Charge-transporting varnish

一种电荷传输性、电荷传输的技术,应用在电路、电气元件、导电涂料等方向,能够解决没有清漆等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0149] The following examples and comparative examples are given to describe the present invention more specifically, but the present invention is not limited to the following examples. In addition, the apparatuses used in the examples are as follows.

[0150] (1) Viscosity

[0151] Device: TVE-22L viscometer manufactured by Toki Sangyo Co., Ltd.

[0152] Measuring temperature: set the constant temperature tank of the viscometer at 25°C for measurement

[0153] (2) surface tension

[0154] Device: Automatic surface tensiometer CBVP-Z manufactured by Kyowa Interface Science Co., Ltd.

[0155] Measurement temperature: measured at an ambient temperature of 23°C

[0156] (3) Film production

[0157] Equipment: Slot die coater T2 manufactured by Techno-machine Co., Ltd.

[0158] (4) Film thickness measurement

[0159] Device: Kosaka Laboratories Co., Ltd. Micro Shape Measuring Machine Surfcorder ET-4000

[0160] (5) Substrate washing

[0161] Equipment: Substrate cleaning ...

Synthetic example 1

[0163] [Synthesis Example 1] Synthesis of Aniline Derivatives

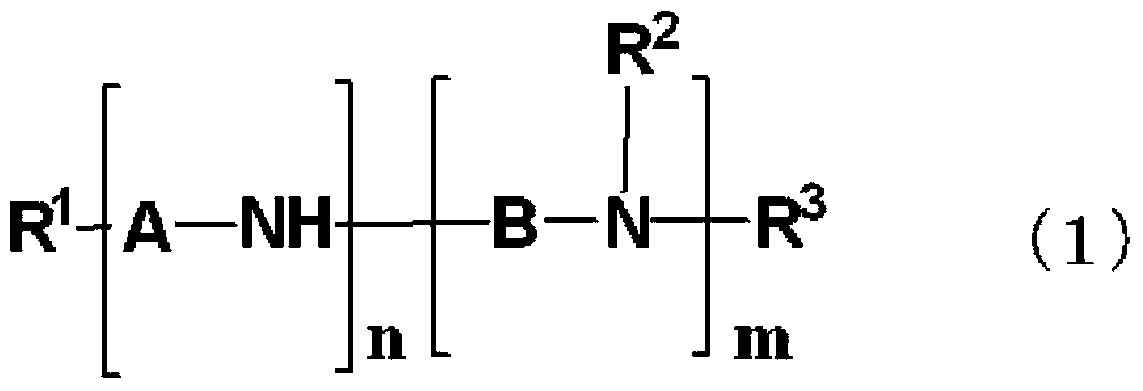

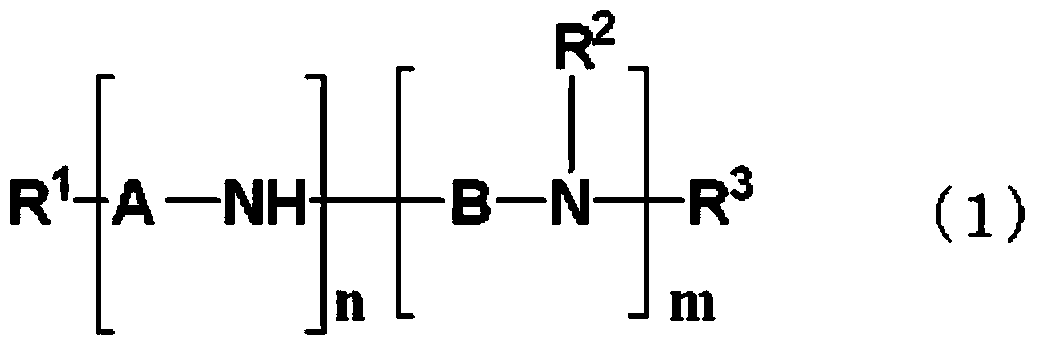

[0164] Based on the description of International Publication No. 2008 / 129947, the oligoaniline derivative represented by the formula (6) used in the examples was synthesized according to the following reaction formula (hereinafter abbreviated as BDPA-PTA). The obtained oligoaniline compound is carried out 1 The results of the H-NMR measurement are shown below.

[0165] 1 H-NMR (CDCl 3 ): δ7.83(S,2H), 7.68(S,1H), 7.26-7.20(m,8H), 7.01-6.89(m,28H)

[0166]

[0167] [2] Preparation of varnish and production and evaluation of film

Embodiment 1

[0169] Under a nitrogen atmosphere, the phenyltetraphenylamine shown in formula (5) (hereinafter referred to as PTA) 1.056g (2.385mmol) and naphthalene disulfonic acid oligomer (hereinafter referred to as NSO-2) 3.230g (3.578mmol) shown in formula (8) are completely dissolved in N,N-dimethyl Acetamide (hereinafter abbreviated as DMAc) 189g.

[0170] To the obtained solution, 21 g of 2,3-butanediol (hereinafter abbreviated as 2,3-BD) was added and stirred as a poor solvent to prepare a charge-transporting varnish (solid content: 2.0% by mass).

[0171] [chemical 9]

[0172]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com