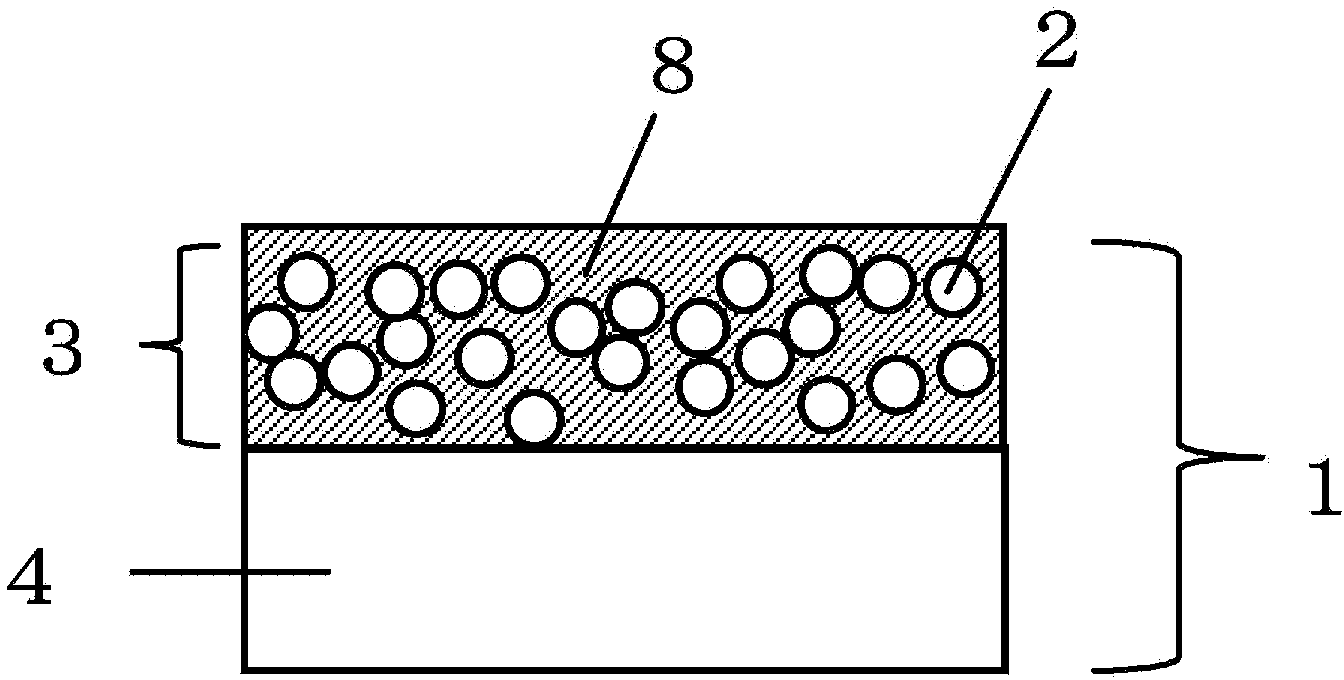

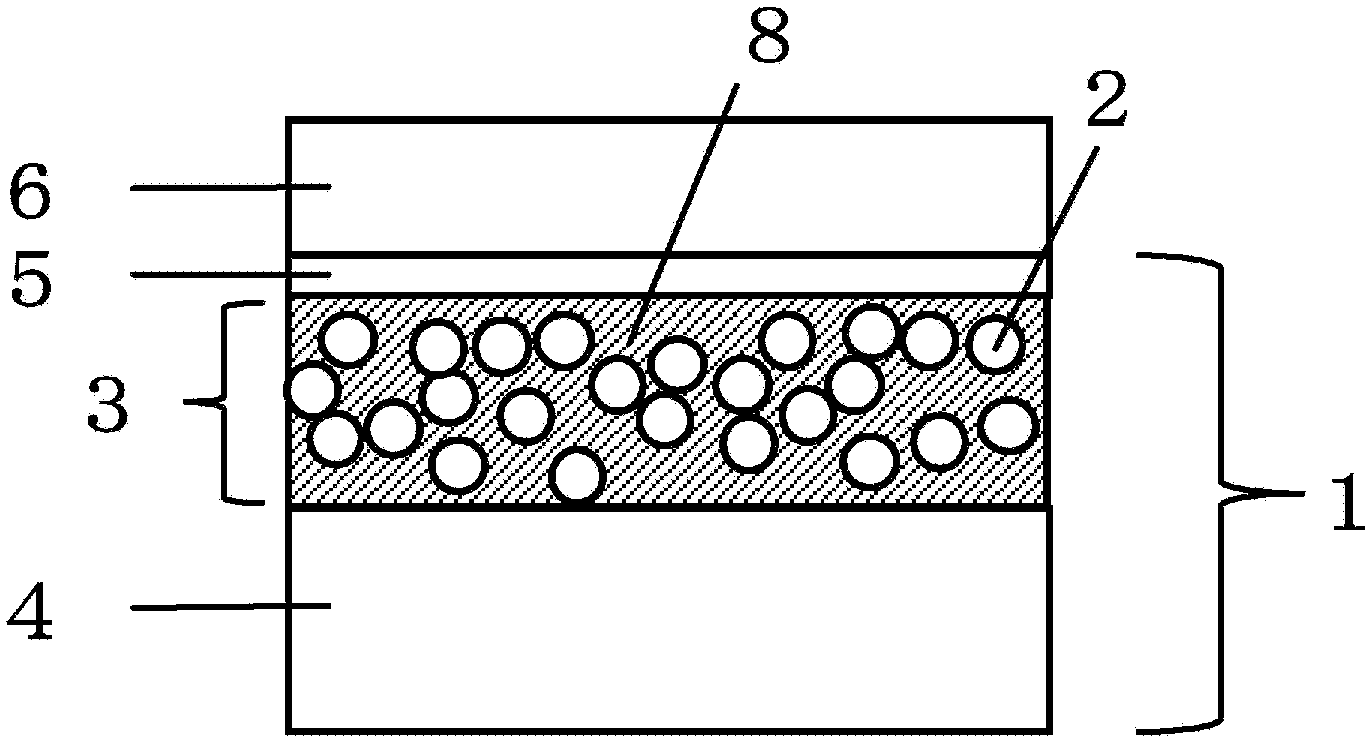

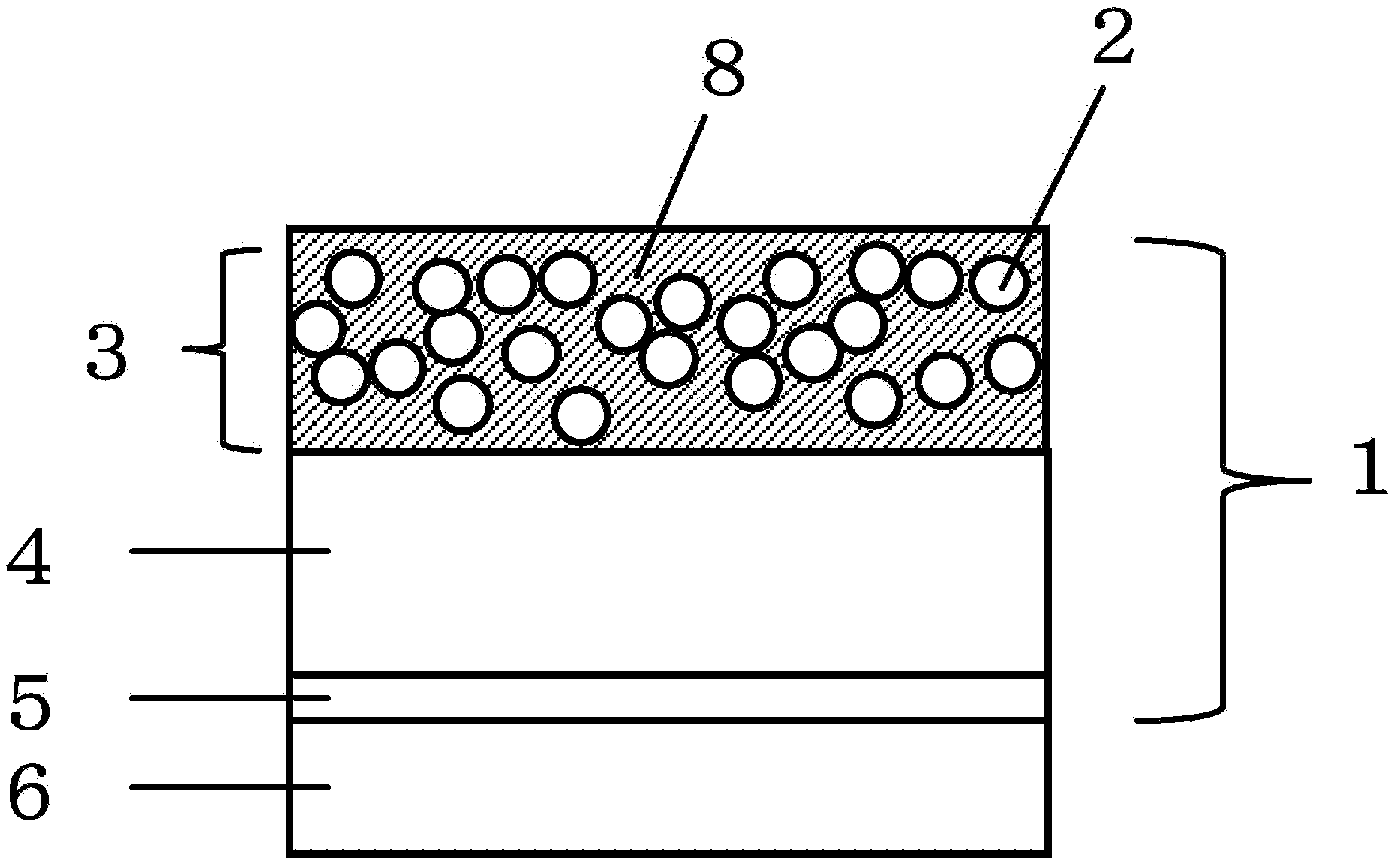

Transmissive type screen

A transmissive screen technology, applied in TV, color TV, projection devices, etc., can solve the problems of non-transmissive screen use, screen opacity, etc., achieve uneven brightness and hot spot improvement, high image brightness, and field of view angle broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Using a slide bead coating device, the coating amount of solid content is 18.5g / m 2 A light-diffusing layer coating liquid 1 of the following composition was coated on one side of a transparent polyethylene terephthalate film (haze value 4%) with a thickness of 100 μm, blown with cold air at 10° C., and then Drying was performed by blowing hot air at 50° C. to produce the transmissive screen of Example 1. It should be noted that the void volume was 17 ml / m as measured using a mercury porosimeter (Autopore II 9220 manufactured by Micromeritics Instrument Corporation). 2 . The cross-section of the light-diffusing layer was observed with an electron microscope, and its thickness was measured to be 27 µm, and the porosity calculated from the above value was 64%. In addition, the specific surface area of the light-diffusing particles per unit area of the screen calculated from the average primary particle size and specific gravity is 4.2m 2 / m 2 .

[0094]

[0095...

Embodiment 2

[0108] A transmissive screen of Example 2 was produced in the same manner as in Example 1 except that the light-diffusing layer coating solution 1 of Example 1 was replaced with the following light-diffusing layer coating solution 2 . It should be noted that, according to the same operation as in Example 1, the measured porosity was 52%, and the specific surface area of the light-diffusing particles per unit area of the screen calculated from the average primary particle diameter and specific gravity was 4.2m. 2 / m 2 .

[0109]

[0110] 100 parts of silica dispersion 1 (calculated as silica solid content)

[0111] 60 parts of polyvinyl alcohol

[0112] (saponification degree 88%, average polymerization degree 3500)

[0113] 4 parts boric acid

[0114] 0.3 parts of nonionic surfactant

[0115] (polyoxyethylene alkyl ether)

[0116] Light-diffusing particles 7.2 parts

[0117] (OPTBEADS 500S)

[0118] The total solid content concentration was adjusted to 12% with w...

Embodiment 3

[0120] A transmissive screen of Example 3 was produced in the same manner as in Example 1 except that the light-diffusing layer coating solution 1 of Example 1 was replaced with the following light-diffusing layer coating solution 3 . It should be noted that, according to the same operation as in Example 1, the measured porosity was 49%, and the specific surface area of the light-diffusing particles per unit area of the screen calculated from the average primary particle diameter and specific gravity was 4.2m. 2 / m 2 .

[0121]

[0122] 100 parts of silica dispersion 1 (calculated as silica solid content)

[0123] 70 parts of polyvinyl alcohol

[0124] (saponification degree 88%, average polymerization degree 3500)

[0125] 4 parts boric acid

[0126] 0.3 parts of nonionic surfactant

[0127] (polyoxyethylene alkyl ether)

[0128] Light-diffusing particles 7.6 parts

[0129] (OPTBEADS 500S)

[0130] The total solid content concentration was adjusted to 12% with wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com