Green tea processing method

A processing method and technology for green tea, applied in the direction of tea treatment before extraction, etc., can solve the problems of leaf vein cell damage of fresh tea leaves, inconsistent product appearance and color requirements, affecting the chlorophyll content of dry tea leaves, etc., to improve quality and economic value, tea soup The taste is sweet and fresh, and the effect of increasing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

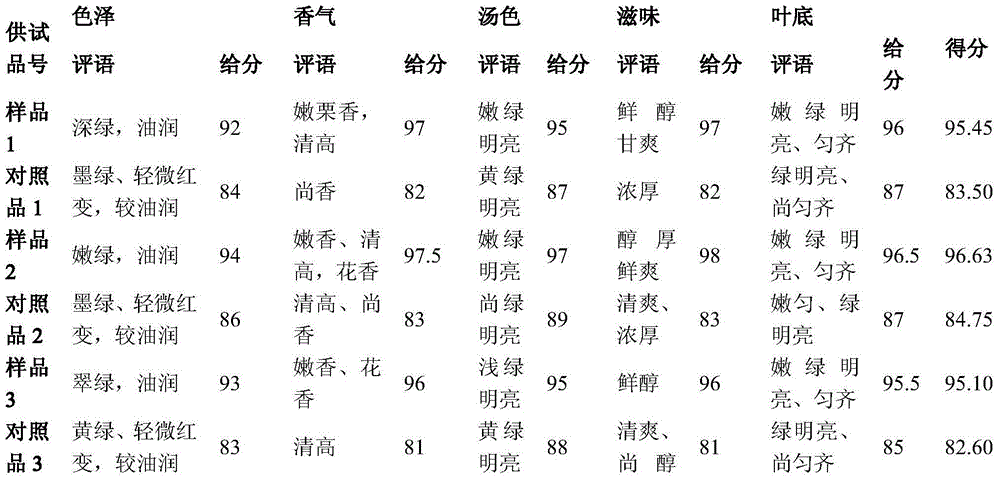

Examples

Embodiment 1

[0031] The processing method of a kind of green tea described in this embodiment is composed of the following steps: grading of fresh tea leaves → greening → greening → kneading to shape → initial fire drying → sufficient fire to enhance fragrance. The above steps are described in detail below:

[0032] 1. Classification of fresh tea leaves: Detect impurities and old stalks in fresh tea leaves, and classify according to the number of buds and leaves: divide one bud with one leaf and one bud with two leaves into Group A, and those with one bud with three leaves and above are divided into Group B.

[0033] 2. Greening: It consists of two processes of shaking greens and drying greens in turn. Among them, the shaking greens process uses a long-drum continuous greening machine, and uses electric heating to supply hot air into the cylinder; among them, the shaking time of fresh leaves of group A 1.5 minutes, the temperature of the hot air in the cylinder is 52°C, the shaking time of...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is:

[0044] 2. Greening: It consists of two processes of shaking greens and drying greens in sequence. Among them, the shaking greens process uses a long-drum continuous greening machine, and uses electric heating to supply hot air into the cylinder; among them, the fresh leaves of group A and the tea leaves of group B The shaking time of fresh leaves is 2 minutes, and the temperature of the hot air in the cylinder is 50°C; after the shaking is completed, the shaken green leaves are transported out of the leaves through the conveyor belt and enter the drying process under the cooling air blown by the fan.

[0045] The drying process is carried out in the green drying room: open the window of the drying room for ventilation, and use the air conditioner to control the ambient temperature if necessary, so that the fresh tea leaves of group A and group B are both at 20°C, and spread with multi-layer bamboo mats Put it...

Embodiment 3

[0055] The difference between this embodiment and embodiment 1 is:

[0056] 2. Greening: It consists of two processes of shaking greens and drying greens in turn. Among them, the shaking greens process uses a long-drum continuous greening machine, and uses electric heating to supply hot air into the cylinder; among them, the shaking time of fresh leaves of group A 2 minutes, the temperature of the hot air in the cylinder is 50°C, the shaking time of the fresh tea leaves of group B is 2.5 minutes, and the temperature of the hot air in the cylinder is 46°C; , into the drying process.

[0057] The green drying process is carried out in the green drying room: open the window of the green drying room to ventilate, and use air conditioners to control the ambient temperature if necessary, so that the fresh tea leaves of group A and group B are both at 10°C, and spread with multi-layer bamboo mats Put it, spread it out to a thickness of 13 cm, and let it dry for 70 minutes.

[0058]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com