Polypropylene composition and preparation method and application thereof

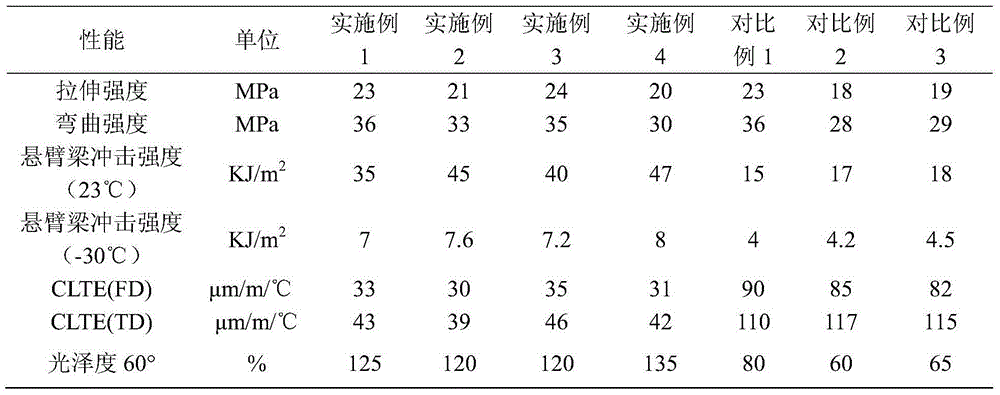

A polypropylene composition and polypropylene resin technology, applied in the field of polymer material technology and science, can solve the problems of lack of surface gloss and low temperature resistance of parts, and achieve high low temperature impact resistance, high gloss, low temperature and so on. Effect of Coefficient of Linear Expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

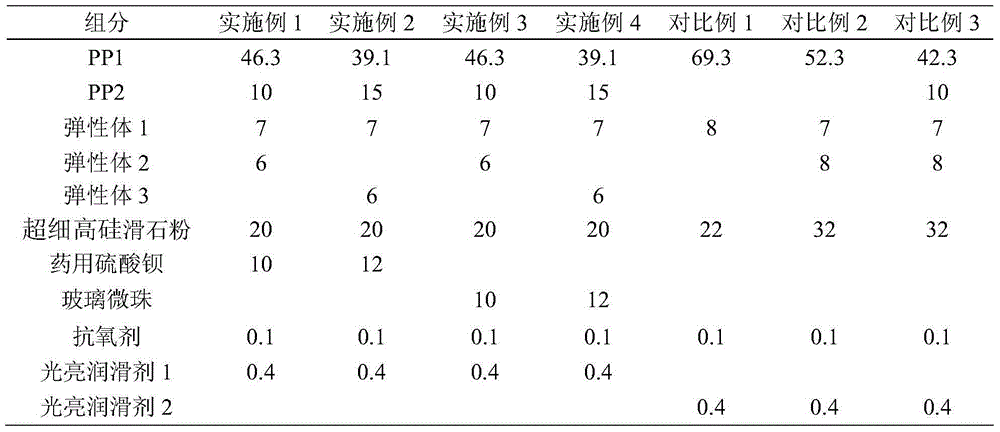

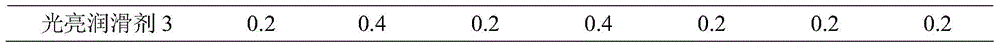

[0045] Present embodiment is shown in Table 1 by each raw material formula of polypropylene composition, and its preparation method is to carry out as follows:

[0046] Add polypropylene resin, elastomer, medicinal barium sulfate, superfine high-silicon talc powder, bright lubricant and other additives (antioxidants) to a high-speed mixer and mix for 5 minutes at a mixing speed of 1000r / min, and then pass through a double The screw extruder performs melt blending. The aspect ratio of the twin-screw extruder is 35:1. The processing temperature of the twin-screw extruder is 170°C, 180°C, 190°C, and 190°C from the feeding port to the die mouth. , 190°C, 200°C, 200°C, 200°C, 200°C, 200°C, 210°C, the vacuum degree is 0.6MPa.

[0047] After melting and blending, water-cooling, air-drying, and pelletizing steps, the polypropylene composition with low linear expansion coefficient, high cold resistance and high gloss is obtained.

Embodiment 2

[0049] The present embodiment is shown in Table 1 according to each raw material formula of polypropylene composition, and its preparation process is the same as embodiment 1

Embodiment 3

[0051] The present embodiment is shown in Table 1 according to each raw material formula of polypropylene composition, and its preparation process is the same as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com