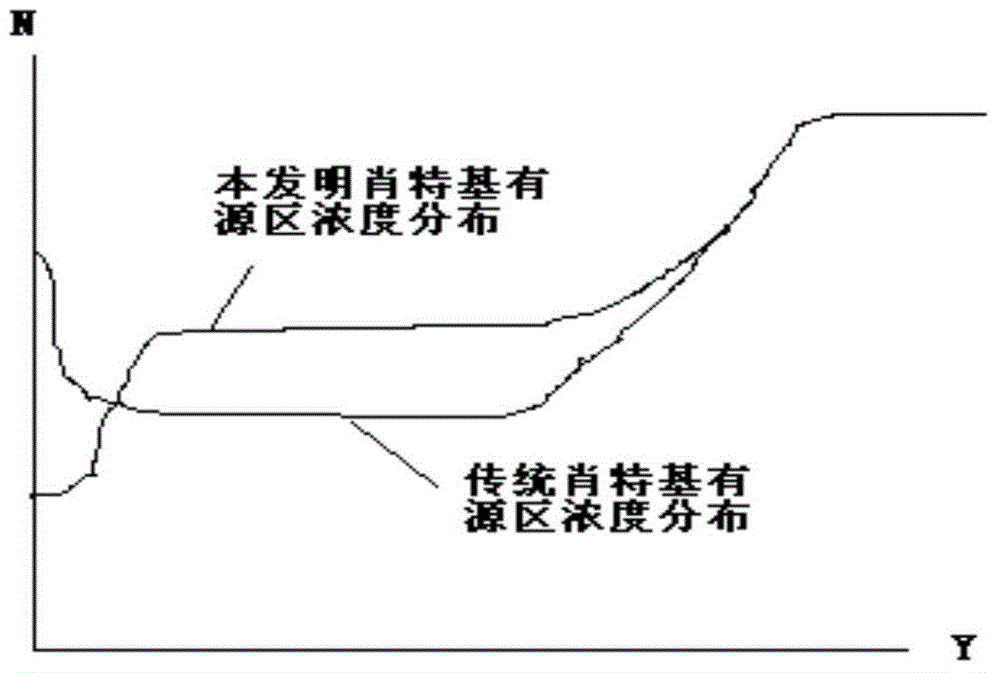

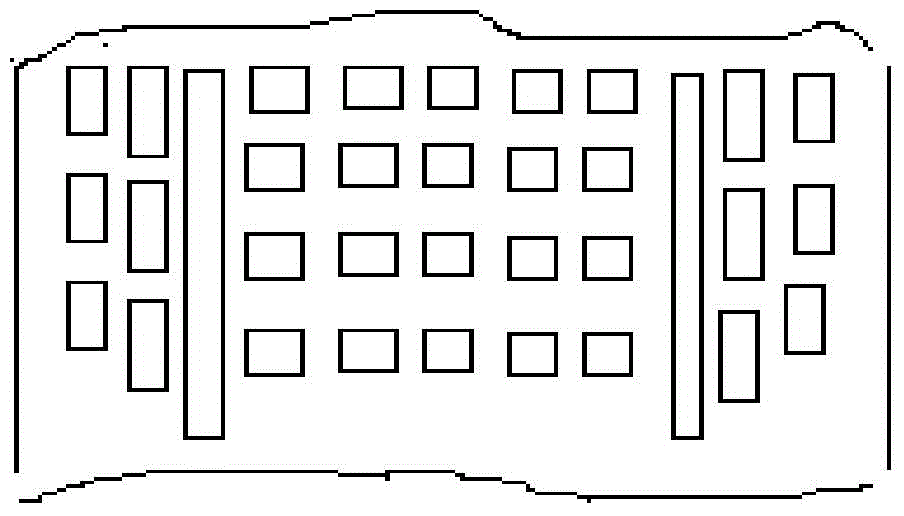

[0037] In this example, the JTE area is divided into three areas, the first area is adjacent to the active area, which is a 100% light transmission area (i.e. full injection), the second area is a 75% light transmission area, and the third area is a 50% light transmission area , the width of each area is 10um, the distance between the light-transmitting areas is 1um, and the active area is a 10% light-transmitting area. The epitaxial wafer is N+ / N type, the resistivity of N type is 0.6Ω.cm, the thickness is 4um, and the implantation dose is 3E12 / cm 2 , push junction temperature is 950℃, 60min, barrier metal is Cr, chip area is 1mm 2 .

[0038] Results: The reverse voltage is 56V (normally 48V), the reverse leakage current is 12uA (normally 35uA), and the forward voltage drop is 0.45V (normally 0.5V).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com