Aluminum-based copper-clad plate and manufacturing method thereof, and electronic circuit board

A technology of aluminum-based copper-clad laminates and aluminum substrates, which is applied in the manufacture of printed circuits, electrical components, and printed circuits, can solve problems such as reduced heat dissipation capacity, electrified substrates, and safety issues, and achieve improved heat dissipation performance, improved reliability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

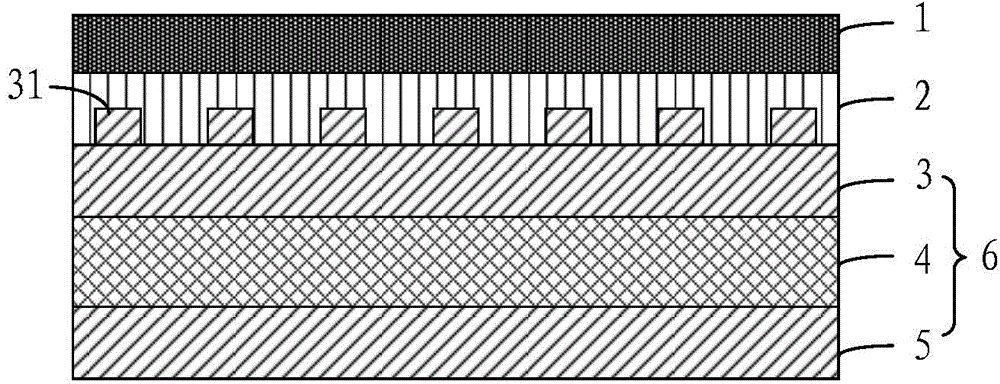

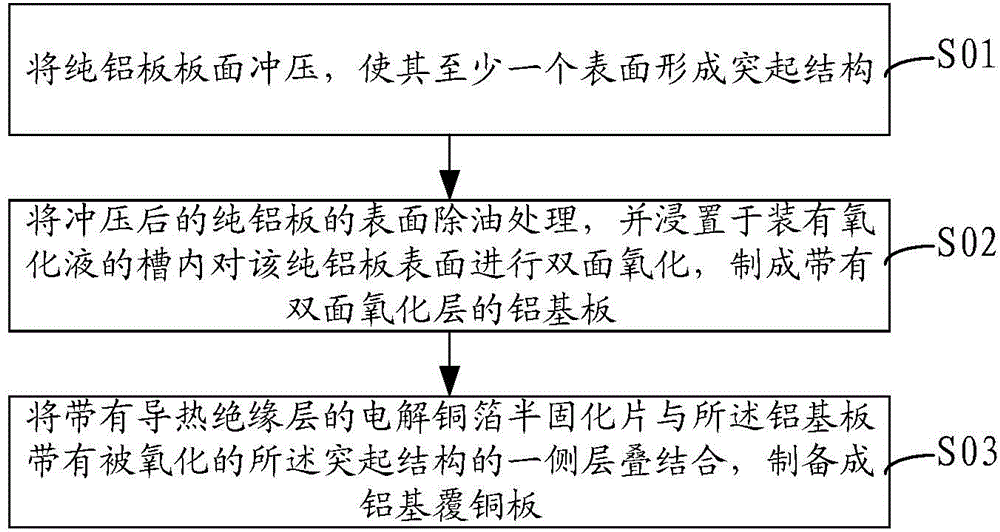

[0025] Correspondingly. The invention also provides a method for preparing an aluminum-based copper-clad laminate with simple procedures and high production efficiency. This method can be used to prepare the above as figure 1 As shown in the aluminum base copper clad laminate, the process of the method is as follows figure 2 As shown, it includes the following steps:

[0026] Step S01. Stamping the surface of the pure aluminum plate to form a protrusion structure 31 on at least one surface of the pure aluminum plate;

[0027] Step S02. Degreasing the surface of the stamped pure aluminum plate, immersing it in a tank filled with an oxidizing solution to oxidize the surface of the pure aluminum plate on both sides to produce an aluminum substrate 6 with double-sided aluminum oxide layers. Specifically, refer to figure 1 The oxidized aluminum substrate 6 includes a first aluminum oxide layer 3 , a pure aluminum layer 4 and a second aluminum oxide layer 5 stacked in sequence,...

Embodiment 1

[0033] An aluminum-based copper-clad laminate for preparing electronic circuit boards and a preparation method thereof.

[0034] The structure of the aluminum base copper clad laminate is as follows figure 1 As shown, it includes a copper foil layer 1, a thermally conductive insulating layer 2, a first aluminum oxide layer 3, a pure aluminum layer 4, and a second aluminum oxide layer 5 arranged in sequence; wherein, the first aluminum oxide layer 3 and the thermally conductive insulating layer 2 The contact side has a protruding structure 31, and the height of the protruding structure 31 is 5 μm.

[0035] The preparation method of the above-mentioned aluminum-based copper-clad laminate is as follows:

[0036] (1) Stamping the surface of the 1100 series pure aluminum plate to form a protruding structure 31 on one of the surfaces;

[0037] (2), degreasing the surface of the stamped 1100 series pure aluminum plate, immersing it in a tank filled with an oxidizing solution to oxi...

Embodiment 2

[0040] An aluminum-based copper-clad laminate for preparing electronic circuit boards and a preparation method thereof.

[0041] The structure of the aluminum-based copper-clad laminate is the same as that of the aluminum-based copper-clad laminate in Embodiment 1. The differences are as follows: 1. The pure aluminum plate adopts 5052 series; 2. The height of the protruding structure 31 on the first alumina layer 3 is 10 μm; 3. The thermal conductivity of the thermally conductive insulating layer 2 is 3W / mK.

[0042] Refer to Example 1 for the preparation method of the above-mentioned aluminum-based copper-clad laminate.

[0043] In addition, an electronic circuit board comprising the above-mentioned aluminum-based copper-clad laminate is also provided.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com