Inverted LED chip with high light emitting efficiency and LED device and manufacturing method of inverted LED chip with high light emitting efficiency

An LED chip and flip-chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of the chip's electrical and thermal conductivity, the influence of light extraction efficiency, the inability to be further improved, and the numerous manufacturing processes, so as to save process steps and manufacturing. cost, reduce material cost and process cost, and improve the effect of light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

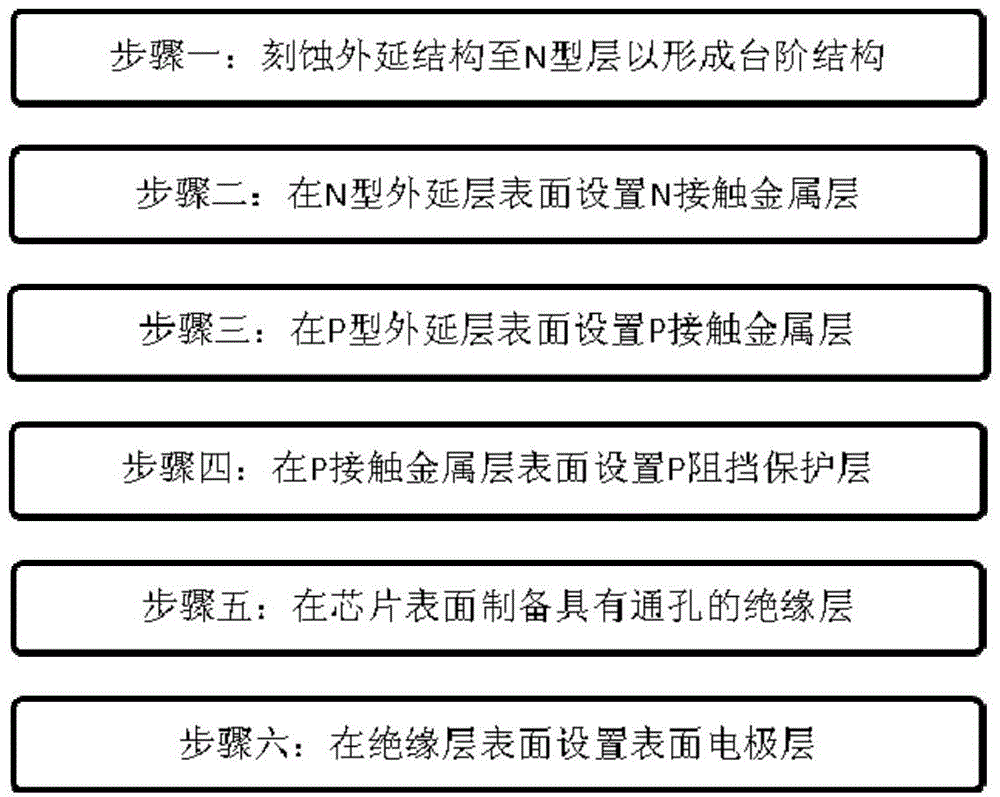

Method used

Image

Examples

Embodiment 1

[0060] This embodiment is an embodiment of flip-chip LED chips.

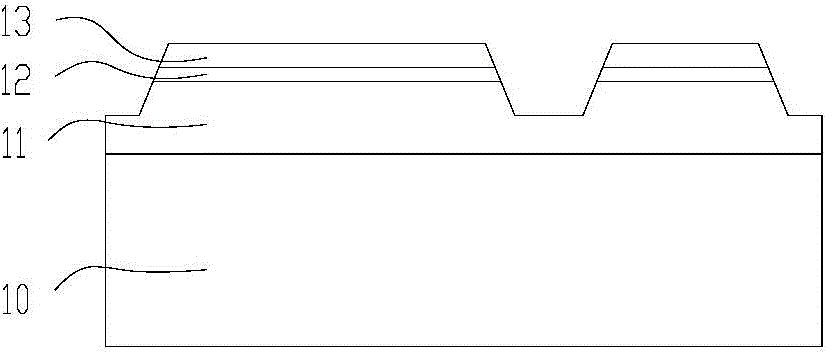

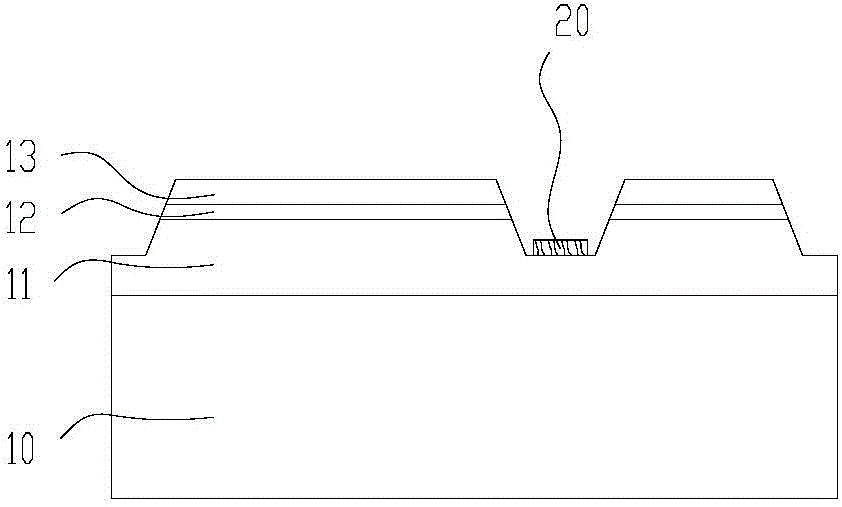

[0061] refer to image 3 , image 3 It is a schematic cross-sectional structure diagram of the flip-chip LED chip of Embodiment 1.

[0062] The flip-chip LED chip 600 of this embodiment includes an epitaxial substrate 100, an N-type epitaxial layer 101 superimposed on the upper surface of the epitaxial substrate layer 100, a light-emitting layer 102 superimposed on the upper surface of the N-type epitaxial layer 101, and a light-emitting layer superimposed on the light-emitting layer 100. P-type epitaxial layer 103 on the upper surface of layer 102 . Wherein, a first concave hole 502 is opened on the upper surface of the P-type epitaxial layer 103, the first concave hole 502 penetrates through the light-emitting layer 102, and extends downward to the N-type epitaxial layer 101, and the first concave hole 502 does not completely penetrate The N-type epitaxial layer 101. A P-contact metal layer 201 is stacked ...

Embodiment 2

[0068] see Figure 5 , this embodiment is an embodiment of an LED device formed by flip-chip mounting the flip-chip LED chip 600 on the substrate 300 in Embodiment 1.

[0069] see Figure 5, which is a schematic structural diagram of the LED device of this embodiment. The LED device includes a substrate 300 and a flip-chip LED chip 600 flip-chip mounted on the substrate 300 . The flip-chip LED chip is the flip-chip LED chip provided in Embodiment 1. The substrate 300 is provided with P electrodes 301 and N electrodes 302 spaced apart from each other, and the P surface electrodes 204 and N surface electrodes 205 of the flip-chip LED chip 600 are respectively connected to the P electrodes 301 and N electrodes 302 on the substrate 300 for connection. The method is an existing method in the technical field such as reflow soldering, ultrasonic thermocompression welding, or pasting with conductive adhesive. More preferably, the substrate 300 is provided with a third through hole...

Embodiment 3

[0073] see Figure 6 , this embodiment is an embodiment of an LED device formed by flip-chip mounting the flip-chip LED chip 600 on the substrate 400 in Embodiment 1.

[0074] see Figure 6 , which is a schematic structural diagram of the LED device of this embodiment. The LED device includes a substrate 400 and at least one flip-chip LED chip 600 provided in Embodiment 1. The surface of the substrate 400 is provided with a plurality of substrate electrodes 401 , and adjacent substrate electrodes 401 are spaced apart. The substrate electrode 401 is used for electrical connection with the flip-chip LED chip 600 and external devices. Specifically, when the flip-chip LED chip 600 is flip-chip connected to the substrate 400 , its P surface electrode 204 and N surface electrode 205 are respectively connected to two adjacent substrate electrodes 401 .

[0075] Through the electrical connection of the substrate electrodes 401, a plurality of flip-chip LED chips 600 will form a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com