Water-based coolant

A coolant and water system technology, applied in the directions of additives, quenching agents, heat treatment equipment, etc., can solve the problems of long steam film stage and uneven cooling, and achieve the effect of high cooling performance and not easy to corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13、 comparative example 1~8

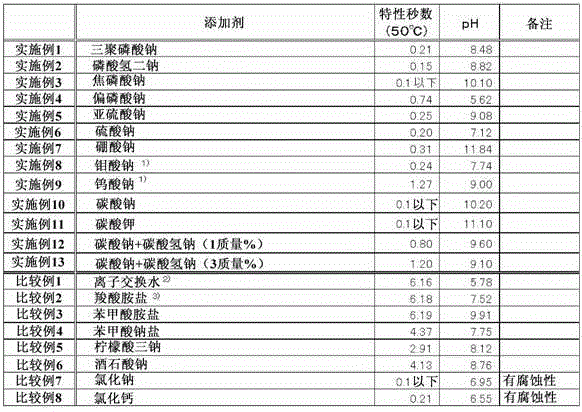

[0040] As shown in Table 1, various additives (inorganic acid salts, etc.) were dissolved in ion-exchanged water to prepare a water-based coolant as a sample solution. The concentrations of the additives were all set to 10% by mass based on the sample solution unless otherwise specified. In Examples 12 and 13, sodium bicarbonate was added in an amount exactly as described in Table 1.

[0041] Keep each sample solution at 50°C, conduct a cooling test according to JIS K2242B method, and measure the characteristic seconds

[0042] number. Specifically, the time (number of seconds) until the cooling curve reaches the temperature (characteristic temperature) at which the vapor film stage ends is measured. The results are shown in Table 1. In addition, the pH of each aqueous solution is also described in Table 1 together.

[0043] [Table 1]

[0044]

[0045] 1) The additive concentration was set to 5% by mass. the

[0046] 2) No additives. the

[0047] 3) 30% by mass of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com