Powdered sealing agent, and sealing method

A powder, sealant technology, applied in chemical instruments and methods, adhesives, electrical components, etc., can solve problems such as damage to equipment reliability and easy damage to electronic components, so as to achieve the effect of not damaging reliability and preventing weather resistance deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

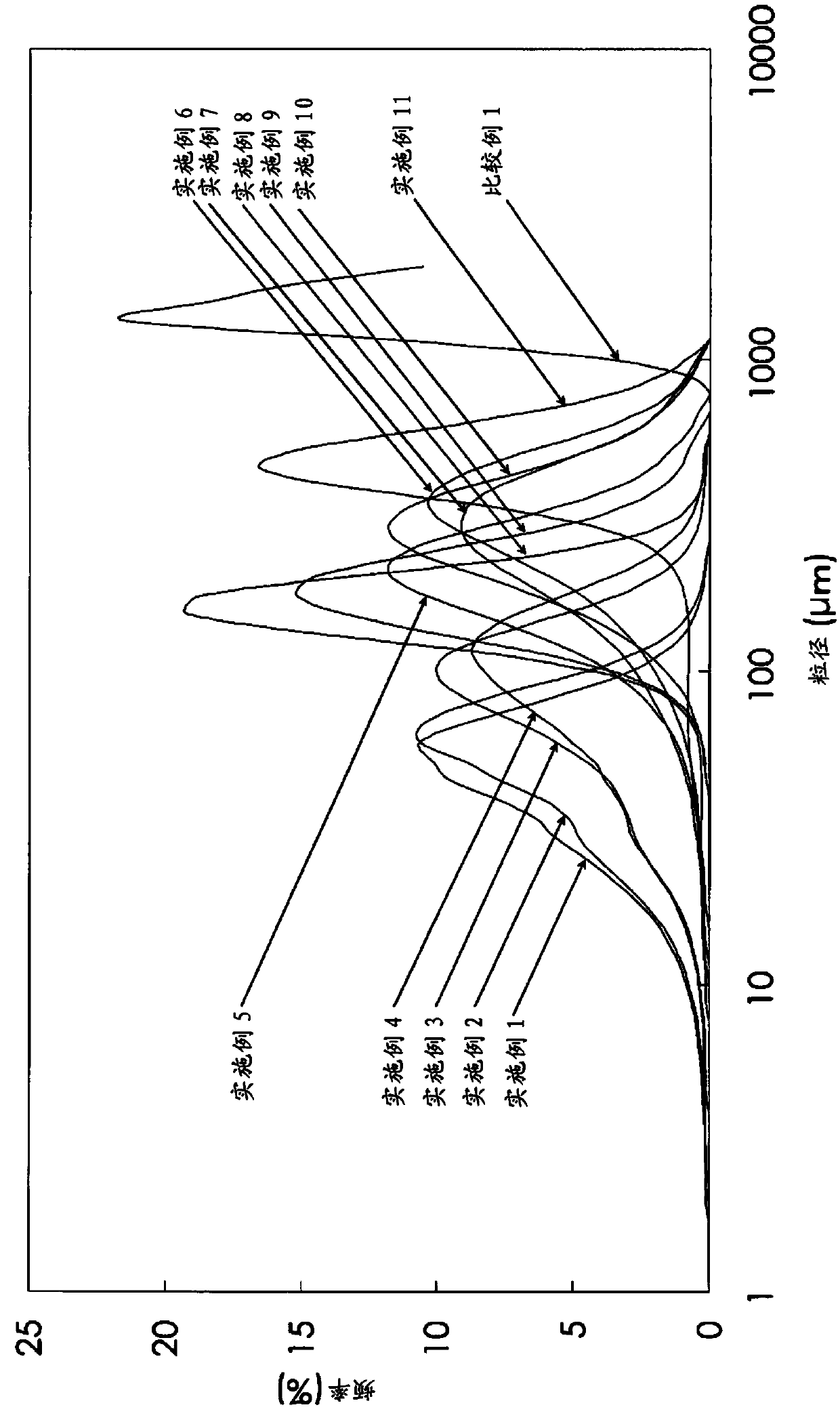

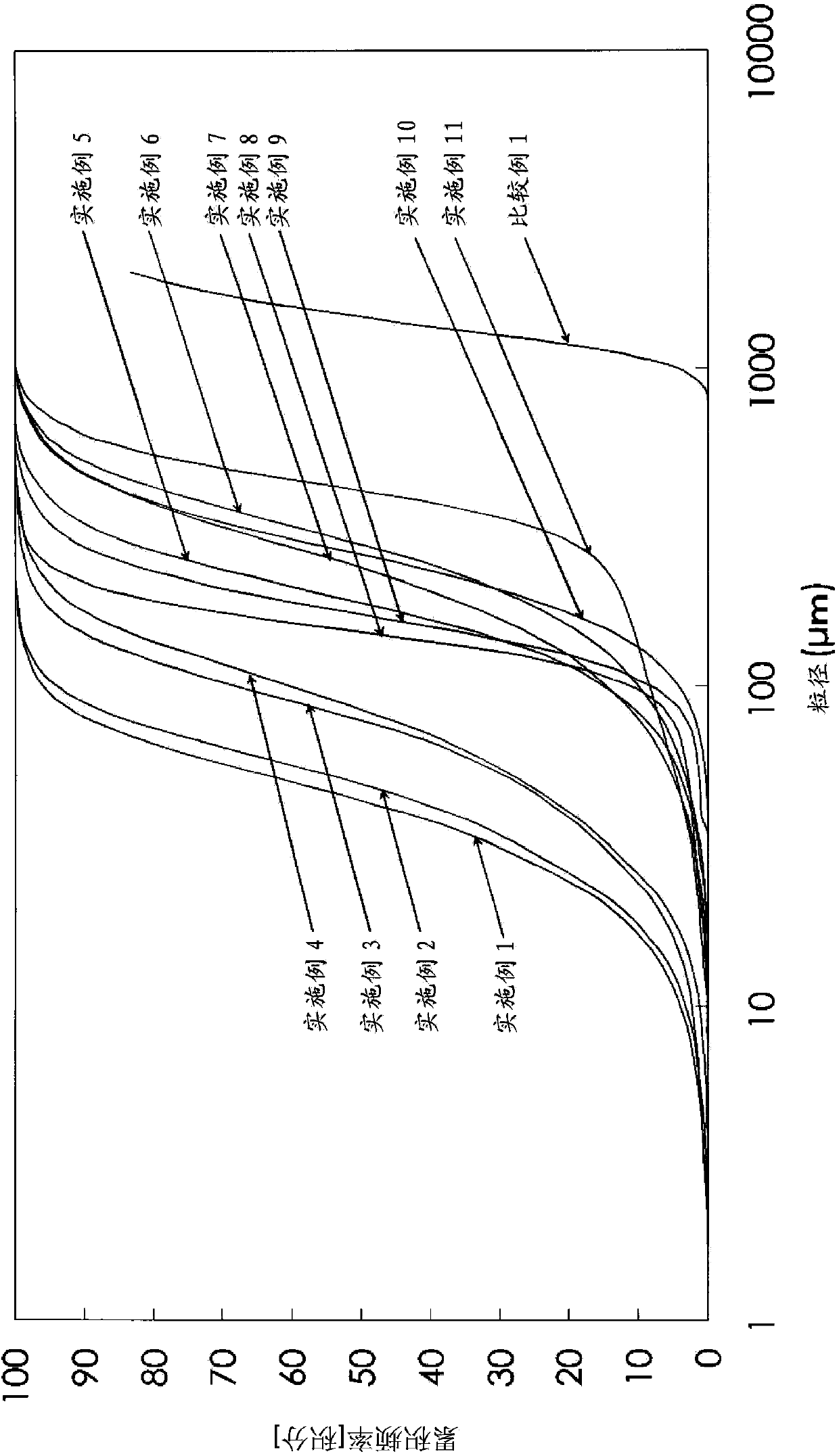

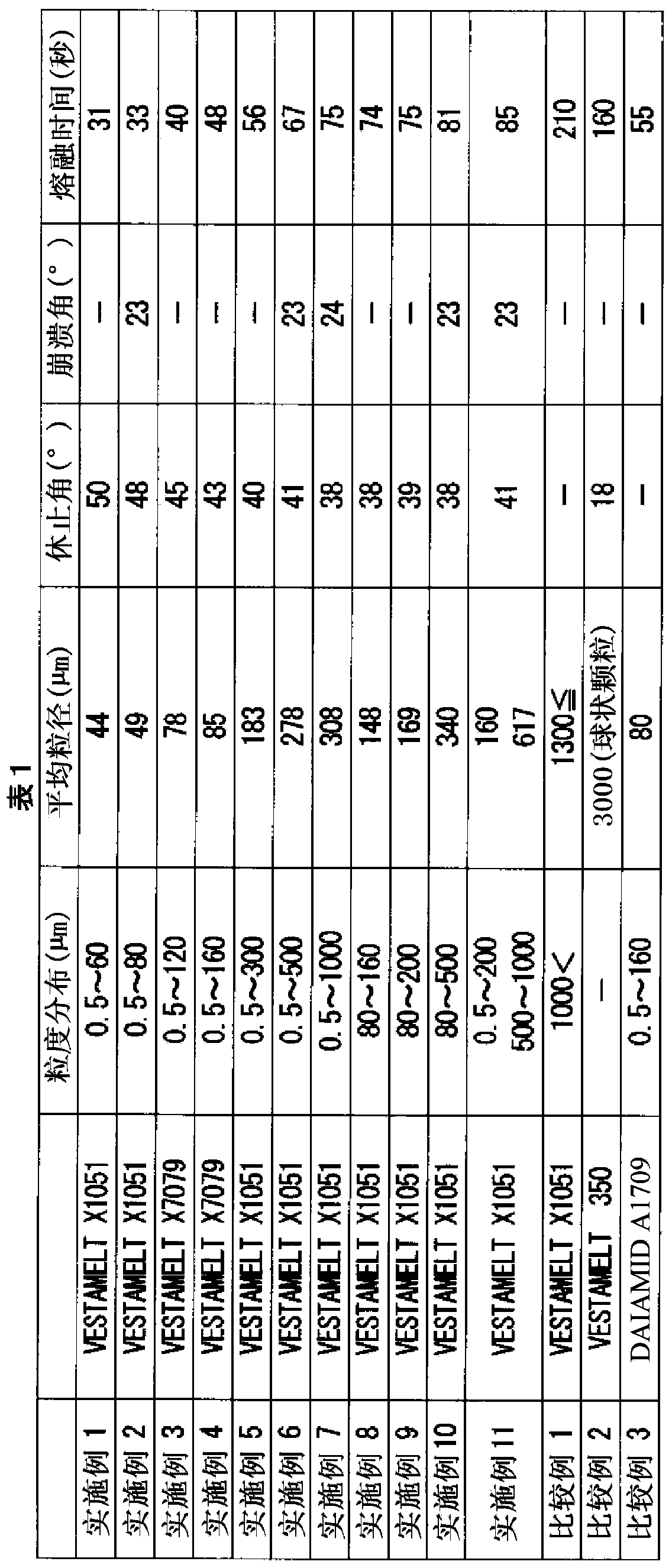

[0135] For copolyamide (VESTAMELT X1051, manufactured by Evonik, containing C 10-14 Alkylene, melting point 130°C (DSC), melt flow rate 15g / 10min (temperature 160°C and load 2.16kg)) were frozen and pulverized, and classified using a metal mesh with a pore size of 60μm to obtain an average particle size of 44μm, particle size 0.5 ~ 60μm powder resin particles. After using a metal mesh (hole size: 200μm), the resin particles are uniformly dispersed on an electronic substrate (200mm×200mm) made of glass epoxy resin, and heated in an atmosphere at a temperature of 170°C to obtain a transparent resin. coated substrate.

Embodiment 2

[0137] Copolyamide (VESTAMELT X1051) was frozen and pulverized, and classified using a metal mesh with a pore size of 80 μm to obtain powdered resin particles with an average particle diameter of 49 μm and a particle size of 0.5 to 80 μm. After the resin particles are uniformly spread on the electronic substrate (200mm×200mm) made of glass epoxy resin using a metal mesh (pore size of 200μm), it is heated in an atmosphere at a temperature of 170°C to obtain a transparent resin substrate. coated substrate.

Embodiment 3

[0139] For copolyamide (VESTAMELT X7079, manufactured by Evonik, containing C 10-14 Alkylene, melting point 130°C (DSC), freeze pulverization at a melt flow rate of 3g / 10min (temperature 160°C and load 2.16kg), and classify using a metal mesh with a pore size of 120µm to obtain an average particle size of 78µm, Powdered resin particles with a particle size of 0.5-120 μm. After the resin particles are evenly spread on the electronic substrate (200mm×200mm) made of glass epoxy resin using a metal mesh (pore size of 250μm), it is heated in an atmosphere at a temperature of 170°C to obtain a transparent resin substrate. coated substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com